Substrate processing apparatus

A substrate processing device and a substrate technology, which are applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problem of reduced operating rate of the substrate processing device 200, increased consumption and discharge of processing liquid, and reduced processing performance of the processing liquid To achieve the effect of improving the operating rate, maintaining the processing performance, and reducing the amount of liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0060]

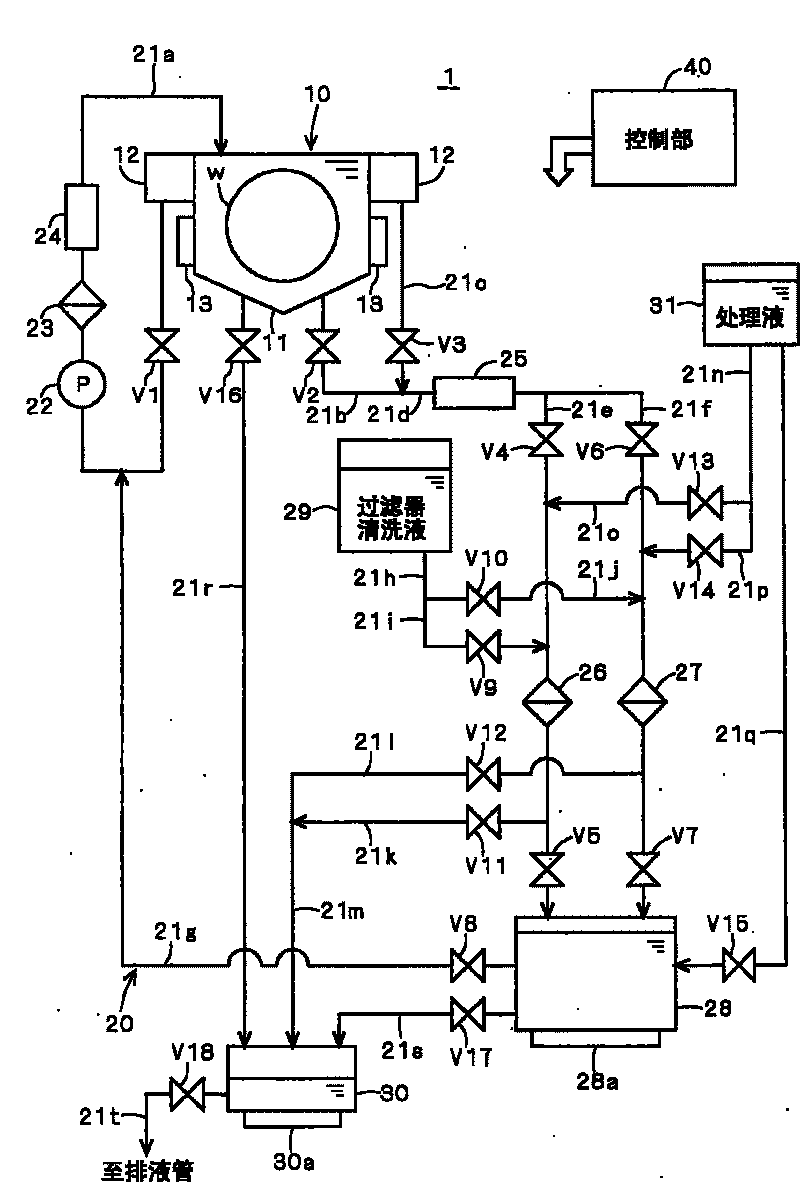

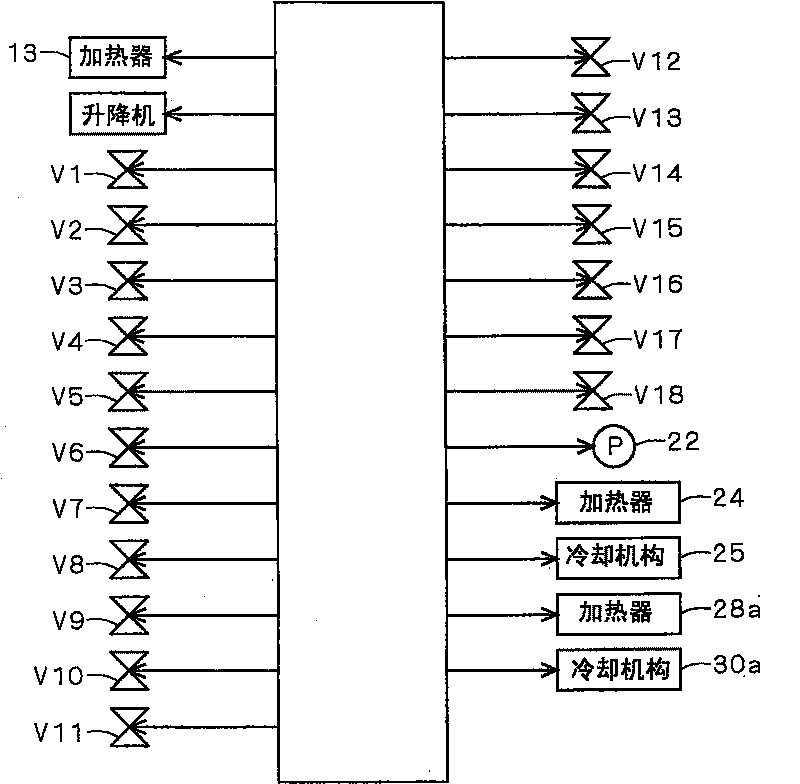

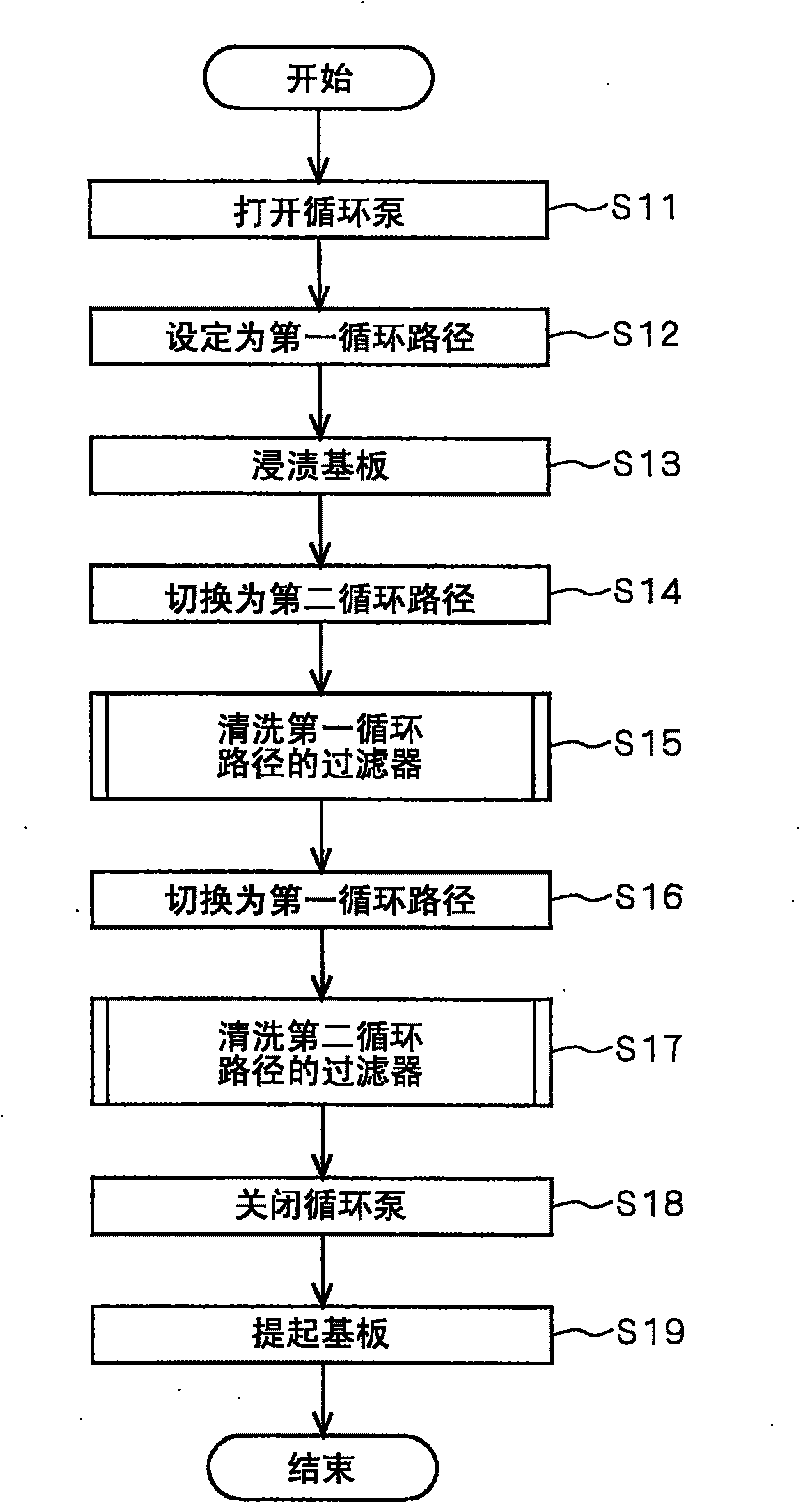

[0061] figure 1 It is a figure which shows the structure of the substrate processing apparatus 1 which concerns on one Embodiment of this invention. This substrate processing apparatus 1 is an apparatus for processing a substrate W by immersing a plurality of substrates (hereinafter simply referred to as substrates) W in a processing liquid stored in a processing tank 10 . The substrate processing apparatus 1 mainly includes a processing tank 10 , a piping unit 20 , and a control unit 40 . In this embodiment, for the use of phosphoric acid (H 3 PO 4 ) solution as a treatment solution for etching the surface of the substrate W will be described.

[0062] The processing tank 10 is a container for storing a processing liquid. The processing tank 10 has an inner tank 11 for immersing the substrate W, and an outer tank 12 provided on the outer surface of the inner tank 11 . The treatment liquid supplied to the inner tank 11 is stored inside the inner tank 11 and ov...

no. 2 approach

[0123]

[0124] Figure 6 It is a figure which shows the structure of the substrate processing apparatus 101 which concerns on 2nd Embodiment of this invention. This substrate processing apparatus 101 is an apparatus for processing a substrate W by immersing a plurality of substrates (hereinafter simply referred to as substrates) W in a processing liquid stored in a processing tank 110 . The substrate processing apparatus 101 mainly includes a processing tank 110 , a piping unit 120 , and a control unit 140 . In this embodiment, for the use of phosphoric acid (H 3 PO 4 ) solution is used as the treatment liquid to perform etching treatment on the surface of the substrate W will be described.

[0125] The processing tank 110 is a container for storing a processing liquid. The processing tank 110 has an inner tank 111 for dipping the substrate W, and an outer tank 112 provided at the upper end of the outer surface of the inner tank 111 . The treatment liquid supplied to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com