Closing method and apparatus

A technology of overturning device and pressure cover, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as rising working temperature, low quality assurance ability, and declining dynamic quality of bearings, so as to achieve reliable guarantee of finished product precision, shaft The effect of true and accurate clearance and accurate grease injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

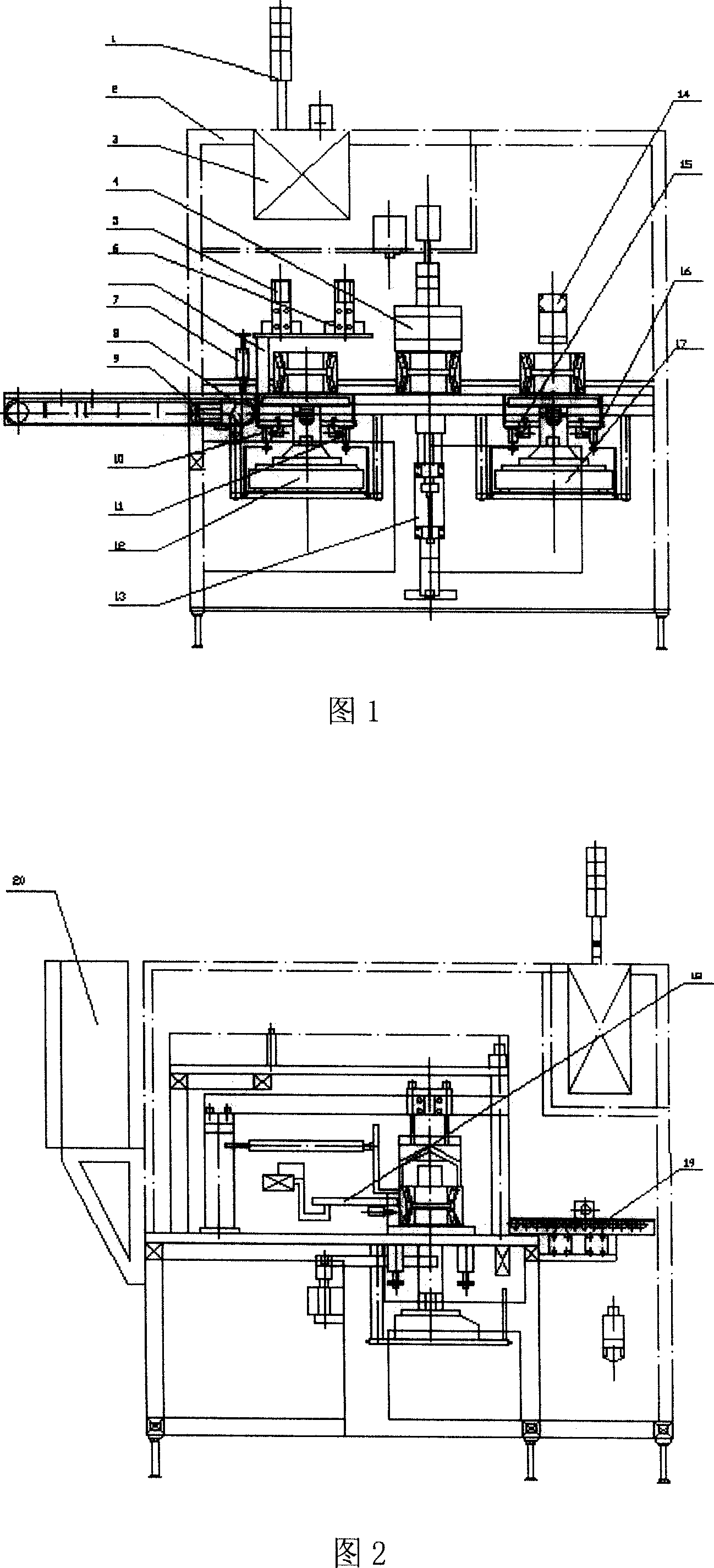

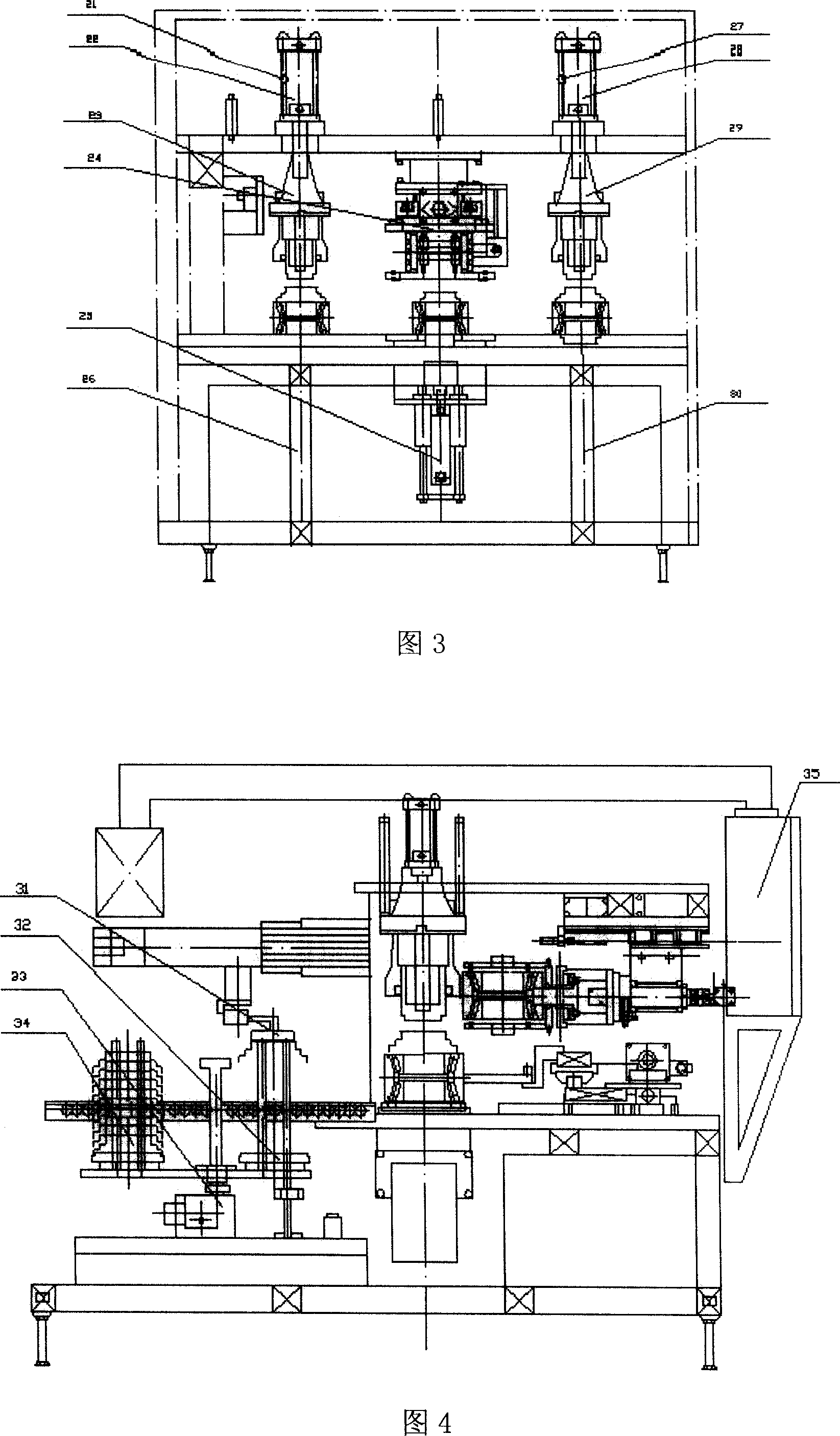

[0015] The present invention consists of indicator light 1, bed body 2, display screen 3, grease injection head 4, grease injection pump 5, grease injection pump 6, inlet stopper 7, chain plate 8, motor 9, cylinder 10, cylinder 11, electronic Scale 12, Cylinder 13, Ejector 14, Cylinder 15, Cylinder 16, Electronic Scale 17, Pusher 18, Unqualified Grease Injection Quantity Exiting Material Channel 19, Power Distribution Cabinet 20, Adjusting Device 21, Pressure Cover Cylinder 22, Pressure Cover Head 23, turning device 24, lifting cylinder 25, supporting platform 26, adjusting device 27, pressing cover cylinder 28, pressing cover head 29, supporting platform 30, manipulator 31, lifting device 32, rotating device 33, sealing cover storage area 34, The power distribution cabinet 35 is composed of; the pressure cover device is composed of two pressure cover cylinders, two pressure cover heads, a pusher, a turning device, a lifting cylinder and two manipulators;

[0016] Press cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com