Method for reducing viscose bubble for preparatory work of linear cutting

A working method and wire-cutting technology, applied in the direction of working accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of long time required, reduce chip drop rate, and low work efficiency, so as to reduce negative impact and shorten drying time. time and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

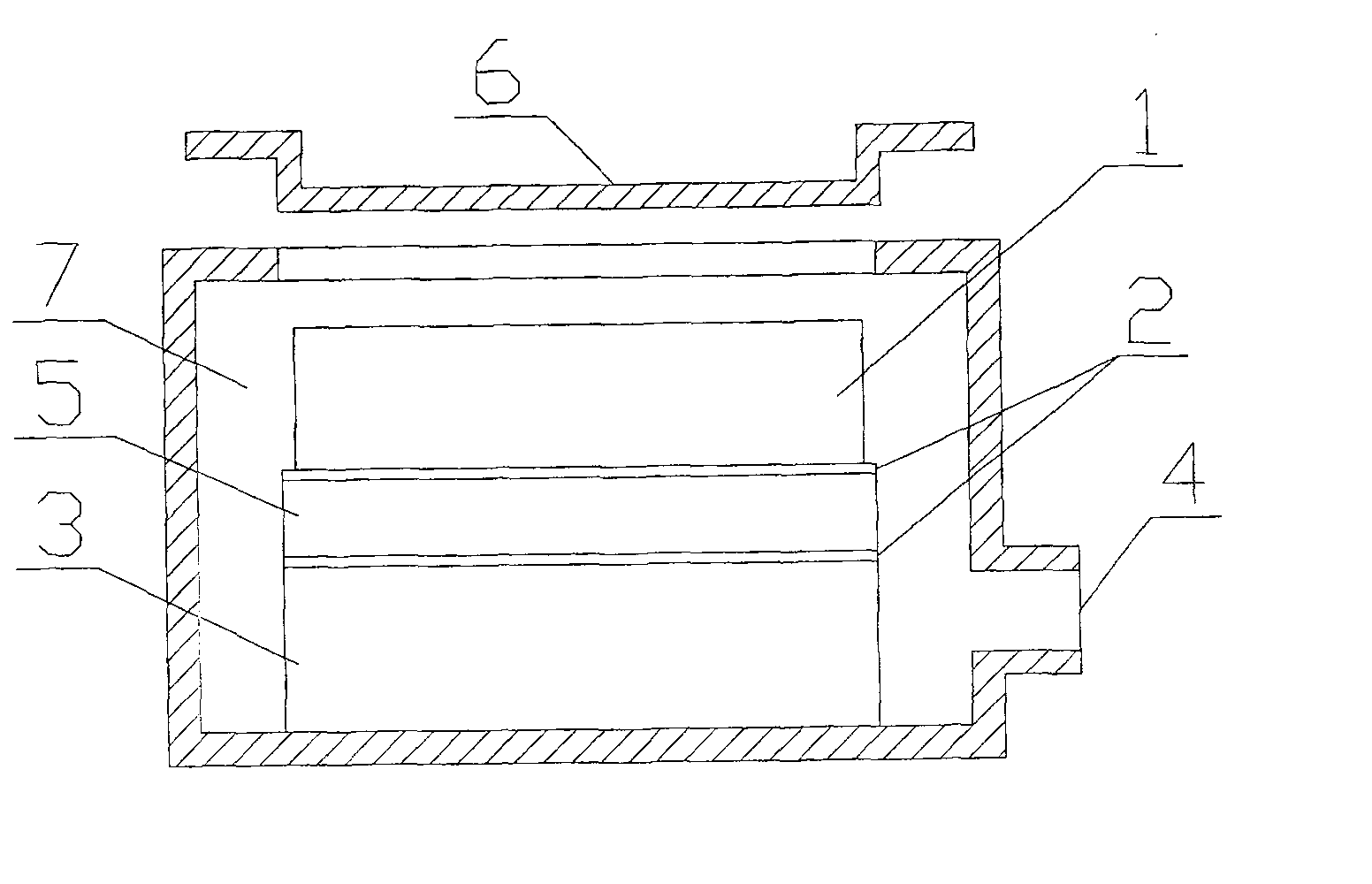

Image

Examples

Embodiment 1

[0035] Embodiment 1, a kind of method for wire cutting preparatory work reduces viscose bubble, wherein: the steps are as follows:

[0036] (1) Place the mounting parts and the object to be cut that are bonded together in a device with a negative pressure function.

[0037] (2) Reduce the air bubbles of the adhesive between the mounting parts and the object to be cut in a negative pressure environment.

Embodiment 2

[0038] Embodiment 2. A method for reducing glue bubbles in preparatory work for wire cutting, wherein: pretreatment is carried out before the installation parts and objects to be cut bonded to each other are installed on the wire cutting equipment, and the steps of pretreatment are as follows :

[0039] (1) Place the mounting parts and the object to be cut that are bonded together in a device with a negative pressure function;

[0040] (2) Adjust the negative pressure technical parameters to vacuumize;

[0041] (3) Reduce the air bubbles of the adhesive between the mounting parts and the object to be cut in a negative pressure environment.

Embodiment 3

[0042] Embodiment 3. A method for reducing glue bubbles in preparatory work for wire cutting, wherein: pre-treatment is performed before the installation parts and objects to be cut bonded to each other are installed on the wire cutting equipment, and the steps of pre-treatment are as follows :

[0043] (1) Brush glue on the contact surface between the object to be cut and the installation part;

[0044] (2) Place the mounting parts and the object to be cut that are bonded together in a device with a negative pressure function;

[0045] (3) Adjust the absolute pressure of the negative pressure technical parameters to be controlled at 0×10 5 Pa, the time control of negative pressure technical parameters is 0.1 minutes.

[0046] (4) Reduce the air bubbles of the adhesive between the mounting parts and the object to be cut in a negative pressure environment.

[0047] The object to be cut is a silicon block used in the fields of polycrystalline silicon, monocrystalline silicon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com