Universal tapper

A hole opener and jack technology, which is applied in metal processing, fluid pressure actuating devices, etc., can solve the problems of hose detachment, inconvenience in use, breakage, etc., and achieves easy change, simple structure, and oil circuit tightness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

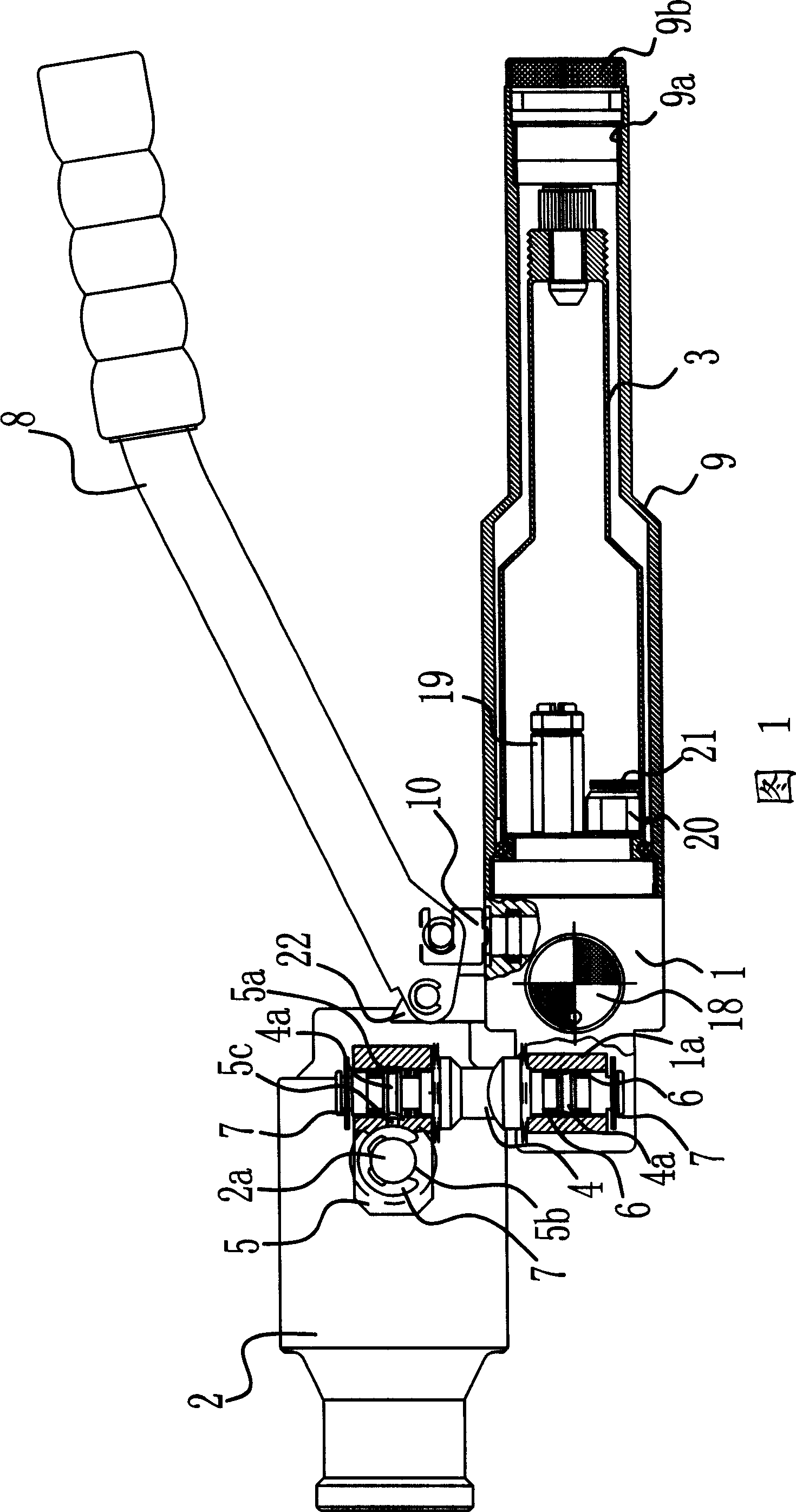

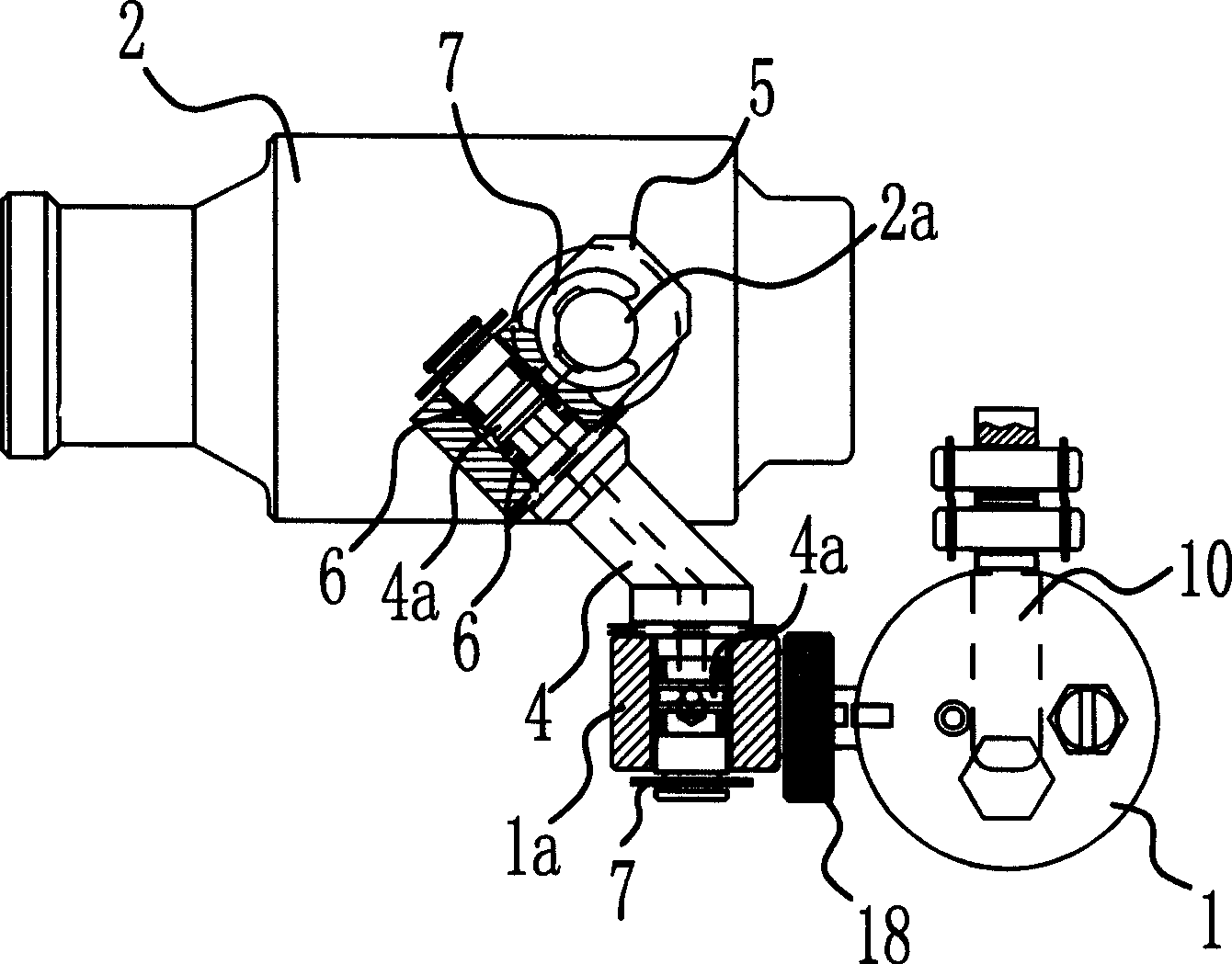

[0022] Such as figure 1 As shown, this universal hole opener is made up of parts such as oil pump body 1, oil cylinder 2, oil storage chamber 3, connecting pipe 4, double-hole joint 5, movable handle 8, fixed handle 9. The piston rod of the oil cylinder 2 is fixedly connected with a male mold for opening holes, and the male mold can cooperate with the female mold to realize the drilling of workpieces or metal plates.

