Method for real-time evaluating internal-external temperature difference of nickel-hydrogen electrokinetic cell

A technology of internal and external temperature difference, power battery, applied in nickel battery, secondary battery, alkaline battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

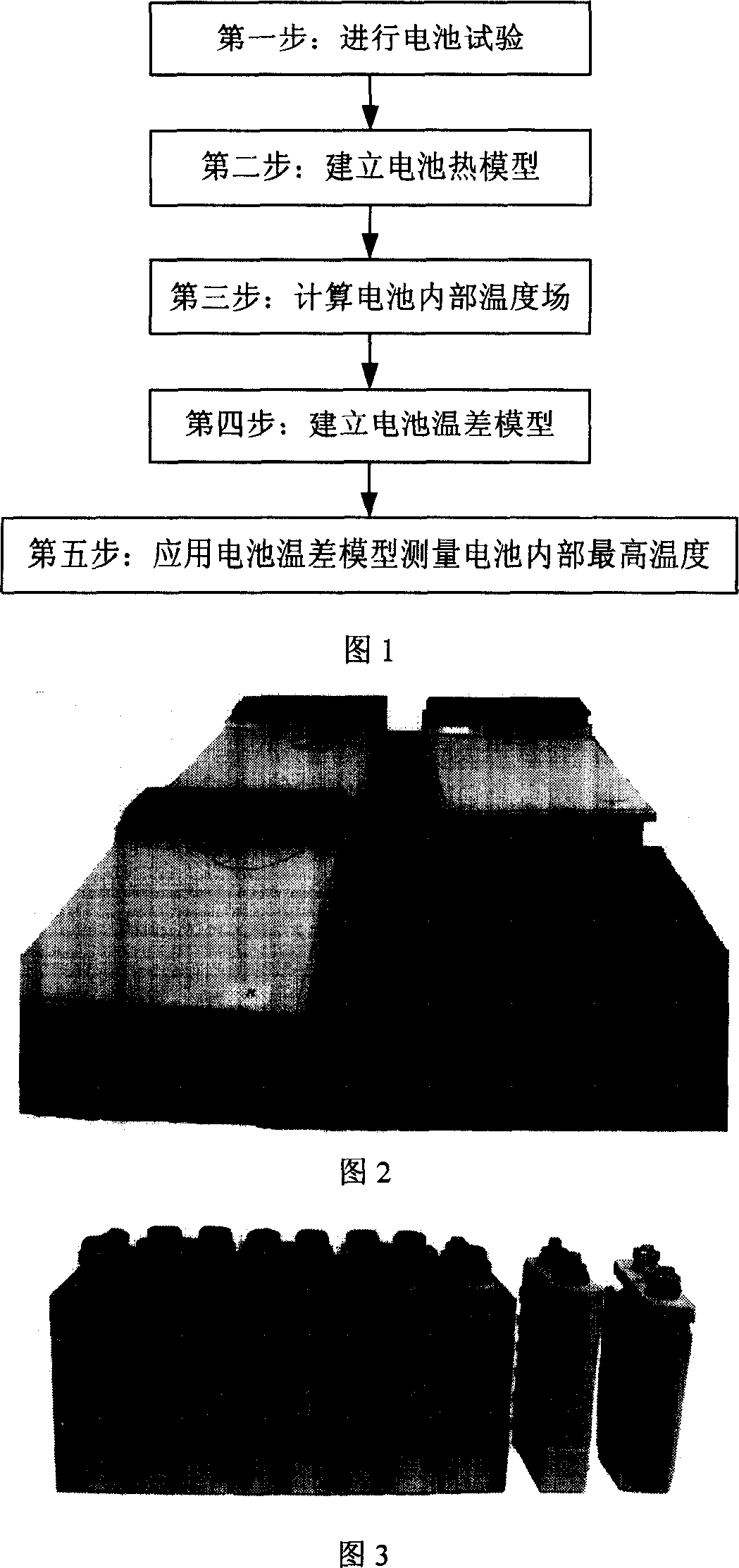

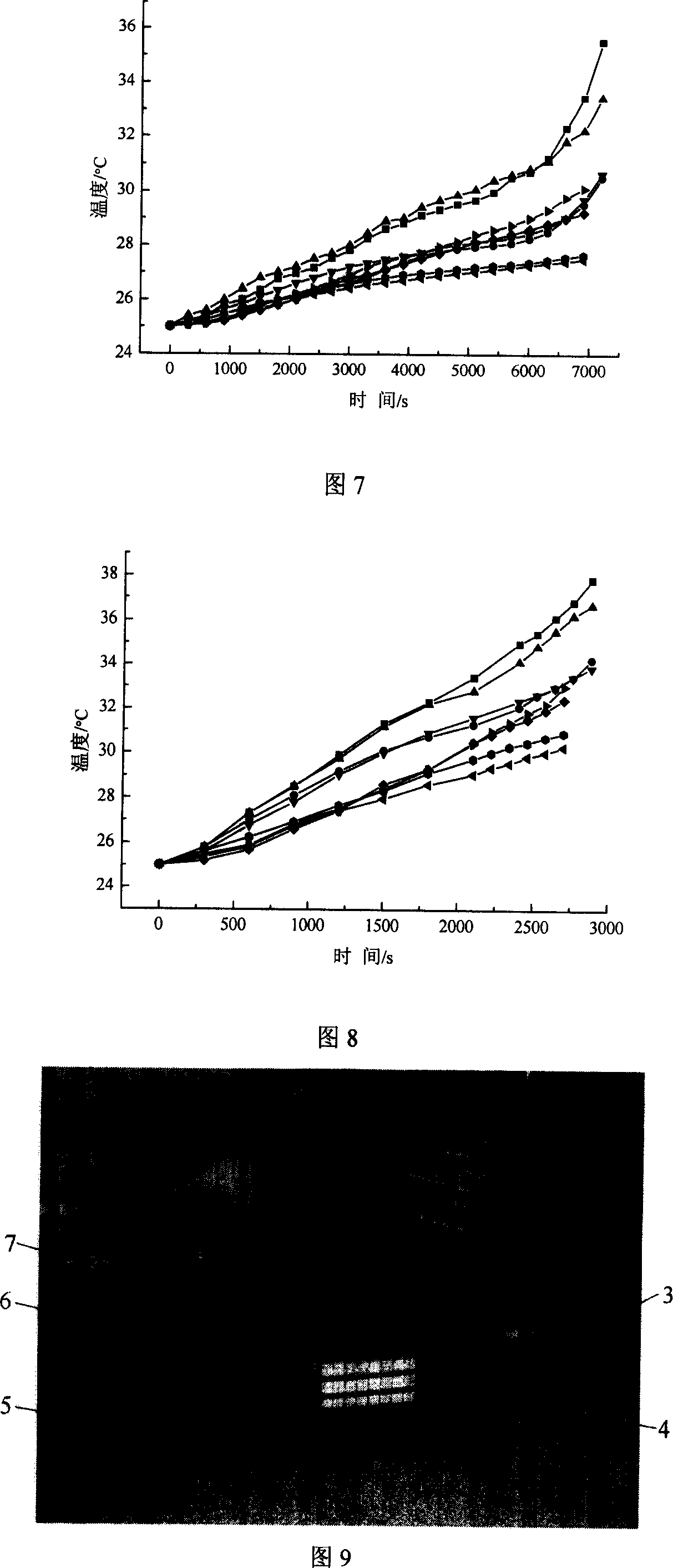

[0078]Taking a nickel-metal hydride battery pack with a rated capacity of 80Ah, which is composed of 320 cells in series, as an example, the implementation process of the method for real-time estimation of the temperature difference between the inside and outside of the electric vehicle power battery is introduced. Figure 2 shows the Ni-MH battery pack, and Figure 3 shows the battery modules and battery cells in the battery pack, and the rightmost battery cell in the figure is stripped of its casing. Figure 4 shows the process of utilizing the present invention to obtain the highest temperature inside the battery cell

[0079] The first step: conduct a battery test.

[0080] (1) Ni-MH battery heat generation characteristics test

[0081] The battery heat generation characteristic test is used to grasp the temperature change curve of the battery surface during the charging and discharging process of the battery, which is the basic basis for verifying the battery thermal model....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com