Relatively low viscosity transmission fluids

A transmission fluid, low viscosity technology, applied in the field of transmission applications, can solve the problems of anti-wear and extreme pressure characteristics, and achieve the effect of good steel-steel friction and excellent friction durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

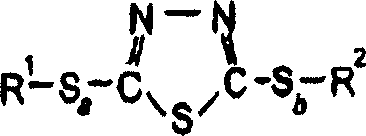

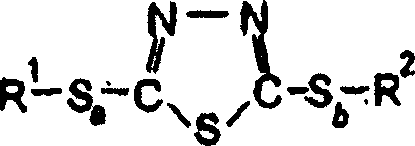

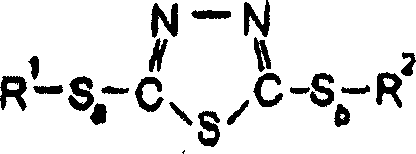

Image

Examples

Embodiment Construction

[0040] As used herein, the term "hydrocarbyl substituent" or "hydrocarbyl" is used in its ordinary meaning, which is well known to those skilled in the art. Specifically, it refers to a group having a carbon atom directly attached to the rest of the molecule and having a predominantly hydrocarbon character. Examples of hydrocarbyl groups include:

[0041] (1) Hydrocarbon substituents, that is, aliphatic substituents (such as alkyl or alkenyl), cycloaliphatic substituents (such as cycloalkyl, cycloalkenyl); and aromatic-, aliphatic- and cycloaliphatic Substituted aromatic substituents, and cyclic substituents, where the ring is closed by another part of the molecule (eg, two substituents together form a cycloaliphatic group);

[0042] (2) Substituted hydrocarbon substituents, i.e. substituents comprising non-hydrocarbon groups which, in the context of this specification, do not alter the predominant hydrocarbon substituents such as halogen (especially chlorine and fluorine), h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com