Printing device capable of adjusting output resolution ratio

A technology of printing equipment and resolution, applied in the field of printing, can solve the problems of plastic grating scale vibration, insufficient stability, and failure to meet precision requirements, etc., and achieve the effect of high reliability and high printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

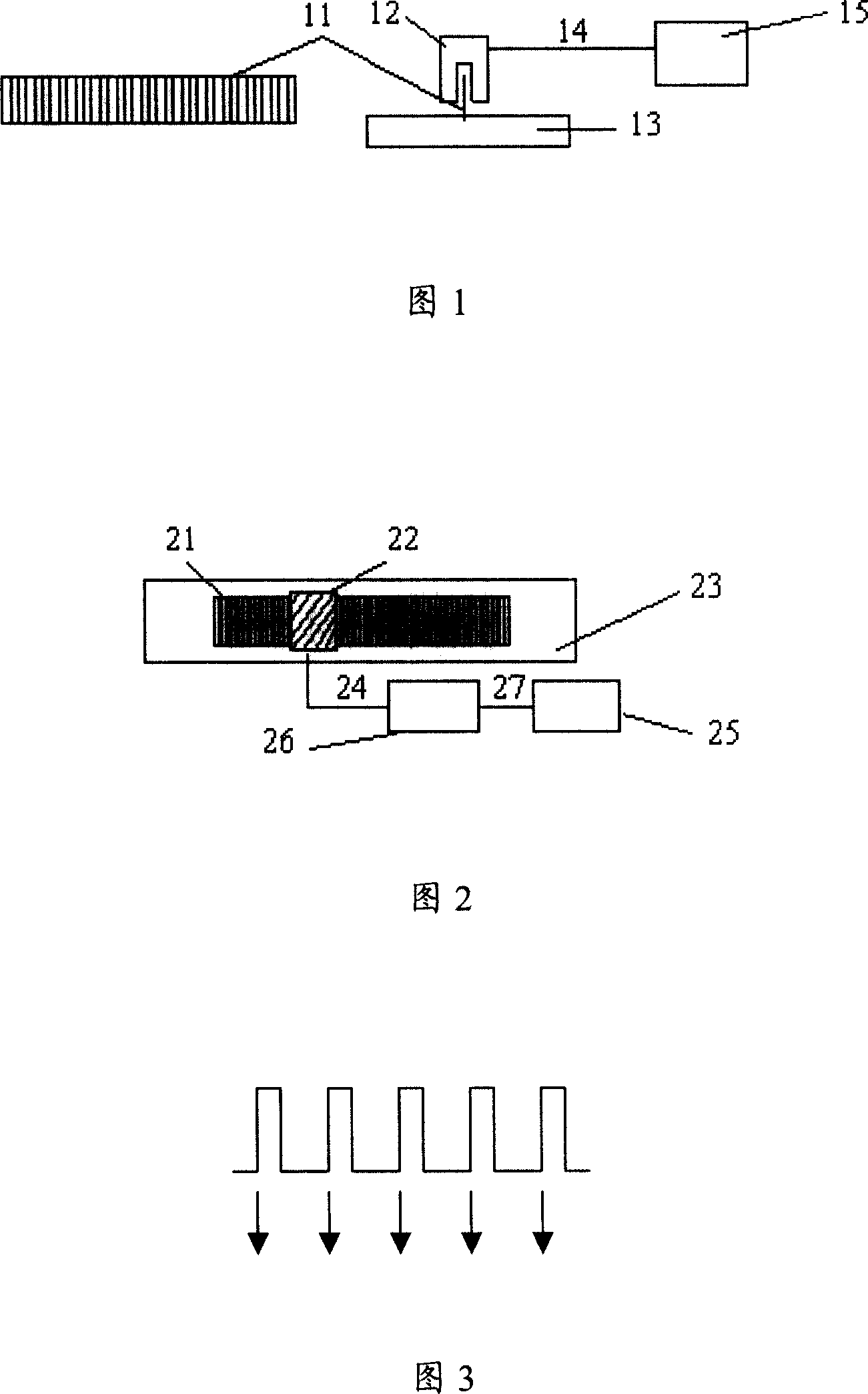

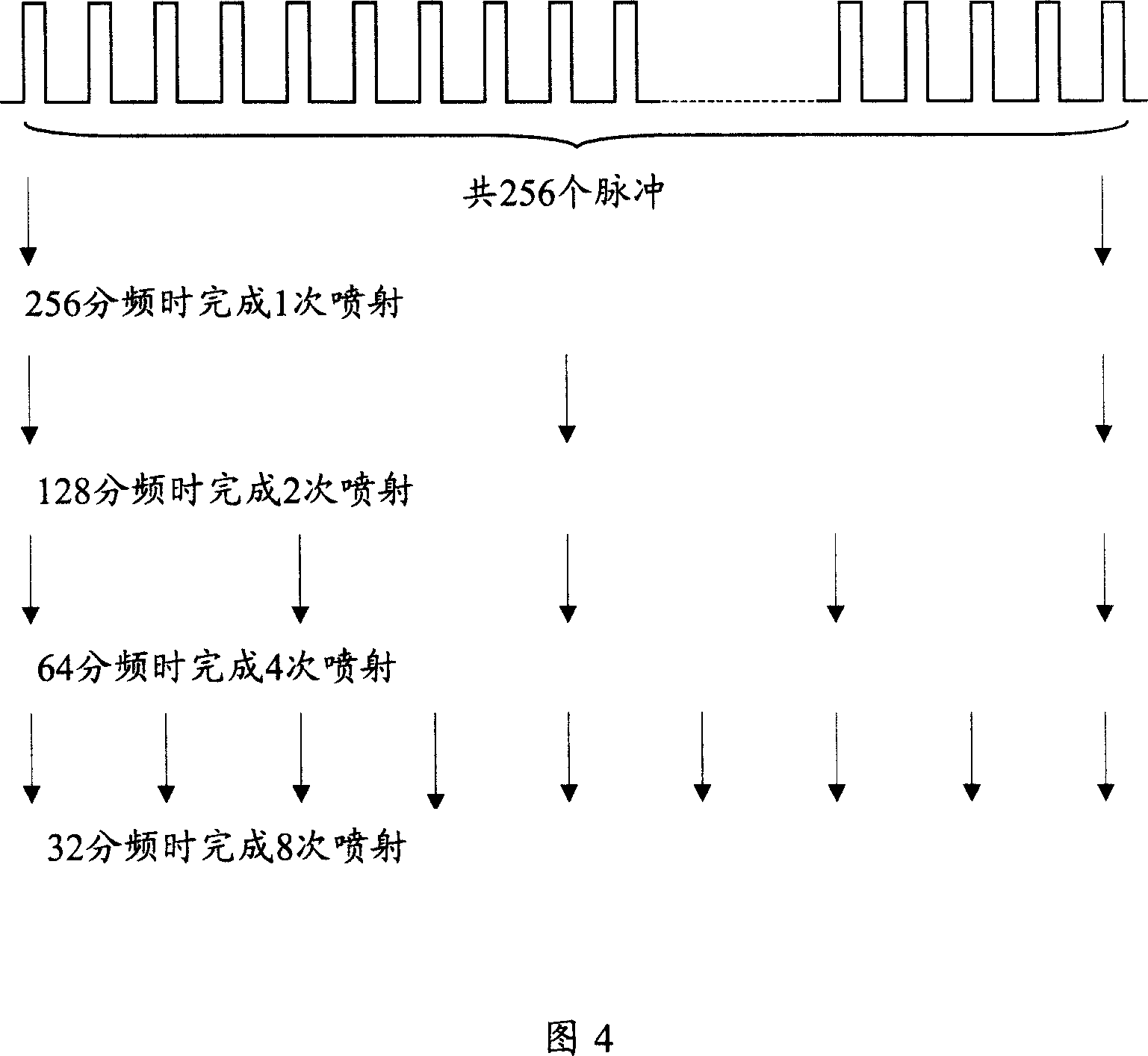

[0029] Embodiment 1, a printing device with adjustable output resolution, this printing device includes a metal grating scale 21 , a reading head 22 , a frame 23 , wires 24 , wires 27 , a decoder 25 and an adjustable frequency divider 26 . Figure 2 is a schematic diagram of the installation structure of the device. In FIG. 2 , one plane of the metal grating ruler 21 is close to the frame 23 and fixed on the frame 23 , and the read head 22 is located on the other side of the metal grating ruler 21 opposite to the frame 23 . The signal read by the reading head 22 is output to the adjustable frequency divider 26 through the wire 24, and the adjustable frequency divider 26 divides the input signal according to the frequency division factor selected by the user, and then outputs it to the decoder 25 through the wire 27 , the decoder 25 decodes and outputs the signal output by the adjustable frequency divider 26 . Each time a decoding pulse is output, the nozzle completes one injec...

Embodiment 2

[0036] Embodiment 2, a printing device with adjustable output resolution. The difference from Embodiment 1 is that the printing device also includes a frequency multiplier, which is used to multiply the frequency of the signal output by the decoder before outputting. The frequency multiplication coefficient Can be 2 or 4. For example, when the frequency multiplication factor is 2, the precision of the metal grating scale used is still set to 1um, and the corresponding output resolution after 100 frequency division decoding at this precision is 254dpi, then after 2 frequency multiplication, the actual output resolution is 254dpi*2=508dpi, after 4 frequency multiplication, the actual output resolution is 254dpi*4=1016dpi, similarly, after 200 frequency division and 2 frequency multiplication, the output resolution is 127dpi*2=254dpi,...256 frequency division and then 2 The output resolution after frequency doubling is 99dpi*2=198dpi, so the continuously adjustable range of outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com