Virtual machine real electric emulate system for assembling large industrial machinery

A large-scale machinery and simulation system technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve the problem of failure to obtain results, large-scale mechanical equipment installation and commissioning time-consuming, manpower, material resources, financial resources, and inconvenience And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

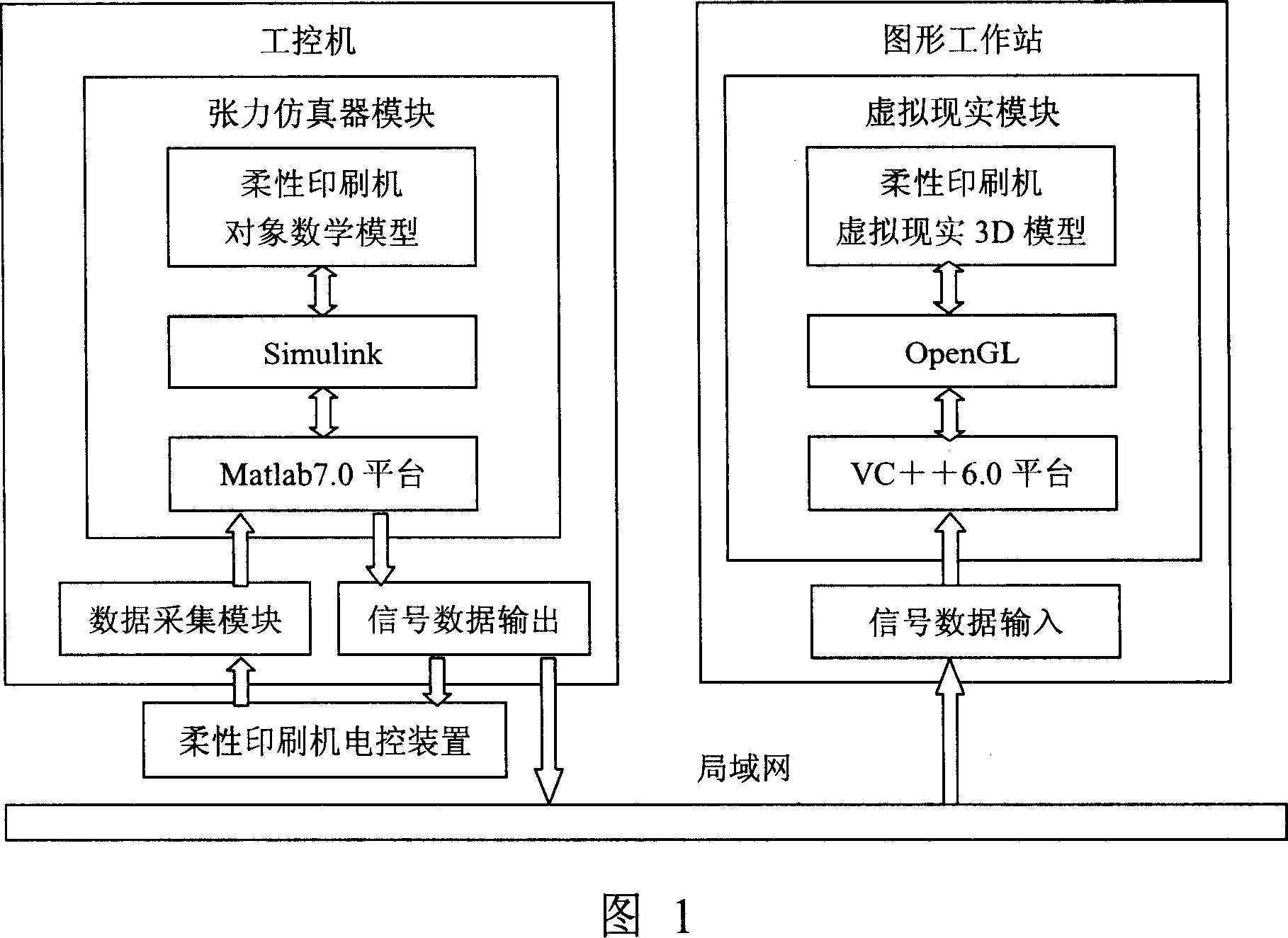

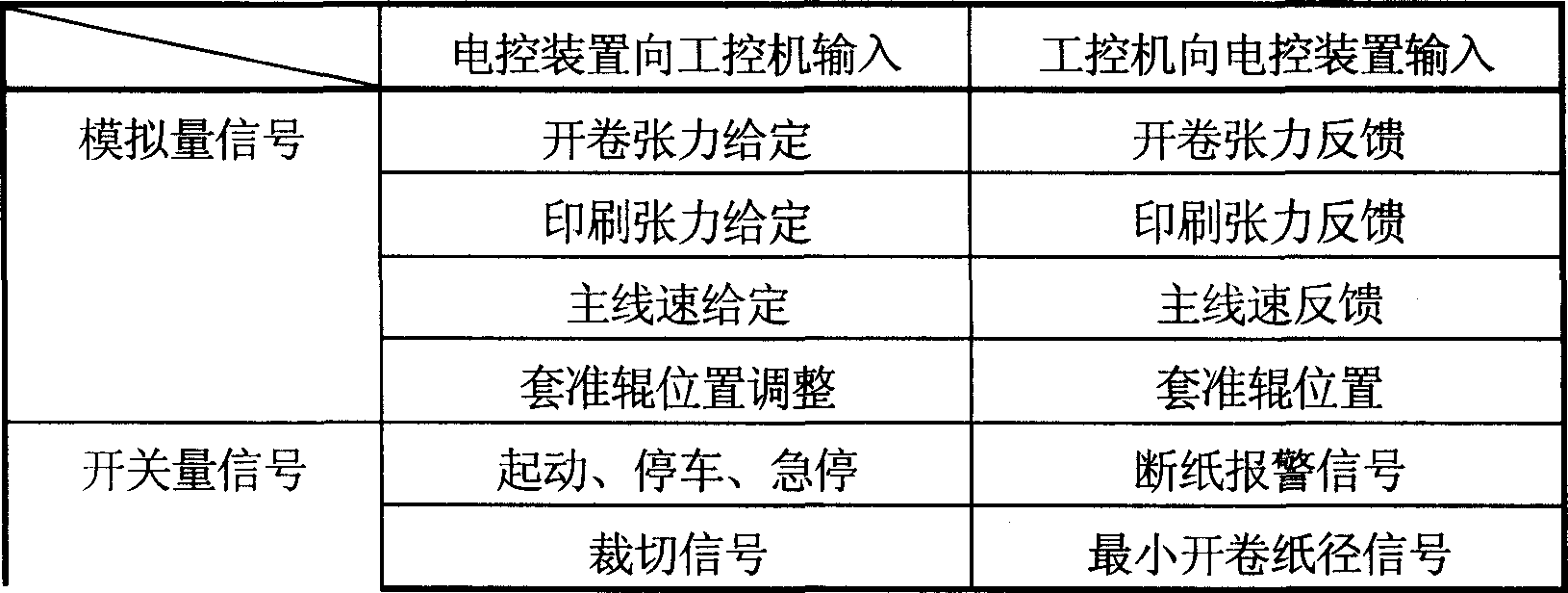

[0015] As an application example of the present invention, the virtual machine real-electricity simulation system of the flexible printing machine is introduced below. Data transmission and control between the control device module, the tension simulator module and the virtual reality module. The real-time control of the virtual printing machine by the real electronic control device is realized through experiments, and the correctness of the idea of the present invention is verified.

[0016] Virtual Machine Real Electric Simulation System for Flexible Printing Machine

[0017] 1. Brief introduction of flexible printing machine

[0018] The flexographic printing machine is a typical unit-type web printing machine, which is divided into four functional units: unwinding, printing, sheet cutting and conveying table. Configure different numbers of functional units according to different printing process requirements. Shown is a standard four-color flexo press configuration. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com