Polyether amine compound, preparation method thereof, and gasoline detergent

A technology of gasoline detergent and polyether amine, which is applied in the field of gemini polyether amine and its preparation, and gasoline detergent, which can solve problems such as difficulty in acceleration, difficulty in starting the engine, unstable idle speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

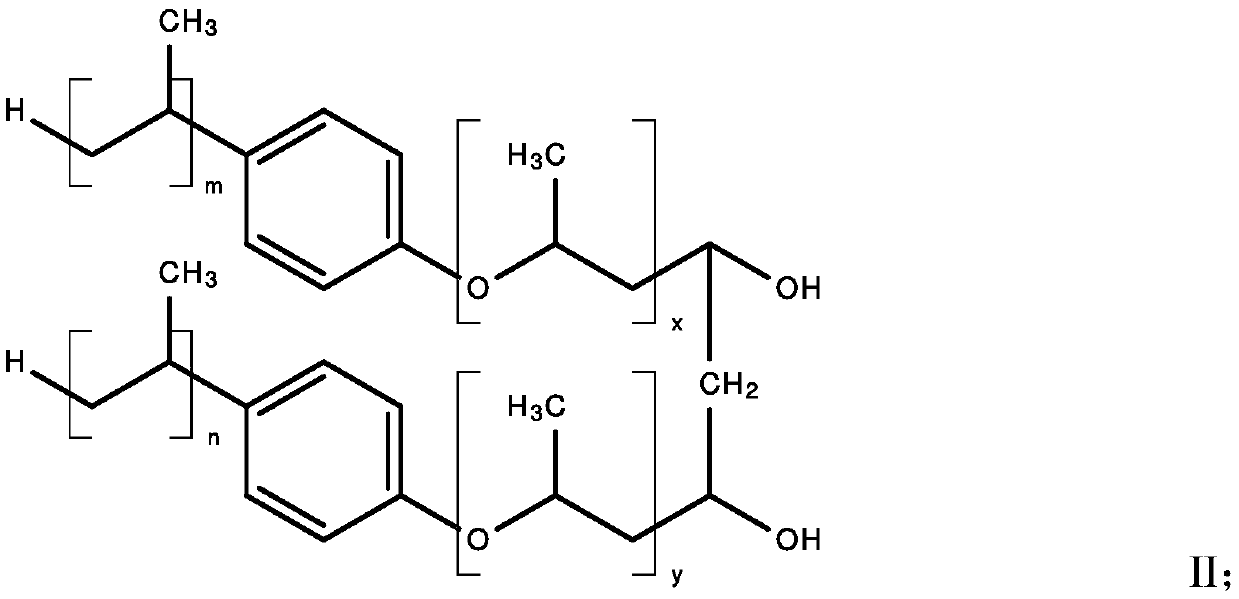

[0052] The invention provides a kind of preparation method of polyether amine compound, comprises the following steps:

[0053] 1) Under the action of the catalyst, after the dehydrogenation reaction of the gemini polyether alcohol, the gemini polyether ketone is obtained;

