Water-cooling head structure

A technology of water cooling head and heat exchange device, which is applied in the direction of cooling/ventilation/heating transformation, instrumentation, electrical digital data processing, etc., and can solve the problems of reducing the volume of water cooling and heat dissipation systems, reducing volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

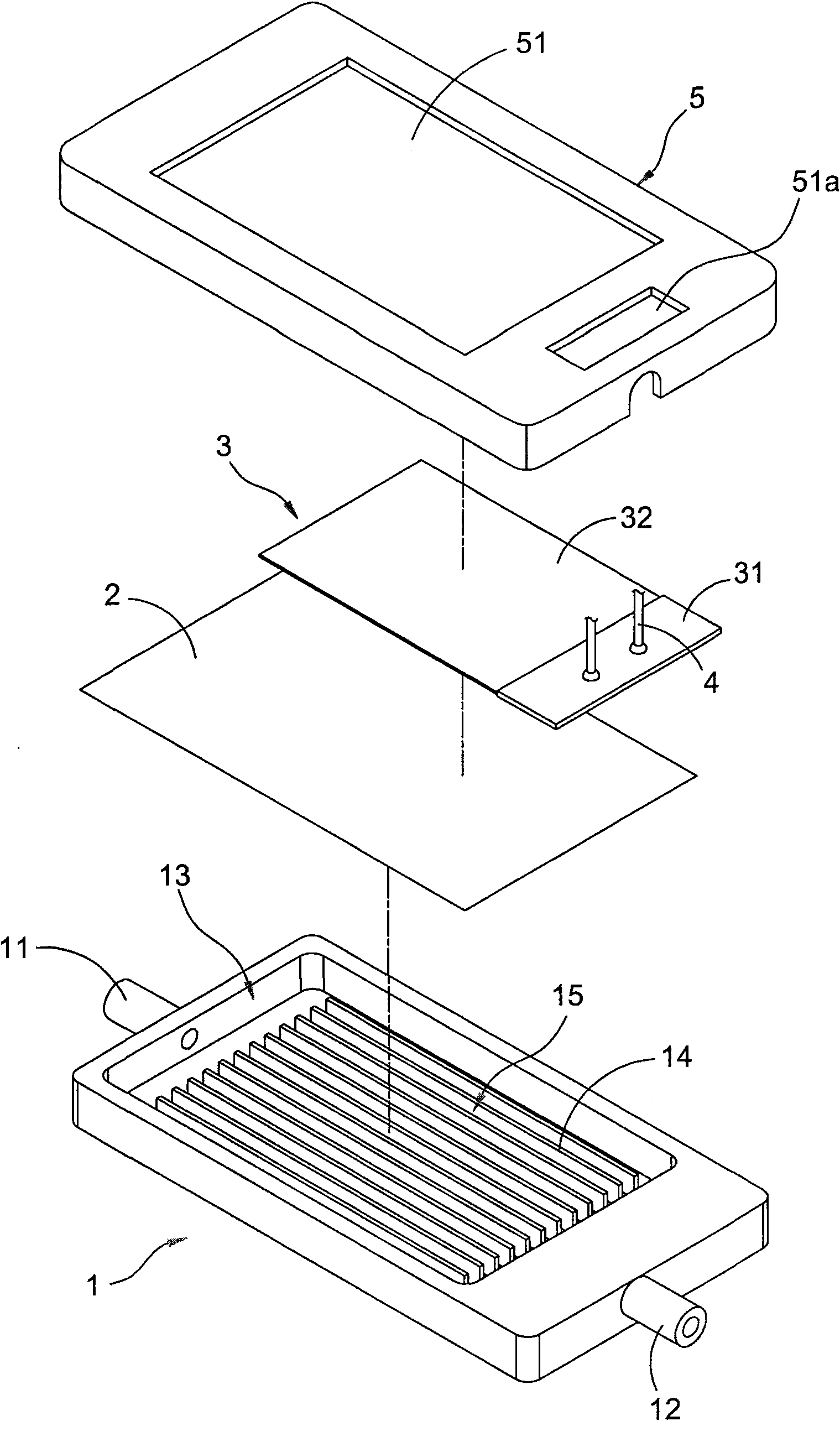

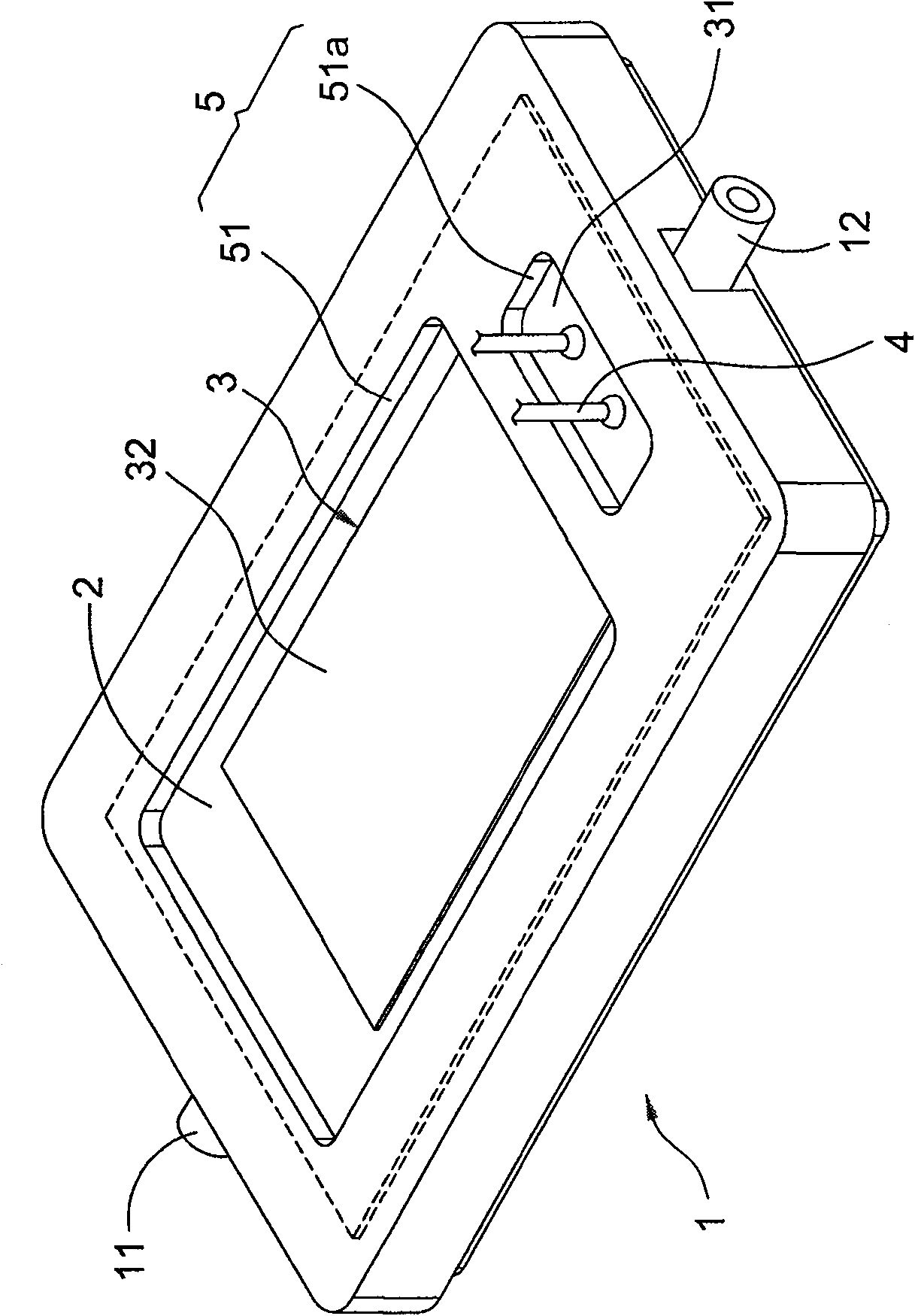

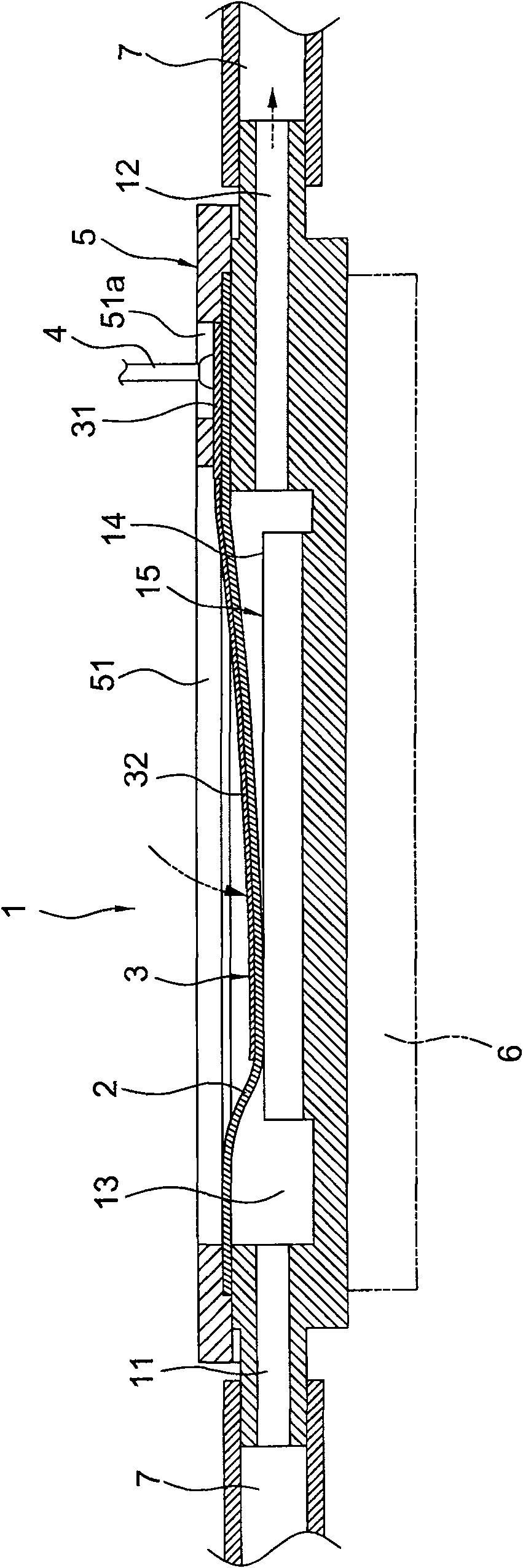

[0019] see figure 1 and figure 2 , is the three-dimensional structure exploded view and combined completed view of the present invention. As shown in the figure, the water cooling head of the present invention is mainly based on a cavity 1, and the left and right sides of the cavity 1 are respectively provided with a water inlet pipe 11 and a water outlet pipe 12, and in the cavity 11 The inside is provided with a chamber 13, and the chamber 13 is connected with the water inlet pipe 11 and the water outlet pipe 12 respectively; and a heat exchange device 14 is arranged in the chamber 13, wherein the The heat exchanging device 14 is composed of a plurality of cooling fins arranged at intervals, and any two adjacent cooling fins form a cooling channel 15 .

[0020] continued see figure 1 , a film 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com