Optical cable and transmitting/receiving sub-assembly

A technology for transmitting and receiving components and optical cables, which is applied in the direction of optical components, optics, light guides, etc., to achieve the effects of increased design freedom, high-density installation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

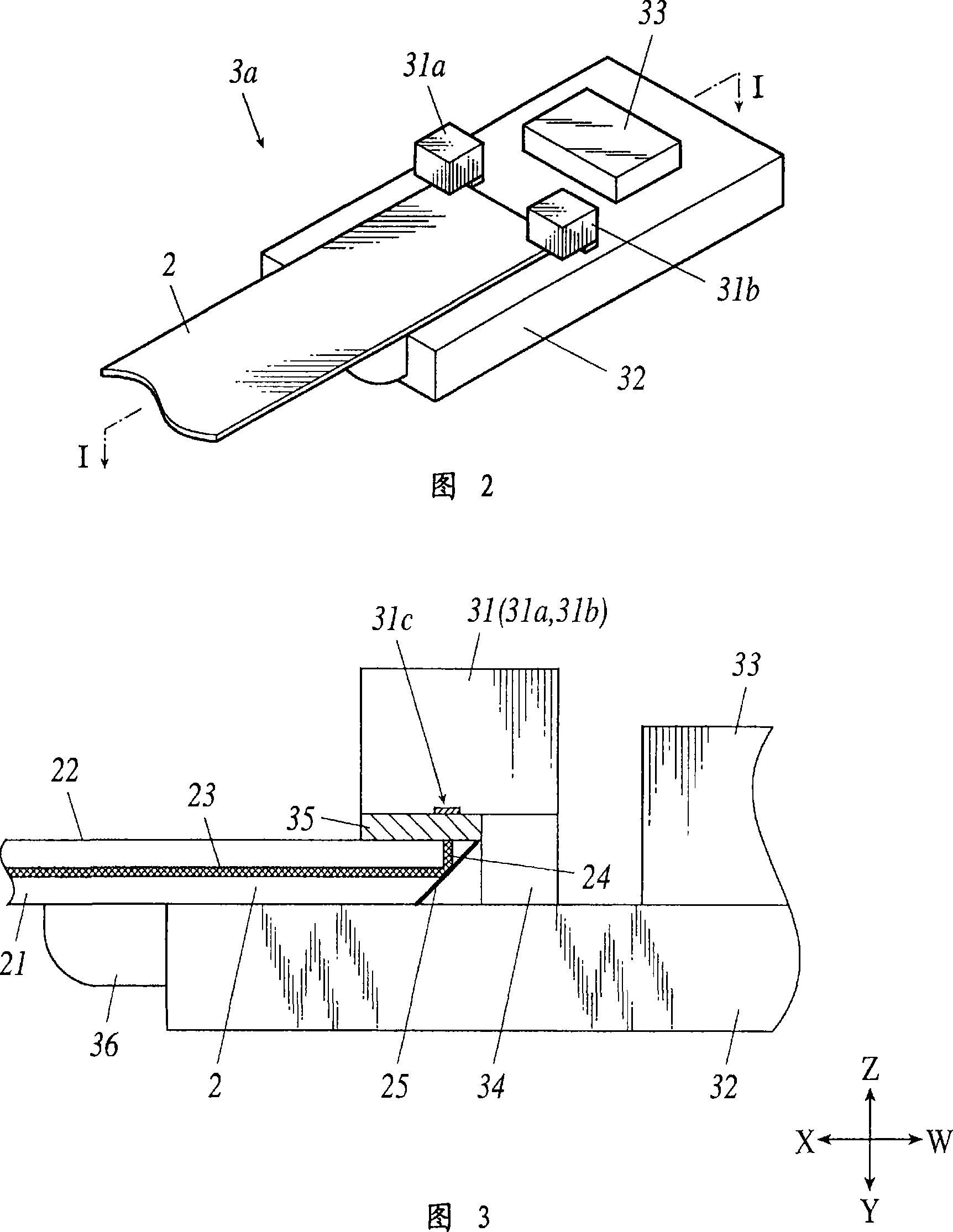

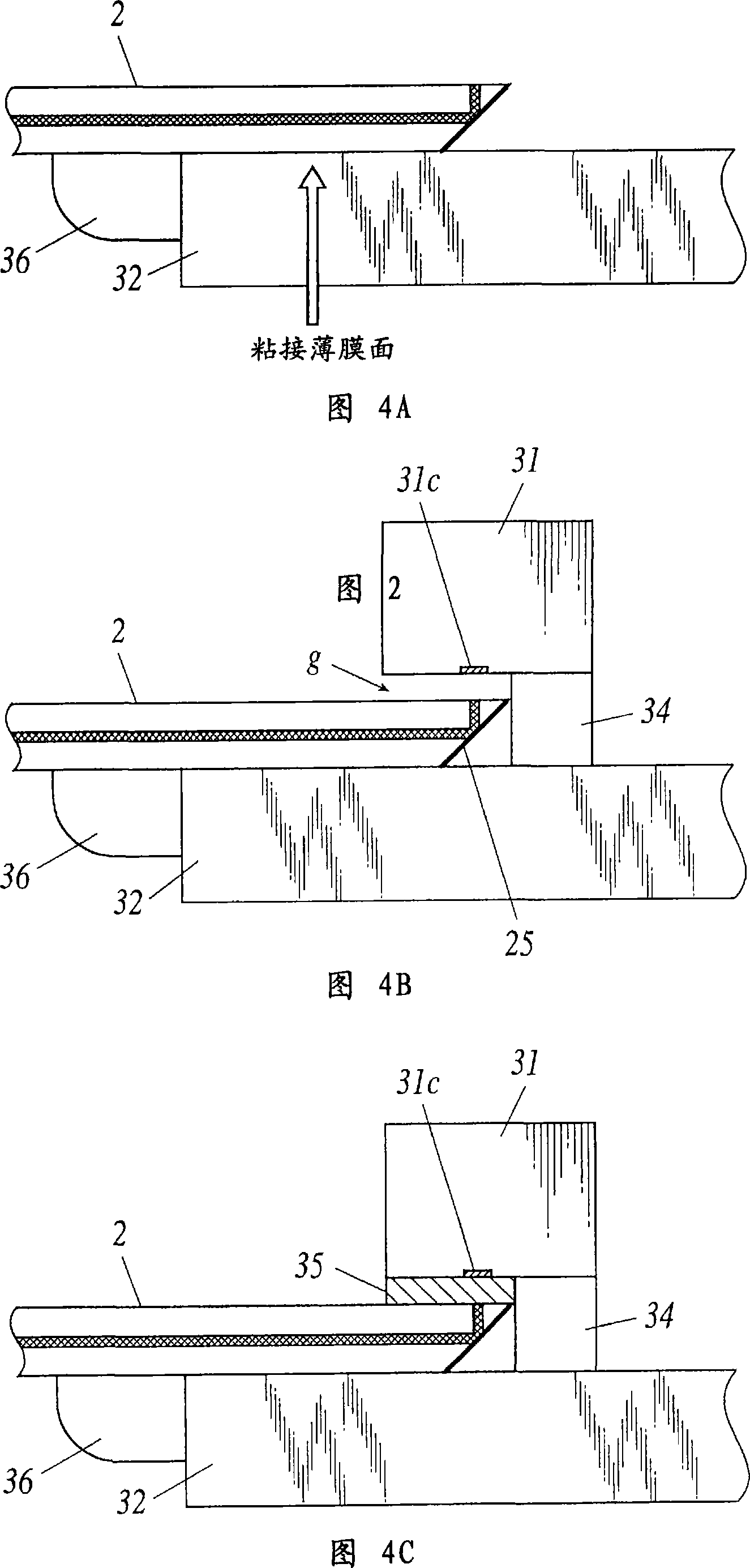

[0034] (Structure of optical cable and connector part)

