Modifier for high-pour-point crude oil

A modifier, crude oil technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of single anti-wax mechanism, difficult anti-wax effect of anti-wax agents, poor adaptability of anti-wax agents, etc. The effect of prolonged wax cycle, high pour point reduction and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

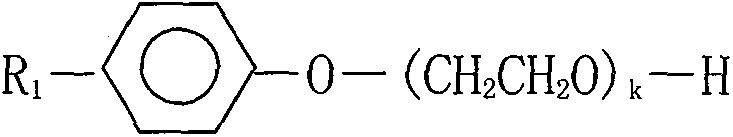

[0056] The preparation of the high pour point crude oil modifier of the present invention, put the alkylphenol polyoxyethylene ether and the AE type nonionic surfactant into the reaction kettle according to the ratio, add 10% to 15% xylene at the same time, and then heat up while stirring to 40°C, after being fully mixed, discharge and set aside.

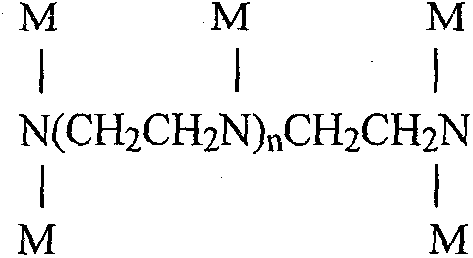

[0057] Add the wax-preventing pour point depressant, sodium petroleum sulfonate and AR-type nonionic surfactant to the reaction kettle according to the ratio, and add 11% to 72.5% xylene at the same time, and raise the temperature to 70°C while stirring. Add the above-mentioned materials with a good ratio, keep the addition in about 10 minutes, and then stir at a constant temperature for 30 minutes. After being fully mixed, cool down to below 40°C and discharge, and mix with alkylphenol polyoxyethylene ether and AE type nonionic in proportion The mixture of surfactants can be compounded to obtain a multi-effect and adaptable high po...

Embodiment 1

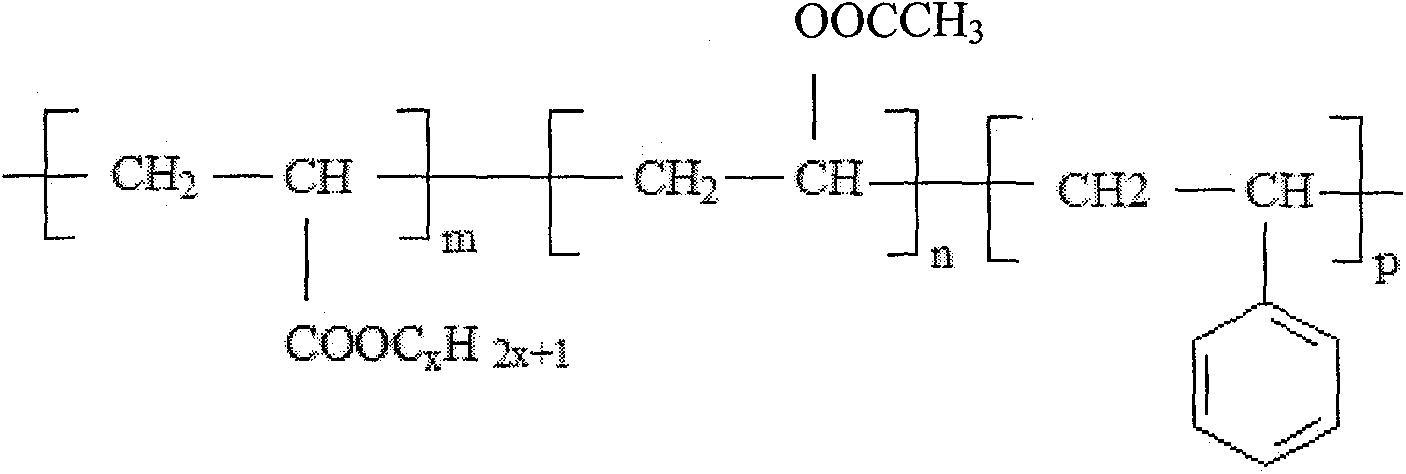

[0059] The anti-wax pour point depressant of the present invention adopts stearyl acrylate-vinyl acetate-styrene terpolymer (AVS-18) and behenyl acrylate-vinyl acetate-styrene terpolymer (AVS-22) The mixture, the ratio of the amount of AVS-18 and AVS-22 is 1:2, the mixture (AVS 18-22 ) was prepared as follows:

[0060] (1) mixed acrylate (A 18-22 ) preparation

[0061] Add 40ml of toluene, 0.3g of hydroquinone, 0.033mol of stearyl alcohol, and 0.067mol of behenyl alcohol into a 500ml four-necked flask equipped with a thermometer, stirrer, water separator and reflux condenser, and heat to 70 to After melting at 80°C, add 0.12mol of acrylic acid and 0.36g of p-toluenesulfonic acid in turn, heat and reflux at 110-120°C for 2.5h, continue to heat up to 140-160°C for constant temperature reaction, when the formed When the amount of water is equivalent to the theoretical value (about 1.8ml), then it is considered that the reaction is basically completed and the reaction is stoppe...

Embodiment 3

[0068] Example 3: When the water content of the crude oil is less than 10%, the optimal weight ratio of the materials is: 4% wax-preventing pour point depressant, 10% sodium petroleum sulfonate, 1% alkylphenol polyoxyethylene ether, AE type nonionic surface active Agent 2%, AR type nonionic surfactant 3%, and the rest is solvent.

[0069] Application objects: Well Zhanghai 21-21L in Dagang Tanhai Oilfield, water cut 1% to 5%, crude oil density 0.8539g / cm 3 , freezing point 29°C, viscosity 133.2mPa.s (29°C), wax precipitation point 41.3°C, wax content 10.6%, colloidal asphaltenes 7.5%; test results after indoor dosing 1‰, pour point reduction range 15°C, drop Viscosity rate is 77.8%, wax control rate is 88%; field application results, dosing 1‰, after field treatment, pour point reduction rate is 16°C, viscosity reduction rate is 80.5%, wax control rate is 86%, and wax removal cycle is extended by more than 10 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com