Revolving electricity loss control apparatus of tower crane

A tower crane and electric control technology, applied in cranes and other directions, can solve problems such as hidden safety hazards and uncontrollable problems, and achieve the effect of preventing collision accidents and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

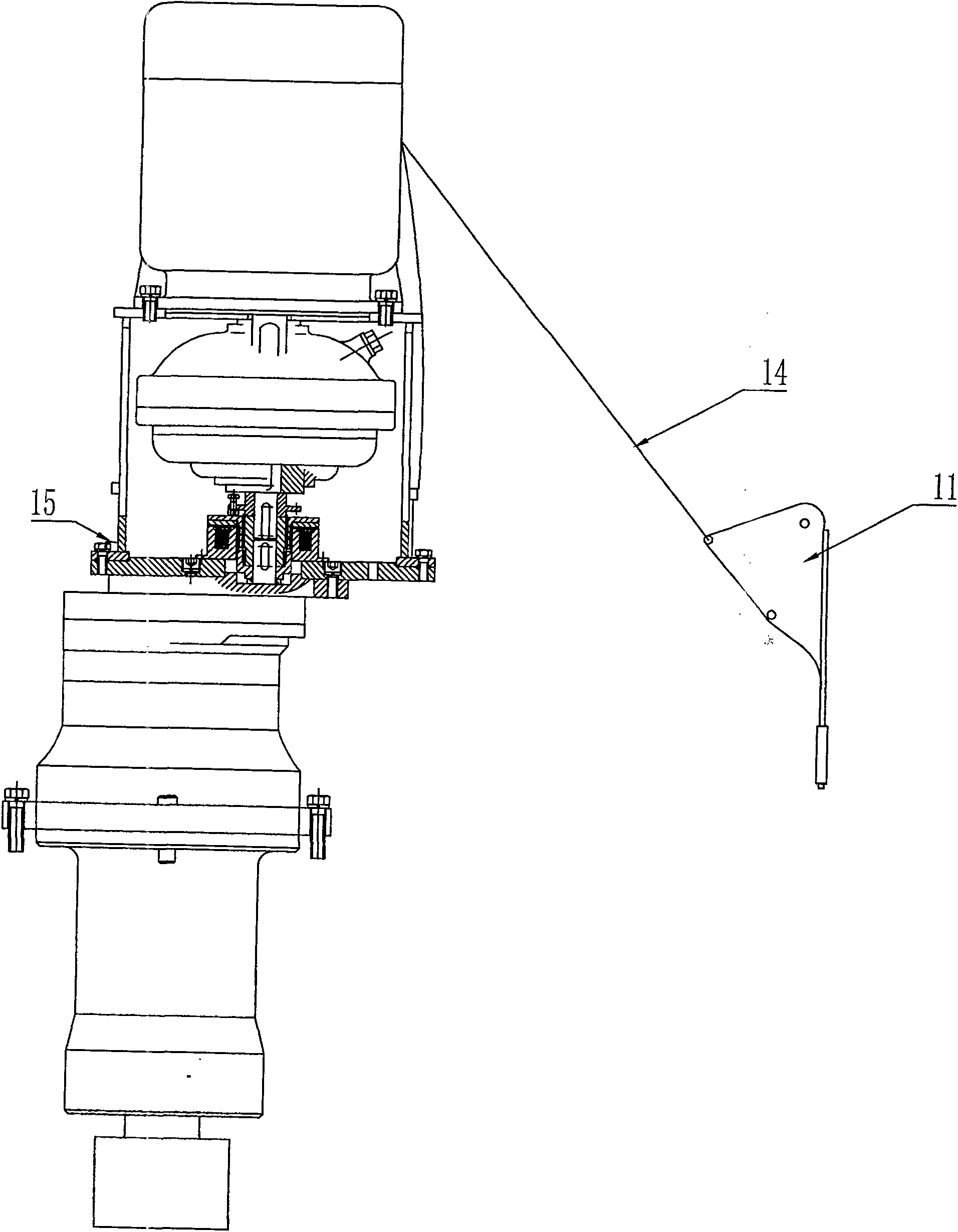

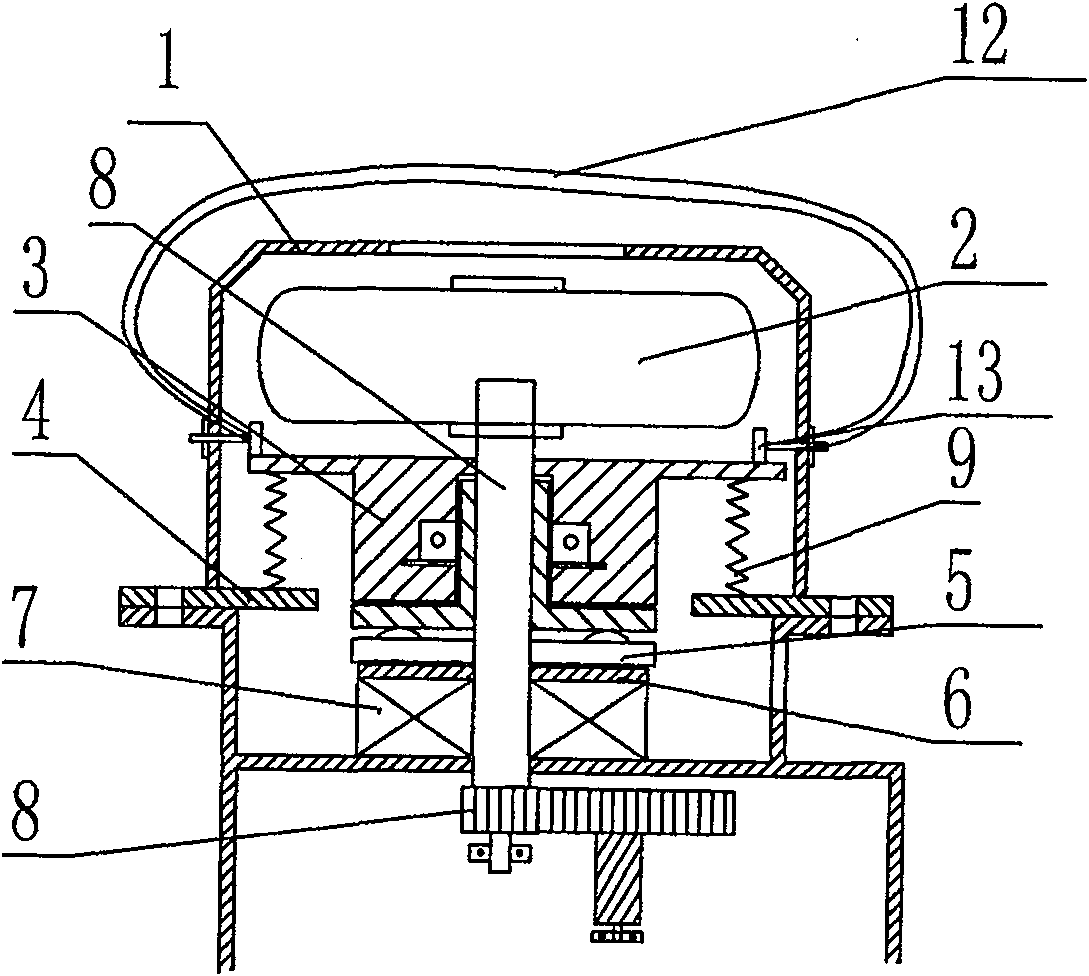

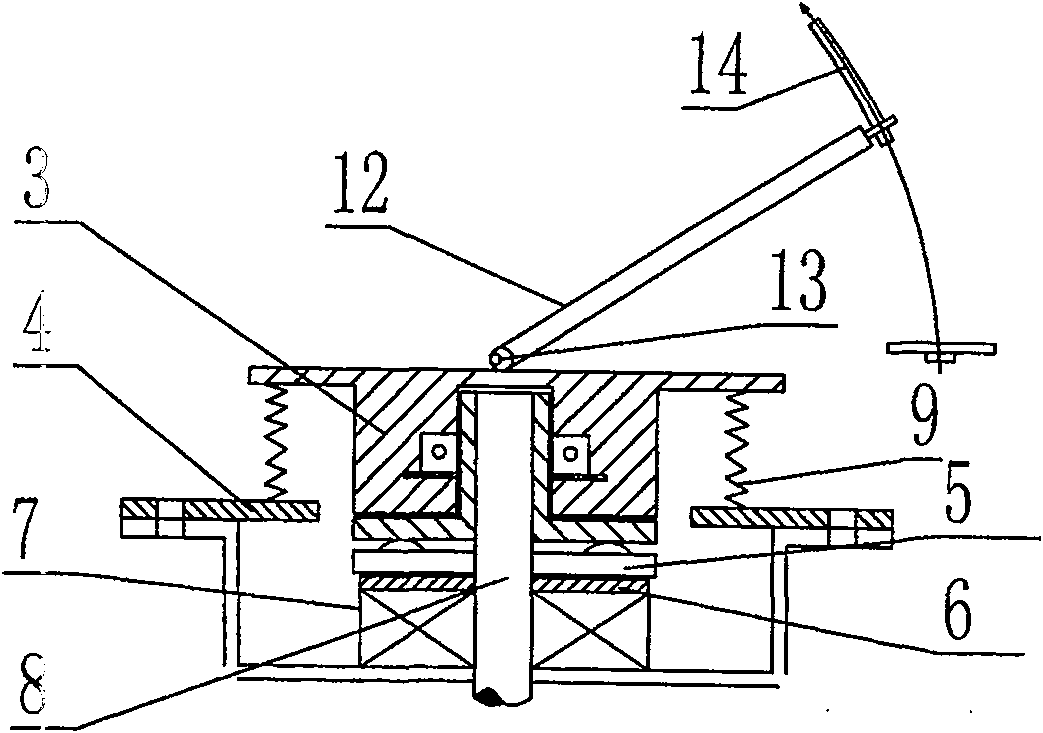

[0014] refer to Figure 1-Figure 4 , a tower crane rotary power loss control device, including a casing 1, a hydraulic coupling impeller 2 installed in the casing, a gland 3, a bottom cover 4, a brake steel plate 5, a friction plate 6 and an electromagnetic coil 7. The hydraulic coupler impeller 1 is installed on the upper end of the main shaft 8, and the main shaft 8 is sequentially fitted with a gland 3, a brake steel plate 5, a friction plate 6 and an electromagnetic coil 7 from top to bottom. The gland 3 Fixedly connected with the brake steel plate 5, the brake steel plate 5 cooperates with the friction plate 6, the friction plate 6 is fixedly connected with the brake steel plate 5, and the gland 3 is connected with the bottom cover 4 through the return spring 9 , the bottom cover 4 is installed in the casing 1, the output gear 10 is installed at the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com