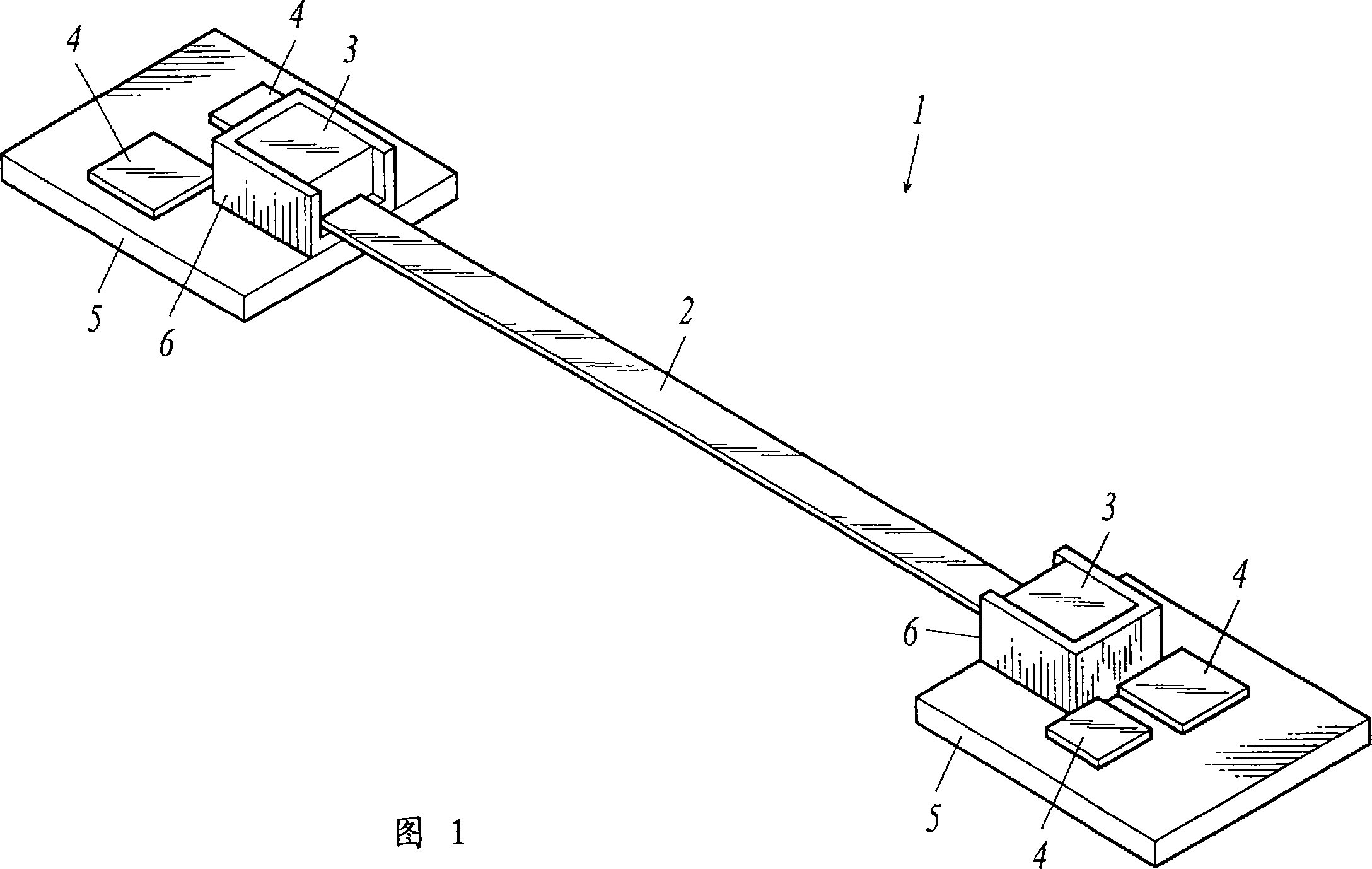

[0035] FIG. 1 shows the structure of an optical cable 1 according to this embodiment.

[0036] As shown in FIG. 1 , an optical cable 1 is a component for connecting two printed wiring boards 5 , and is configured to include connectors 3 at both ends of an optical waveguide cable 2 . The connector 3 is mounted on the socket 6 mounted on the printed wiring board 5 , and the IC 4 is additionally mounted on the printed wiring board 5 .

[0037] The optical waveguide cable 2 is formed in a film shape, and the optical waveguide included therein functions as a transmission path for light exchanged between connectors 3 provided at both ends. The connector 3 is equipped with a transceiver component for photoelectric conversion, and the transceiver component converts the electrical signal input from the printed circuit wiring substrate 5 into light, and sends the light to the connector 3 on the other end side by means of the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com