Vehicle body rear part structure

一种车体、后部的技术,应用在车体后部构造领域,能够解决不能得到充分的加强等问题,达到提高刚性、抑制上方弯折的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

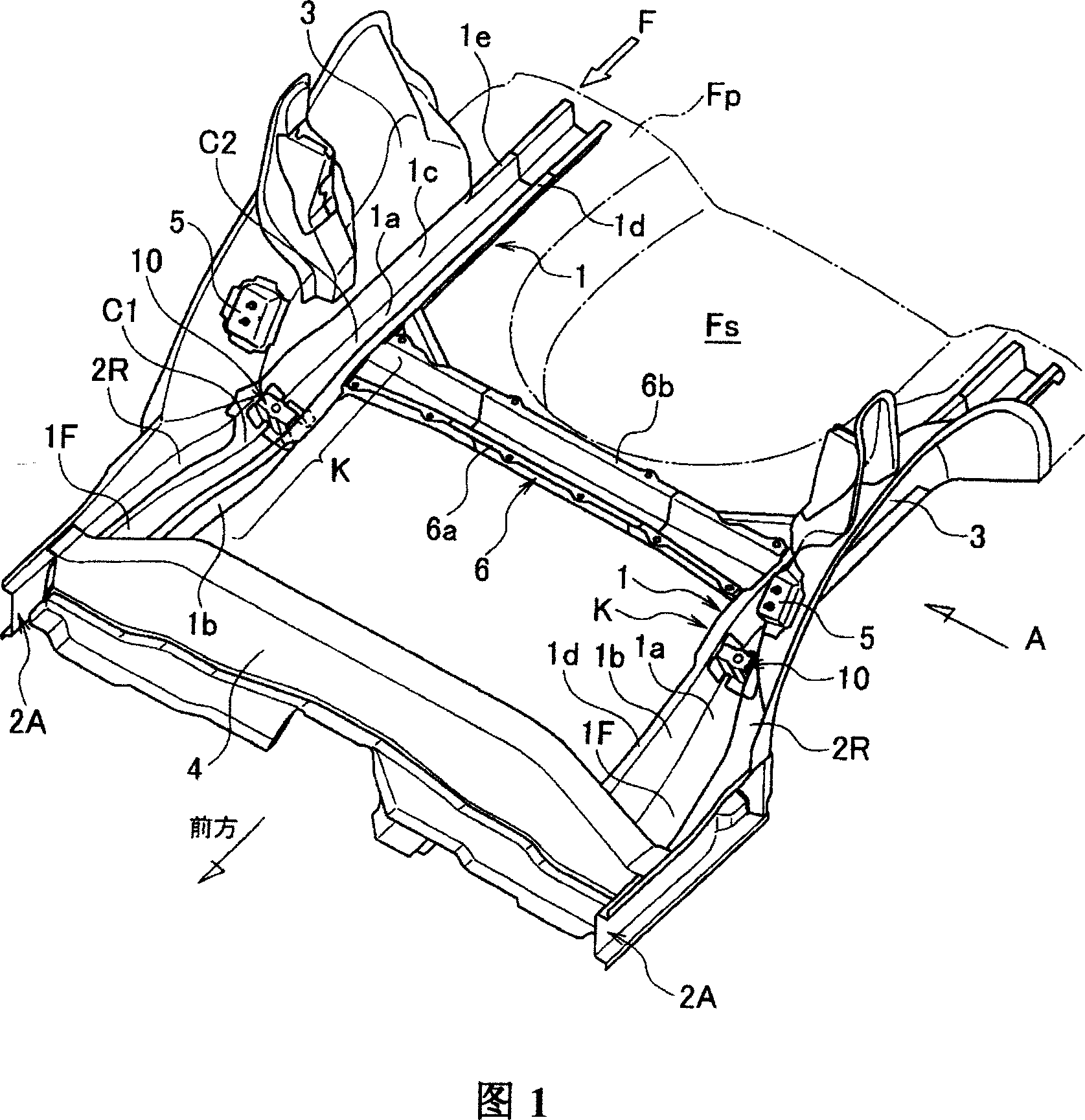

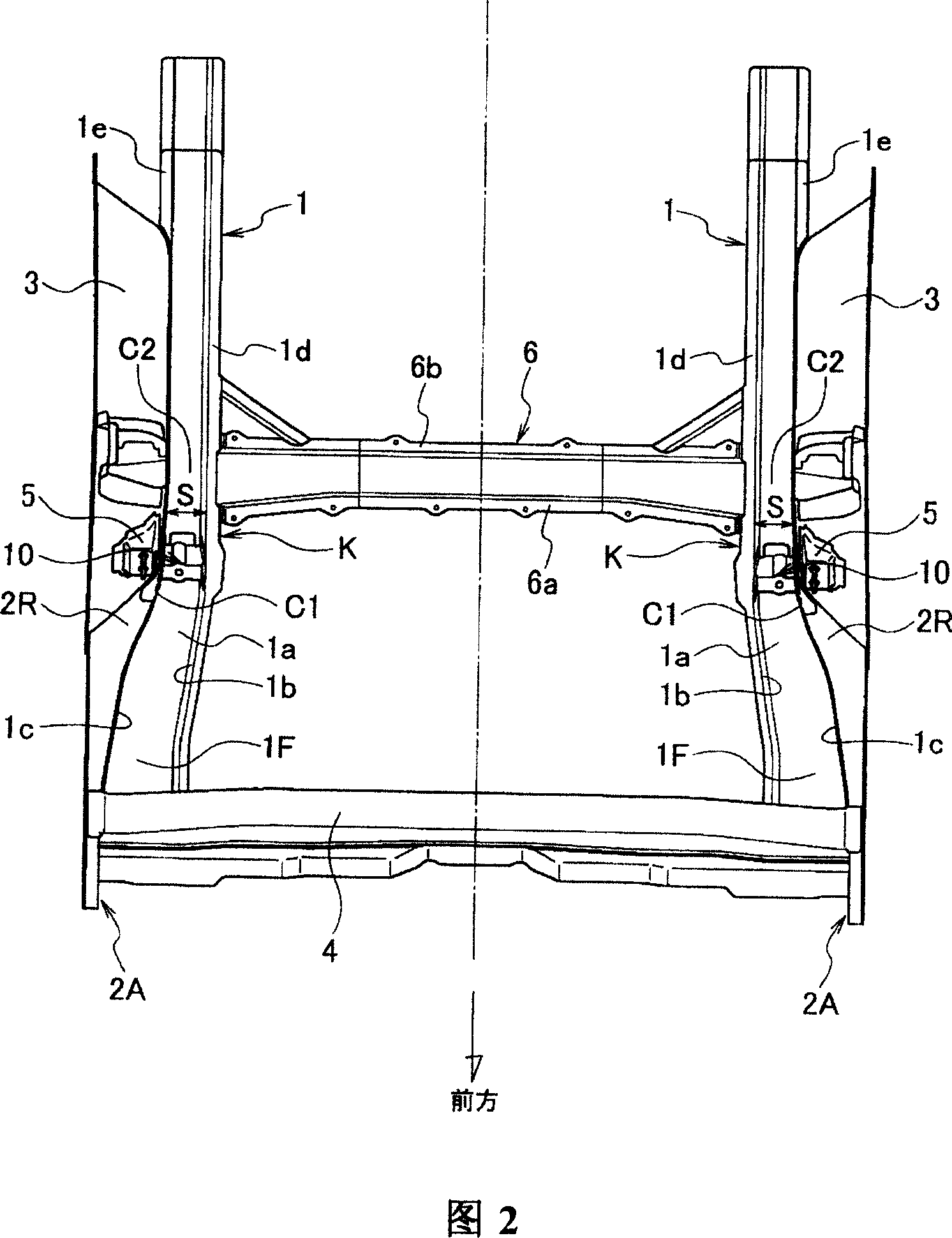

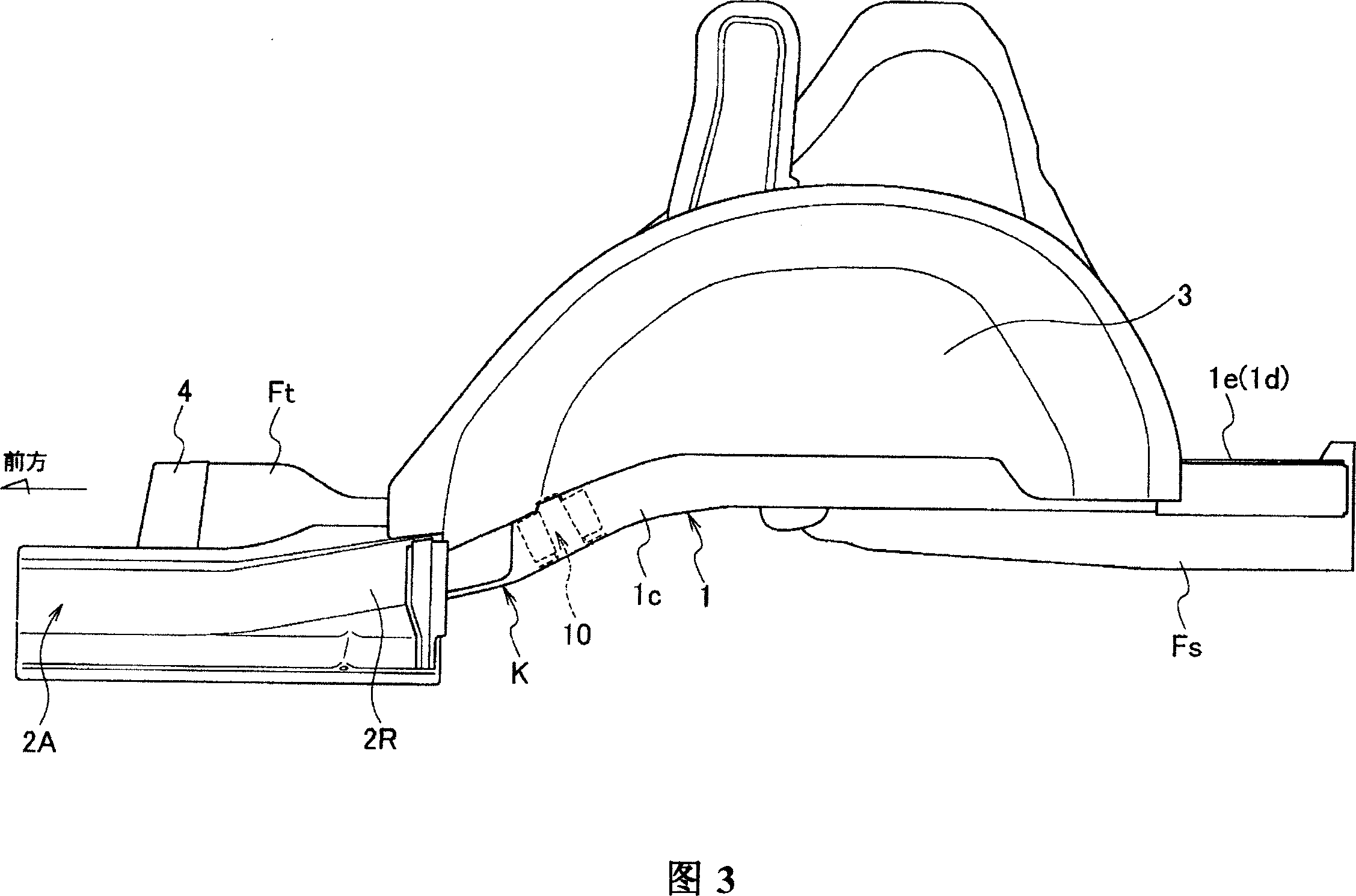

[0017] 1 to 6 show an embodiment of the rear structure of the vehicle body according to the present invention. FIG. 1 is a perspective view of the frame structure of the rear part of the vehicle body. FIG. Fig. 1 is a view viewed from the direction A, Fig. 4 is an enlarged oblique view showing the main part of the arrangement of the reinforcing member, Fig. 5 is an enlarged cross-sectional view along the line B-B in Fig. Oblique view of the reinforcement.

[0018] The structure of the rear part of the vehicle body in this embodiment is shown in Figures 1 and 2. On both sides in the vehicle width direction of the rear part of the vehicle body, a pair of left and right rear side beams 1 extending in the front and rear direction of the vehicle are provided. , the front part 1F is joined to the rear part 2R of the side sill inner side 2A, and extends from the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com