Conveyance apparatus with lifting/lowering load carrying platform

A conveying device and racking technology, which is applied in the direction of lifting frame, lifting device, manual conveying device, etc., can solve the problems such as the design of the walking body that cannot be transported, the inability to lower the top surface, and the increase in height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

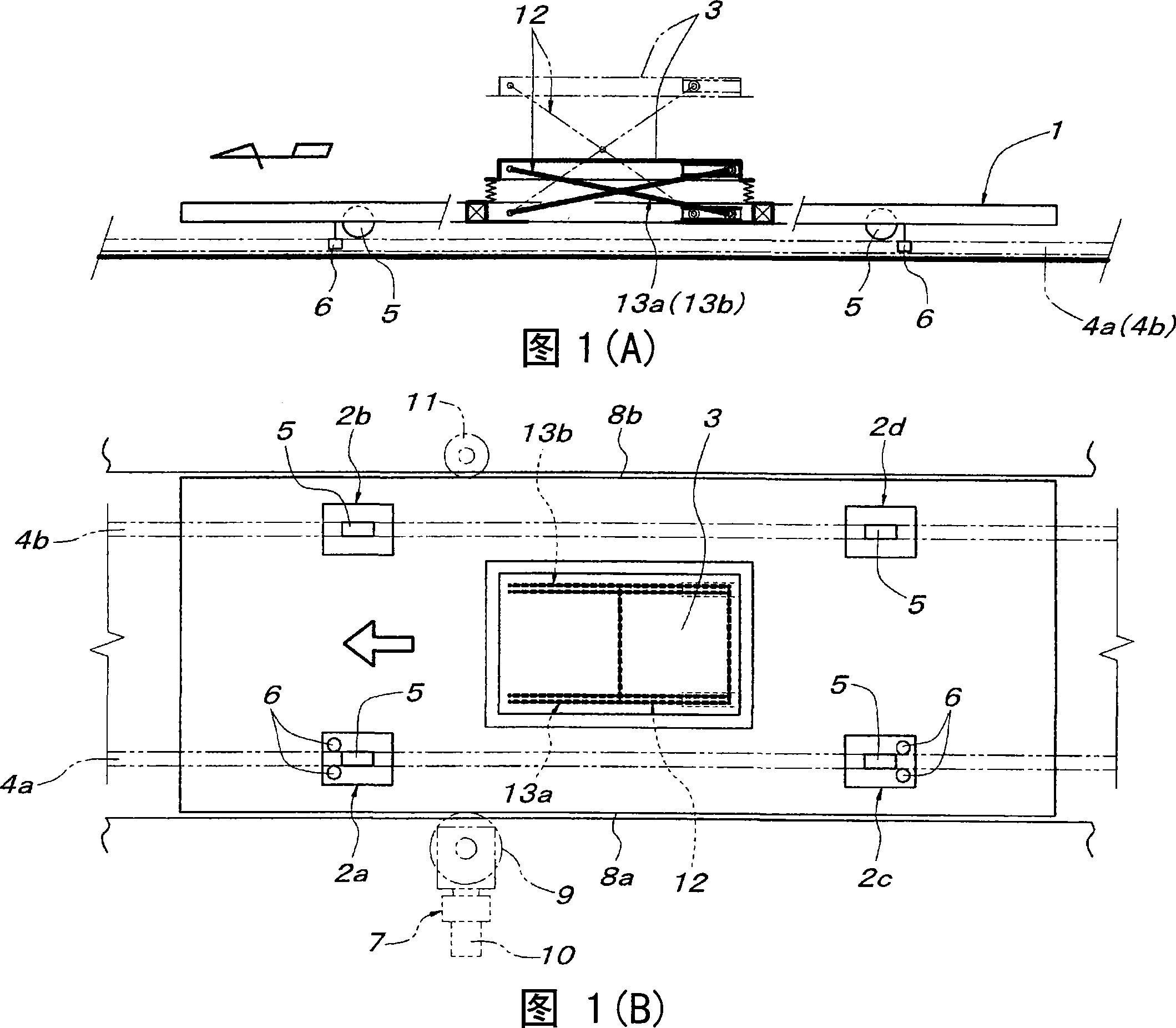

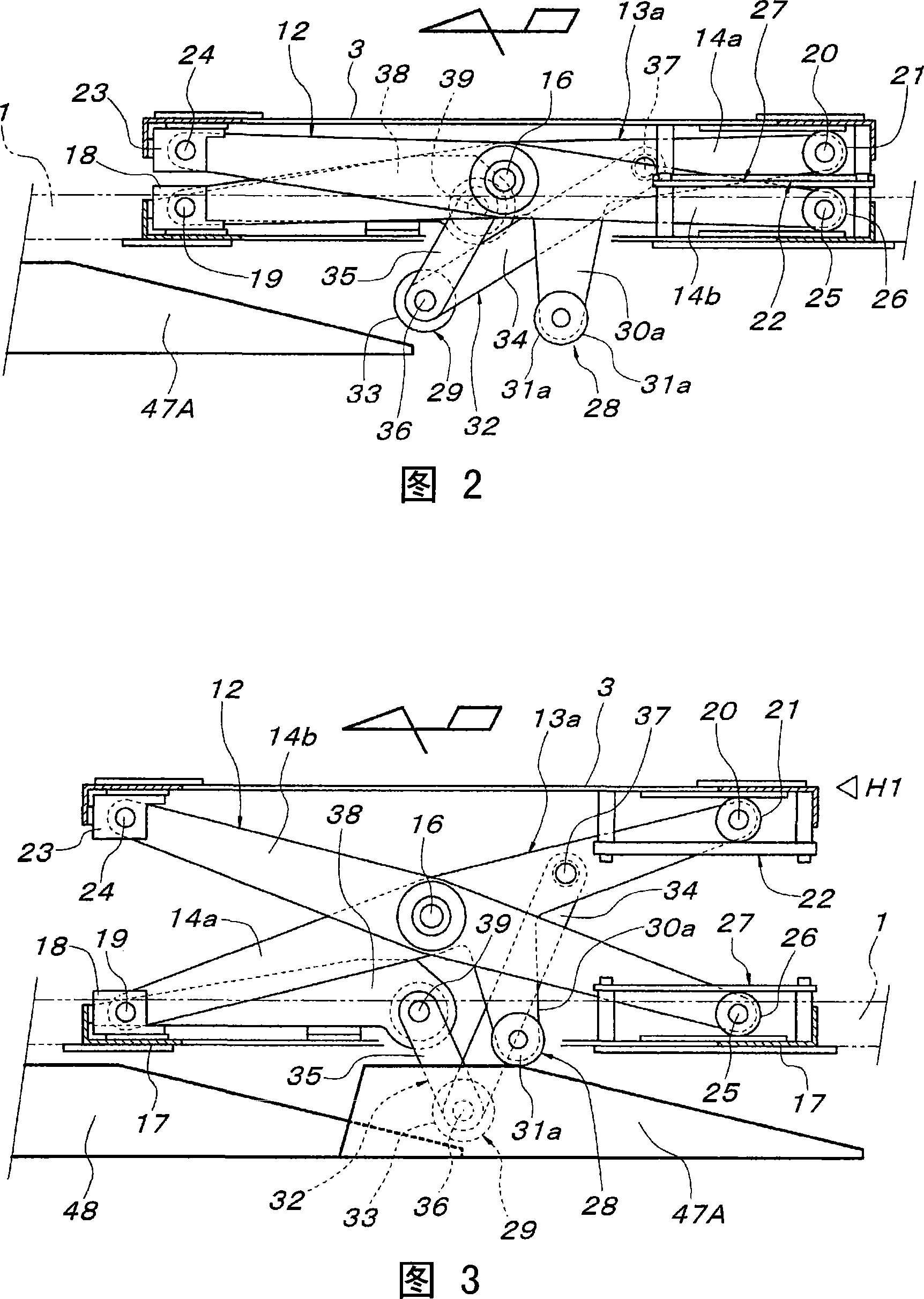

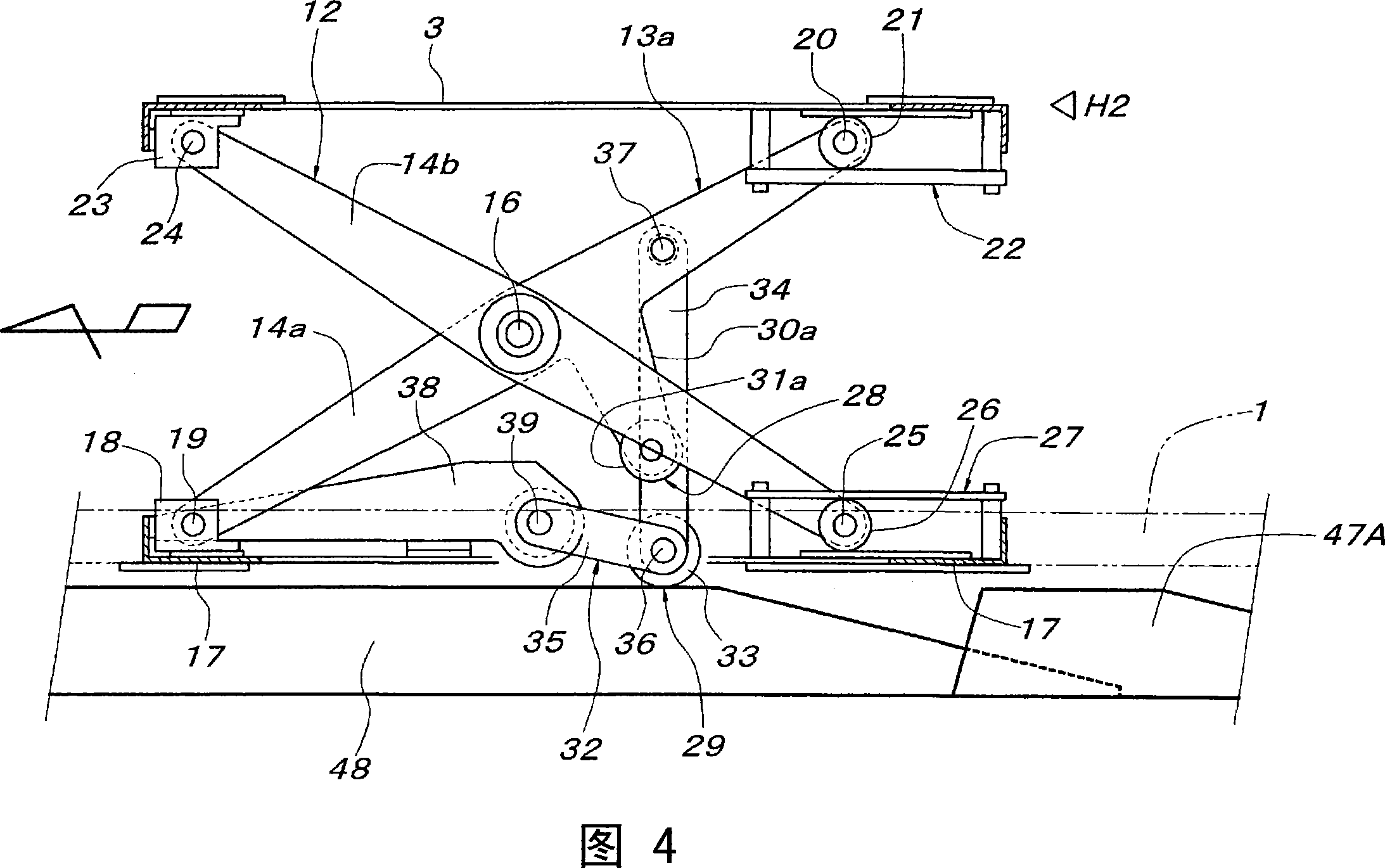

[0023] Below, specific embodiments of the present invention will be described according to the accompanying drawings. Fig. 1 shows the basic structure of a transport device with a friction-driven form of a shelf that can be lifted. The walking body for transportation has a left and right pair of front and rear wheel assemblies 2a-2d and a liftable shelf 3. Each wheel unit 2a-2d has a wheel 5 rolling on a pair of left and right guide rails 4a, 4b laid along the transport path, and is provided on the front and rear two wheel units 2a, 2c on the left and right sides (the left side in the illustration). There are vibration-proof vertical axis rollers 6 sandwiching the guide rail 4a from both left and right sides. The traveling body 1 for transportation is propelled by a friction drive mechanism 7 provided at an appropriate point in the transportation path. The friction drive mechanism 7 is a conventionally known technology, and it is composed of a drive friction wheel 9, a motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com