Fixing time detecting method for roller compacted concrete construction site

A roller compacted concrete, construction site technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve problems such as inconvenient, indirect coverage time, and non-targeted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

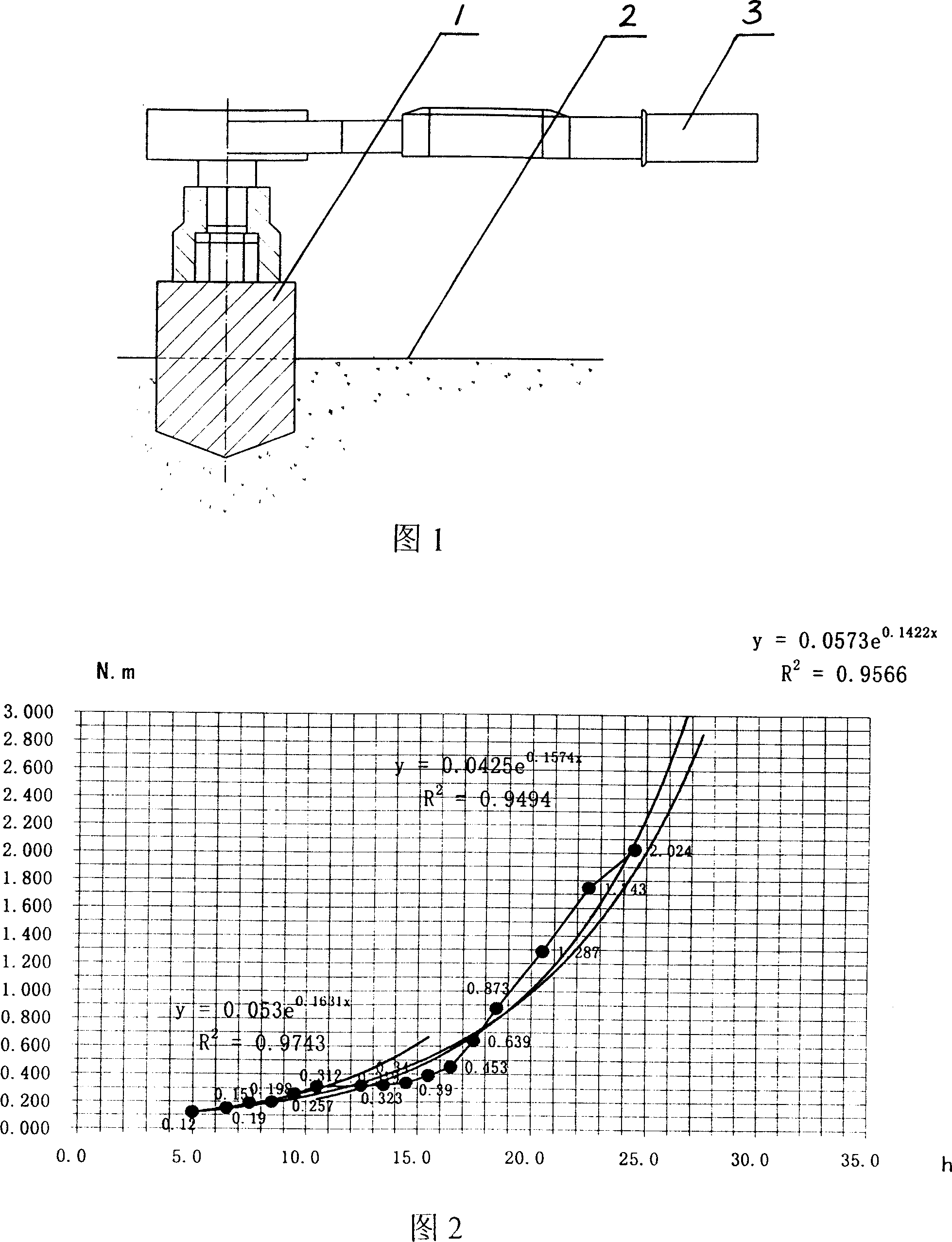

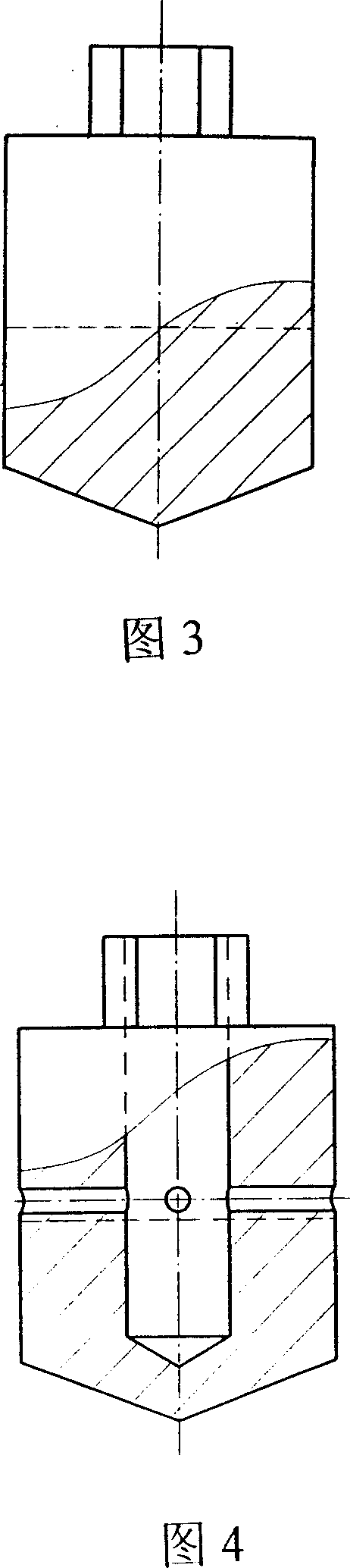

[0023] Embodiment 1: The method for detecting the setting time of the roller compacted concrete construction site, taking the dam roller compacted concrete construction as an example, implements according to the following steps:

[0024] (1) On the concrete surface 2 that has been paved and rolled, the probe 1 is embedded downward. The probe 1 is a cone with a cylindrical shape, the cylindrical surface is engraved with an embedded depth line, and the bottom is easy to be embedded. Common probe made of metal material with hexagonal nut on the shape and top, the outer diameter of probe 1 is 30mm;

[0025] (2), record the time of adding water to the mixed concrete as the detection start time;

[0026] (3), according to the set time interval, use the rotational moment detector 3 to measure the rotational moment value of the probe in the conventional way, the interval time is 15min, if the retarder is applied in the concrete, the interval time is 30min;

[0027] (4), probe detecti...

Embodiment 2

[0031] Embodiment 2: the method for detecting the setting time of the roller compacted concrete construction site, still take the dam roller compacted concrete construction as an example, and implement according to the following steps:

[0032] (1) On the concrete surface 2 that has been paved and rolled, the probe 1 is embedded downward. The probe (1) is cylindrical, with an embedded depth line engraved on the cylindrical surface, and the bottom is convenient for insertion A bleeding-type probe with a conical shape and a hexagonal nut on the top made of non-metallic material, the body is provided with a bleeding groove, and a bleeding-water collection hole is arranged on the depth line, and the outer diameter of the probe (1) is 50mm;

[0033] Steps (2) to (4) are the same as steps (2) to (4) of Example 1;

[0034] (5), probe detection. The probe detects more than 3 times per unit detection time, and then determines the value of the obtained rotation torque value according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com