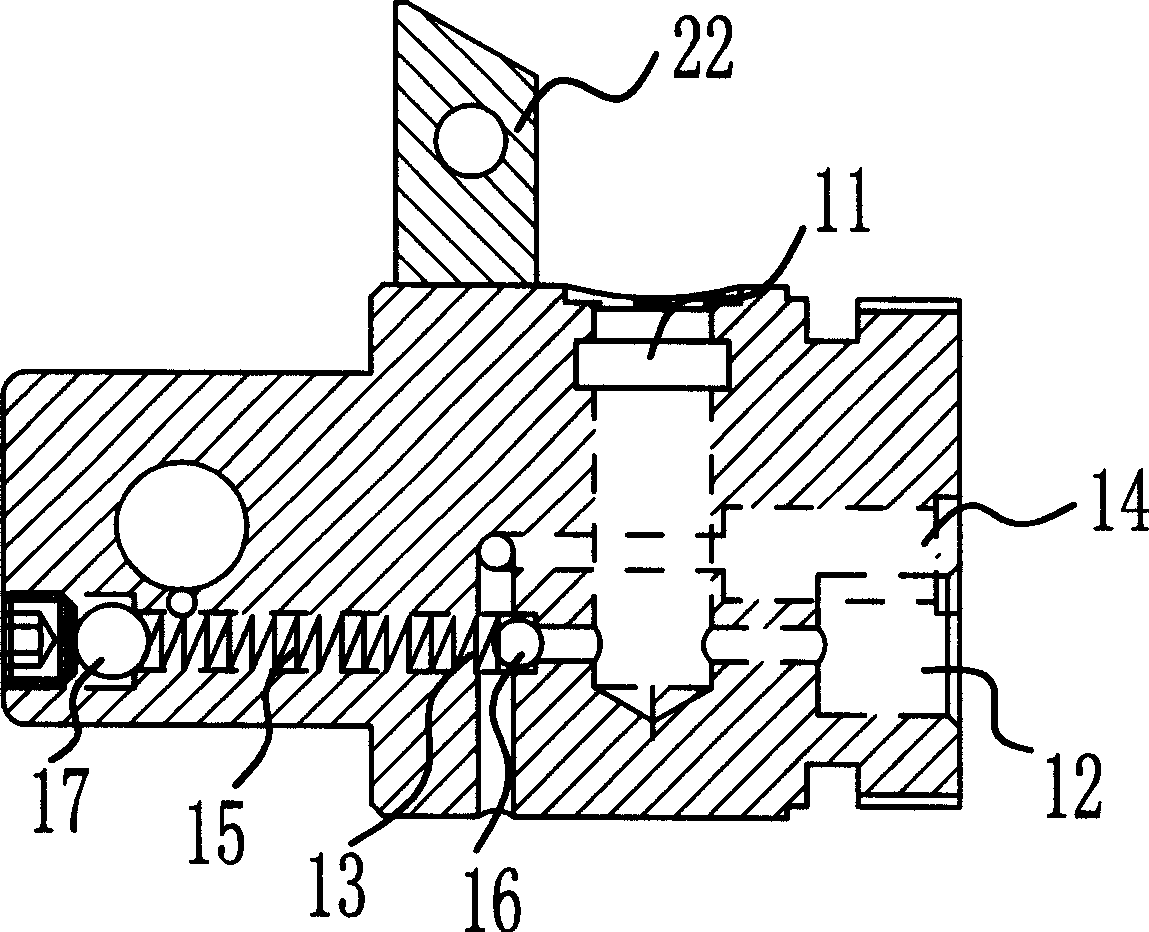

[0023] Such as figure 1 with figure 2 As shown, the oil pump body 1 is respectively connected with the oil cylinder 2 and the oil storage chamber 3 through the oil passage. Between the oil cylinder 2 and the oil pump body 1 is provided a rigid movable coupling mechanism for connecting the two oil passages. The movable connection mechanism includes a curved connecting pipe 4, one end of the connecting pipe 4 is hinged with the oil outlet bolt 1a of the oil pump body 1, the other end is hinged with the socket 1 5a of the double-hole joint 5, and the socket 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com