Multilayer circuit board and method for fabricating same

A technology of multilayer circuit board and manufacturing method, which is applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems that cannot meet the requirements of high-density installation, achieve low cost, realize high-density installation, electrical Easy to attach effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

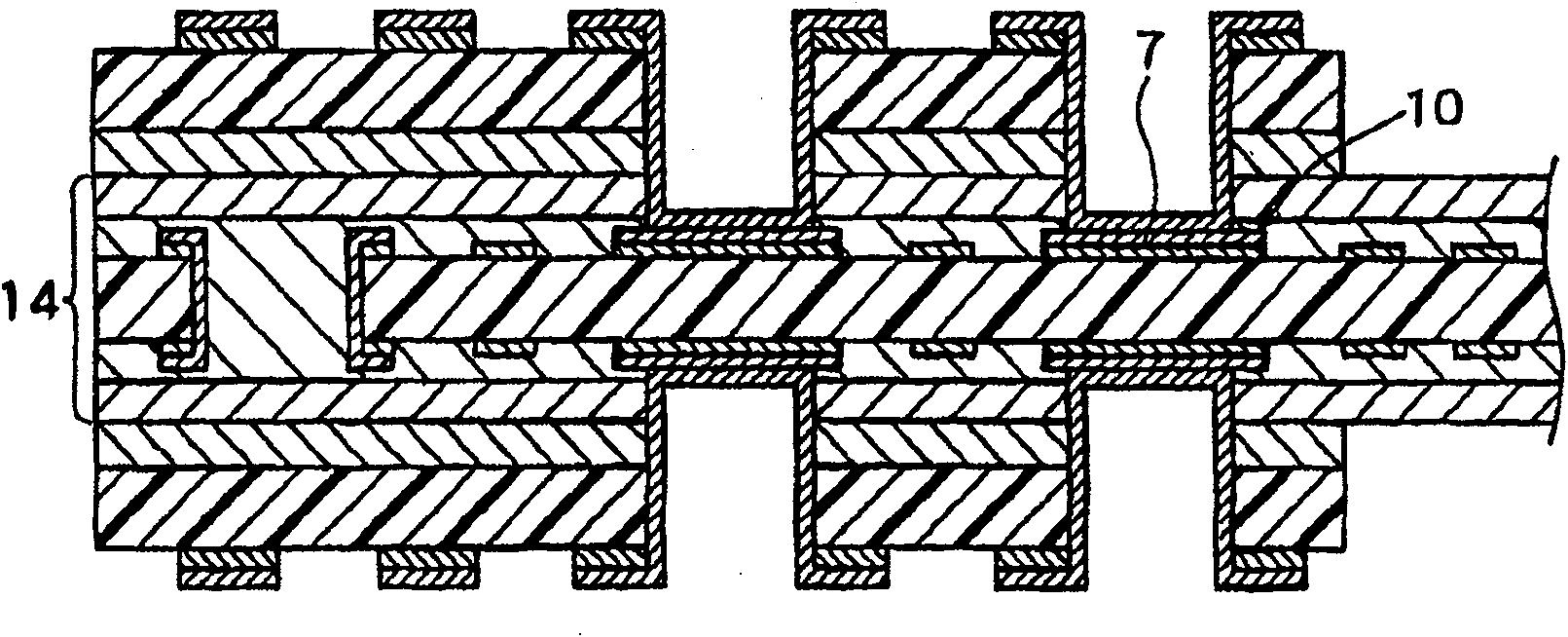

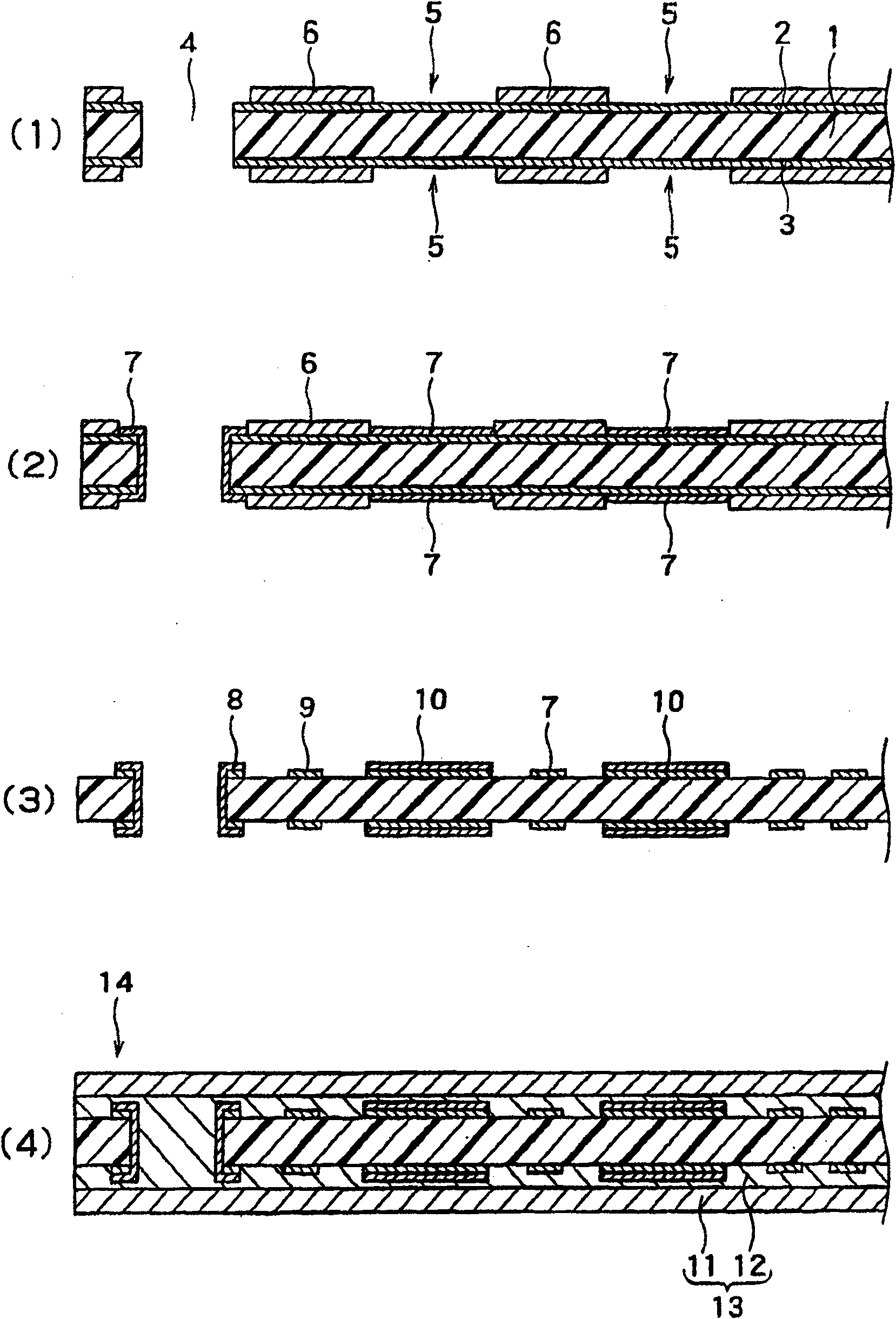

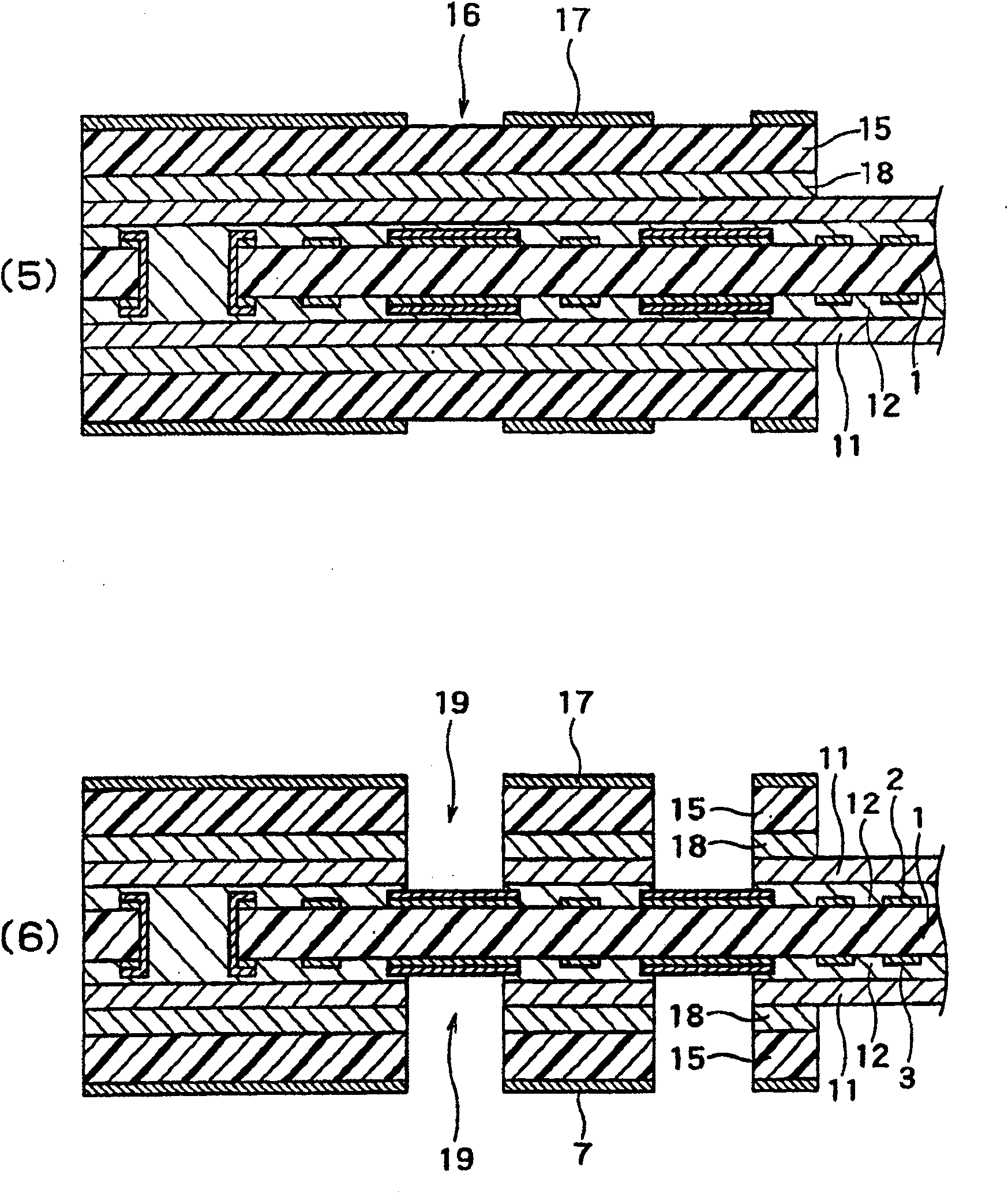

[0053] figure 1is a conceptual sectional configuration diagram showing the structure of a multilayer circuit board according to Embodiment 1 of the present invention. In this embodiment 1, the single-sided outer layer circuit board is laminated on the inner layer double-sided core board 14, and the inner layer circuit and the circuit of the reinforced outer layer circuit board are connected with a bottomed blind hole to form a structure.

[0054] In this multilayer circuit board, both the inner layer circuit board and the outer layer circuit board use a flexible base material for a flexible circuit board, and a part of the flexible inner layer double-sided circuit board extends to the outside of the multilayer part, Become a flexible multilayer circuit board that forms part of the cable.

[0055] Thus, the first embodiment is characterized in that the electrolytic plated film 7 is formed on the blind hole receiving platform portion 10 that electrically connects the circuit o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com