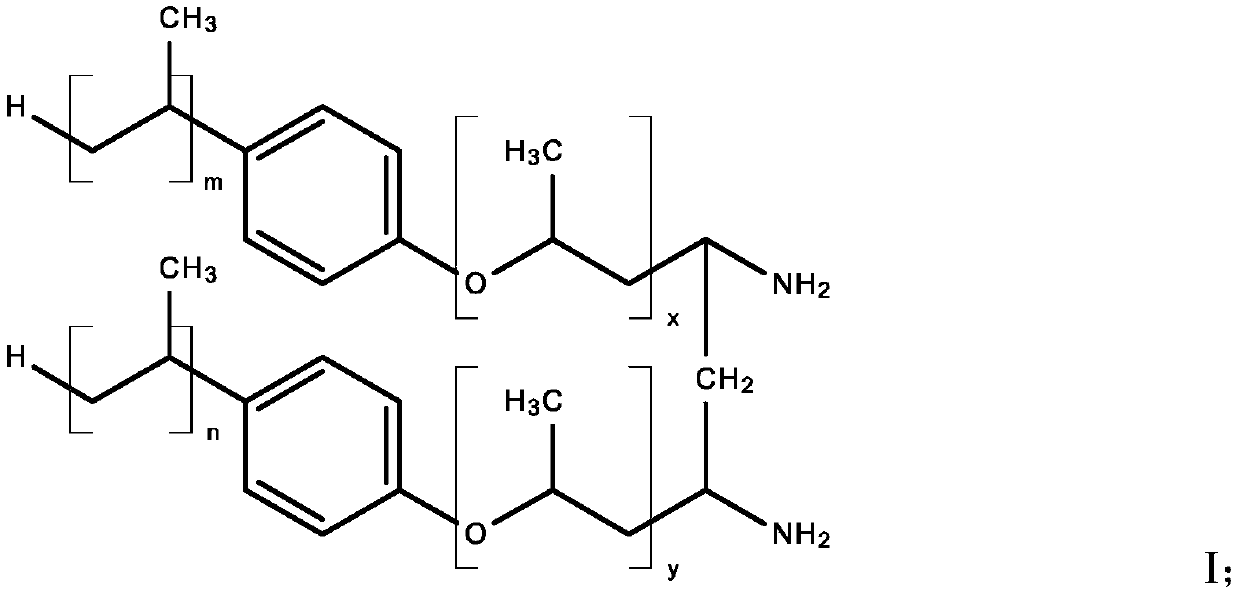

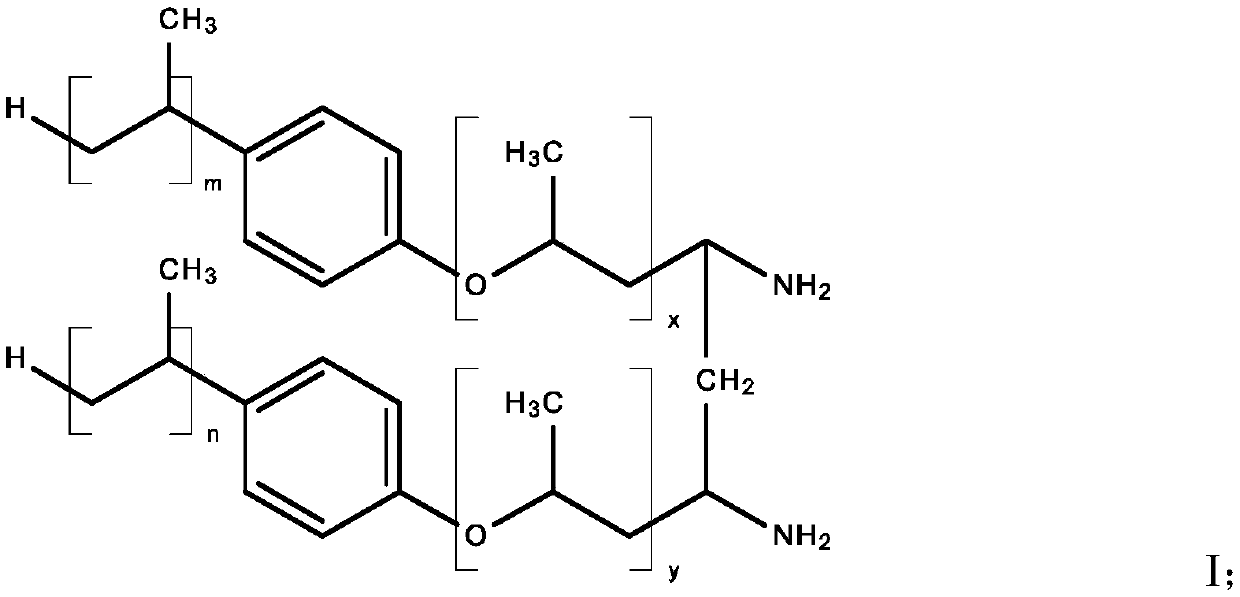

[0054] 2) Under the condition of hydrogen, after the gemini polyether ketone obtained in the above steps, the catalyst, calcium oxide and liquid ammonia are subjected to amination reaction, a polyetheramine compound having a structure shown in formula I is obtained;

[0055]

[0056] Wherein, the m=3-10, n=3-10, x=5-15, y=5-15.

[0057] In the above-mentioned preparation method of the present invention, the structure of the material, the selection of parameters and the preferred range thereof are consistent with those of the aforementioned polyetheramine compounds, and the selection of parameters and the preferred range thereof will not be repeated here.

[0058] In the present invention, firstly, under ...

Embodiment 1

[0086] Add gemini polyether alcohol (wherein, m=4, n=4, x=7, y=8) to the high-temperature and high-pressure reactor, add Raney nickel catalyst accounting for 3% of the mass of gemini polyether alcohol, vacuumize, 235°C After reacting for 19 hours, purging with nitrogen, and then filtering to obtain gemini polyether ketone.

[0087] Add gemini polyether ketone to the high-temperature and high-pressure reaction kettle, add a Raney nickel catalyst accounting for 6% of the mass of gemini polyether ketone, add calcium oxide with twice the molar number of gemini polyether ketone, and vacuumize. Introduce hydrogen gas with twice the mole number of Gemini polyether ketone, add liquid ammonia with twice the mole number of Gemini polyether ketone, recover unreacted hydrogen and ammonia after reacting at 210°C for 8 hours, filter and rotary evaporate to obtain a new type of Gemini polyether amine, Yield 95.2%.

[0088] Add 85% of Shell Heineken synthetic oil, 4.8% of BASF's highly activ...

Embodiment 2

[0095] Add gemini polyether alcohol (wherein, m=3, n=3, x=6, y=7) to the high-temperature and high-pressure reactor, add Raney nickel catalyst accounting for 3% of the mass of gemini polyether alcohol, vacuumize, 235°C After reacting for 19 hours, purging with nitrogen, and then filtering to obtain gemini polyether ketone.

[0096] Add gemini polyether ketone to the high-temperature and high-pressure reaction kettle, add a Raney nickel catalyst accounting for 6% of the mass of gemini polyether ketone, add calcium oxide with twice the molar number of gemini polyether ketone, and vacuumize. Introduce hydrogen gas with twice the mole number of Gemini polyether ketone, add liquid ammonia with twice the mole number of Gemini polyether ketone, recover unreacted hydrogen and ammonia after reacting at 210°C for 8 hours, filter and rotary evaporate to obtain a new type of Gemini polyether amine, Yield 94.7%.

[0097] Add 85% of Shell Heineken synthetic oil, 4.8% of BASF's highly activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com