Polypropylene resin composition and process for producing the same

A polypropylene resin and composition technology, applied in the field of polypropylene resin composition and its preparation, can solve problems such as adverse effects on productivity, poor dispersion of inorganic fillers, etc., and achieve the effects of excellent appearance and improvement of flexural modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

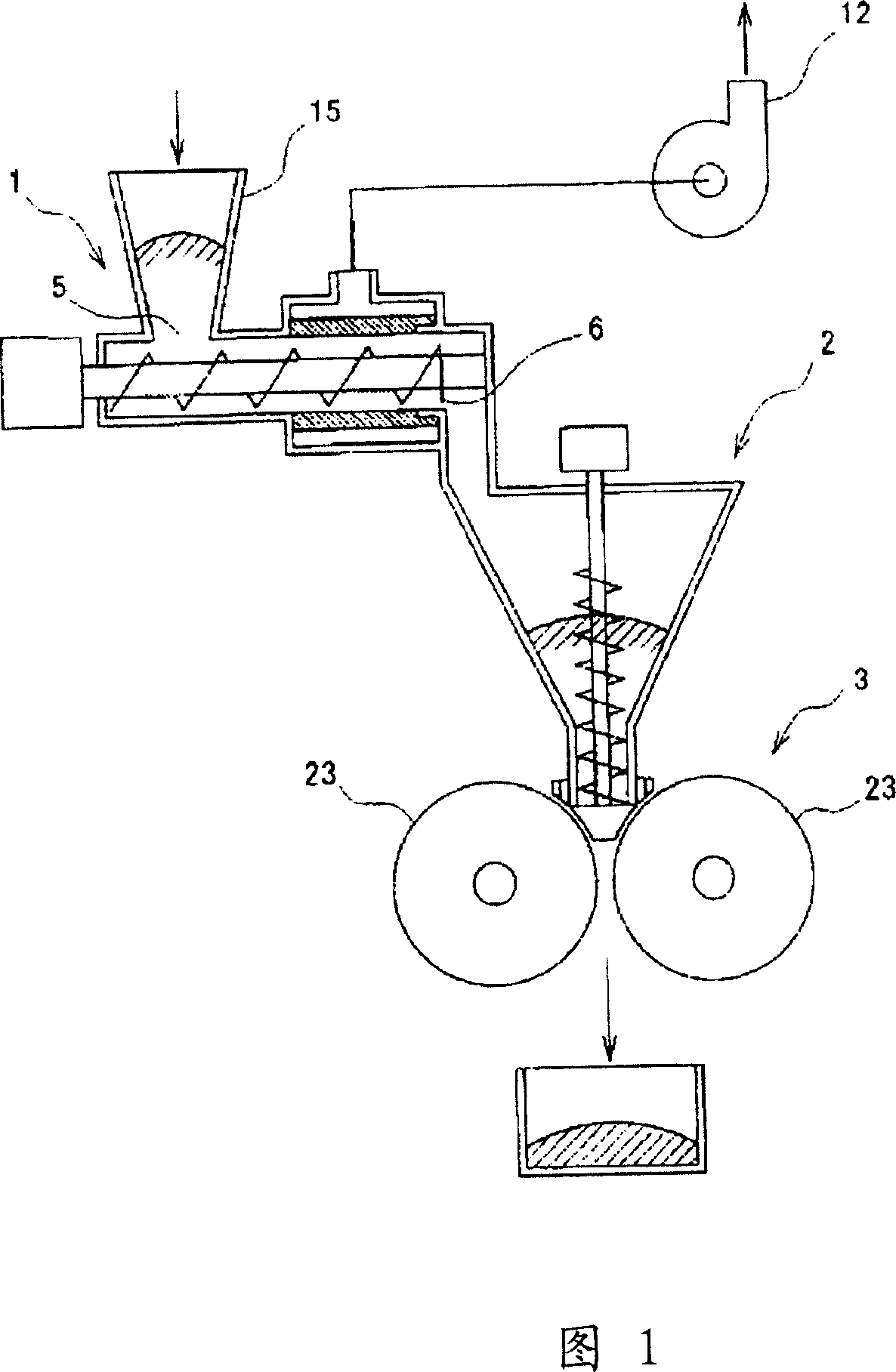

[0078] [II] Preparation method of talc-containing polypropylene resin composition

[0079] The method for producing the polypropylene resin composition of the present invention comprises supplying the above-mentioned polypropylene resin and the above-mentioned degassed compressed talc to an extruder installed downstream of a polymerization reactor for producing the above-mentioned polypropylene resin, and performing melt-kneading.

[0080] The talc-containing polypropylene resin composition of the present invention is prepared by melt-kneading with a large-scale kneader with a large extrusion capacity. At this time, in order to obtain the economic advantage of in-line mixing, it is preferable to perform the transfer, premixing, melt-kneading, and granulation steps consecutively from the polymerization step as described below.

[0081] First, the polypropylene resin prepared by the polypropylene polymerization equipment is transferred to the mixing and granulation equipment thr...

Embodiment 1

[0101] Microparticle talc (manufactured by Hayashi Kasei Co., Ltd.: MW5000S) with an average particle size of 5.0 μm and a volume specific gravity of 0.12 (manufactured by Hayashi Kasei Co., Ltd.: MW5000S) (hereinafter referred to as raw material 1) was degassed once using Klipak manufactured by Kurimoto Iron Works until the volume specific gravity reached 0.35. After that, without taking it out, it was compressed twice using a roller compactor manufactured by Kurimoto Iron Works (roller gap: 1.1mm, roller rotation speed: 10rpm, extrusion screw: 17rpm) to prepare degassed compressed talc (talc-1 ).

[0102] The properties of this talc-1 were that the volumetric specific gravity was 0.58, the amount of components larger than 1000 μm was 5.5% by weight, and the amount of components larger than 500 μm was 35.9% by weight as measured by the Rotap sieve method. In addition, the amount of components of 500 μm or more measured by the improved sieve method was 3.4% by weight, which is...

Embodiment 2

[0107]In Example 1, except that polypropylene homopolymer (PP-2: MFR=6g / 10 minutes, produced by Japan Polypro (KK) Co., Ltd., product name MA4CQ) was used instead of PP-1, it was completely the same as in Example 1. The experimental conditions were melt-kneaded to prepare a polypropylene resin composition. The obtained pellets were subjected to injection molding and evaluated for white spots. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com