Straight-through motherboard socket and manufacturing method thereof

A motherboard and socket technology, applied in the direction of coupling devices, electrical components, connections, etc., can solve the problems that cannot be reduced, the manufacturing process is laborious and time-consuming, and the opening area cannot be reduced, so as to achieve the effect of reducing the area and high-density installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

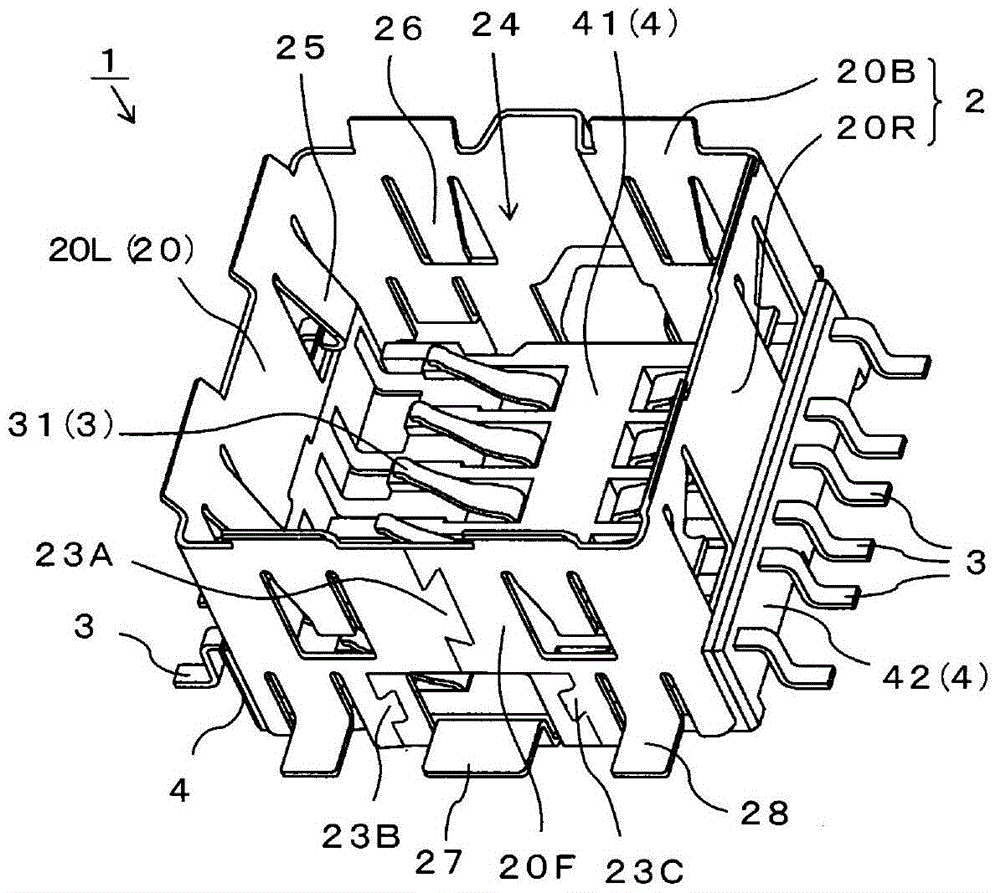

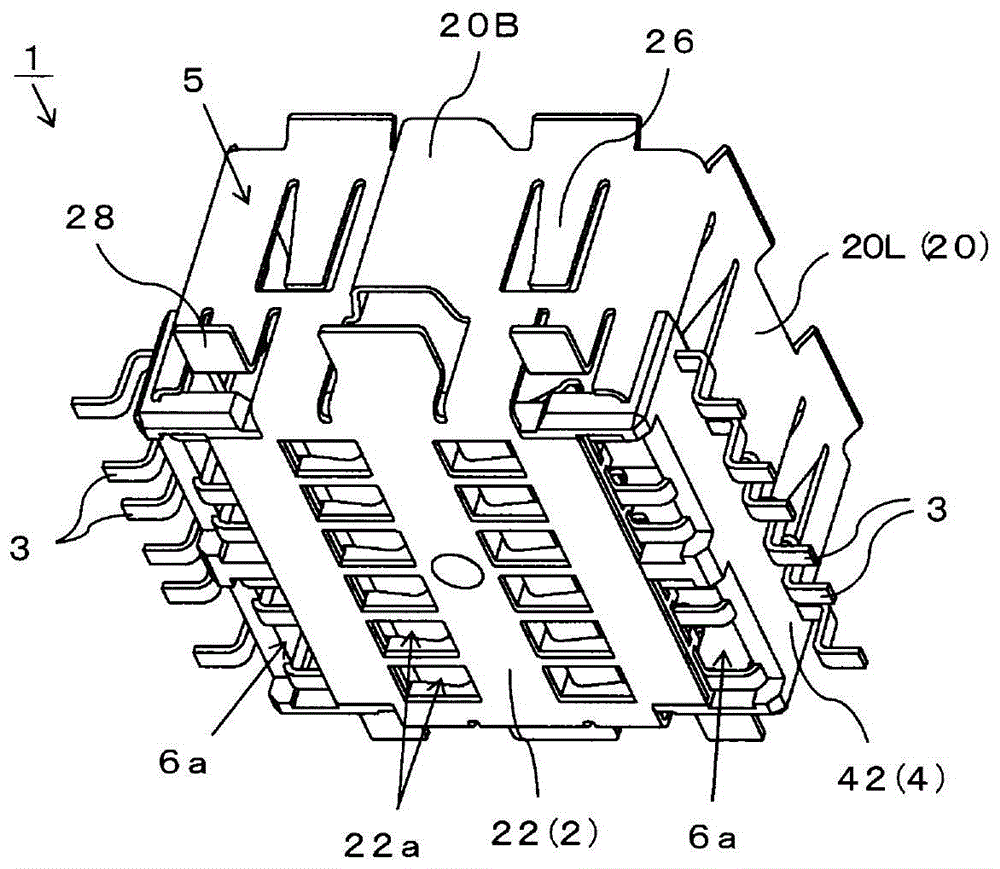

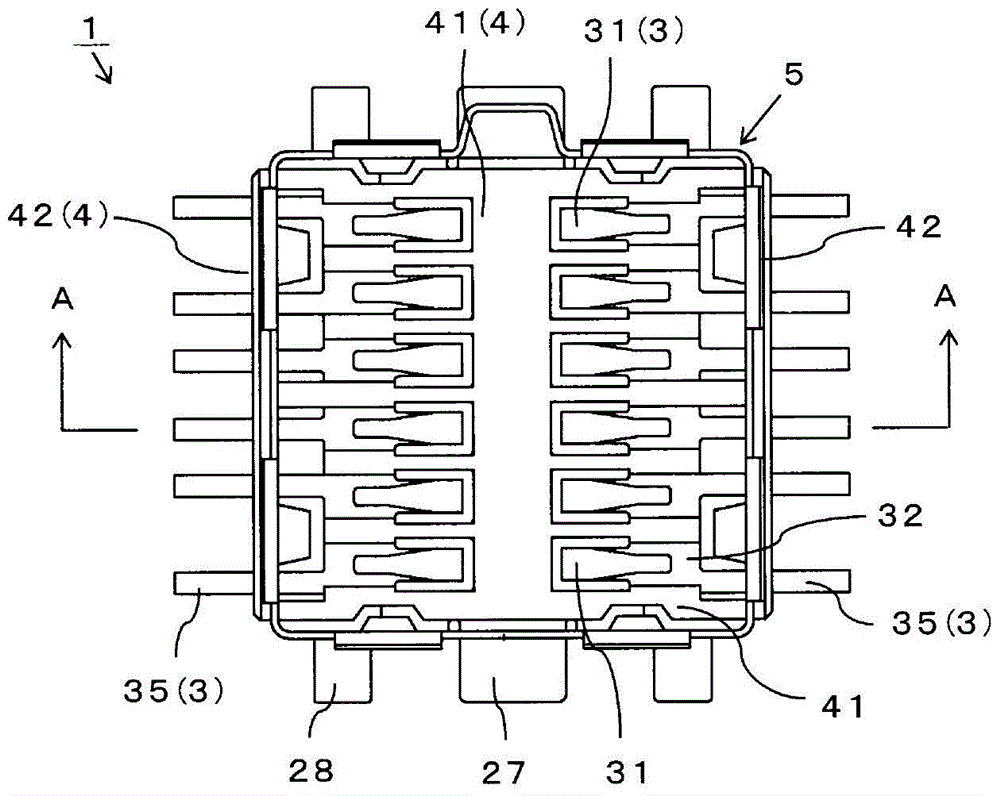

[0103] Refer below Figure 1 to Figure 9 The pass-through motherboard socket 1 and its manufacturing method related to an embodiment of the present invention will be described. The embodiments described below are suitable specific examples of the present invention. Although various technical limitations are made on the constituent elements, types, combinations, shapes, relative configurations, etc., these are merely examples, and the present invention is not limited thereto. .

[0104] The through motherboard socket 1 is installed in the housing of the portable telephone Figure 4 The mounting hole 121 of the printed circuit board 120 is used to connect the camera module (not shown) stored in the upper part of the figure to the printed circuit board 120, and connect the parts of the main board socket 1 on the lower side. In the description, Figure 4 The directions shown are the up, down, left, and right directions. Figure 4 The paper faces the inside direction as the back and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com