Composite engine speed control

一种速度控制、控制元件的技术,应用在发动机控制、机器/发动机、调速器等方向,能够解决成本增加、零件总数和存货增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

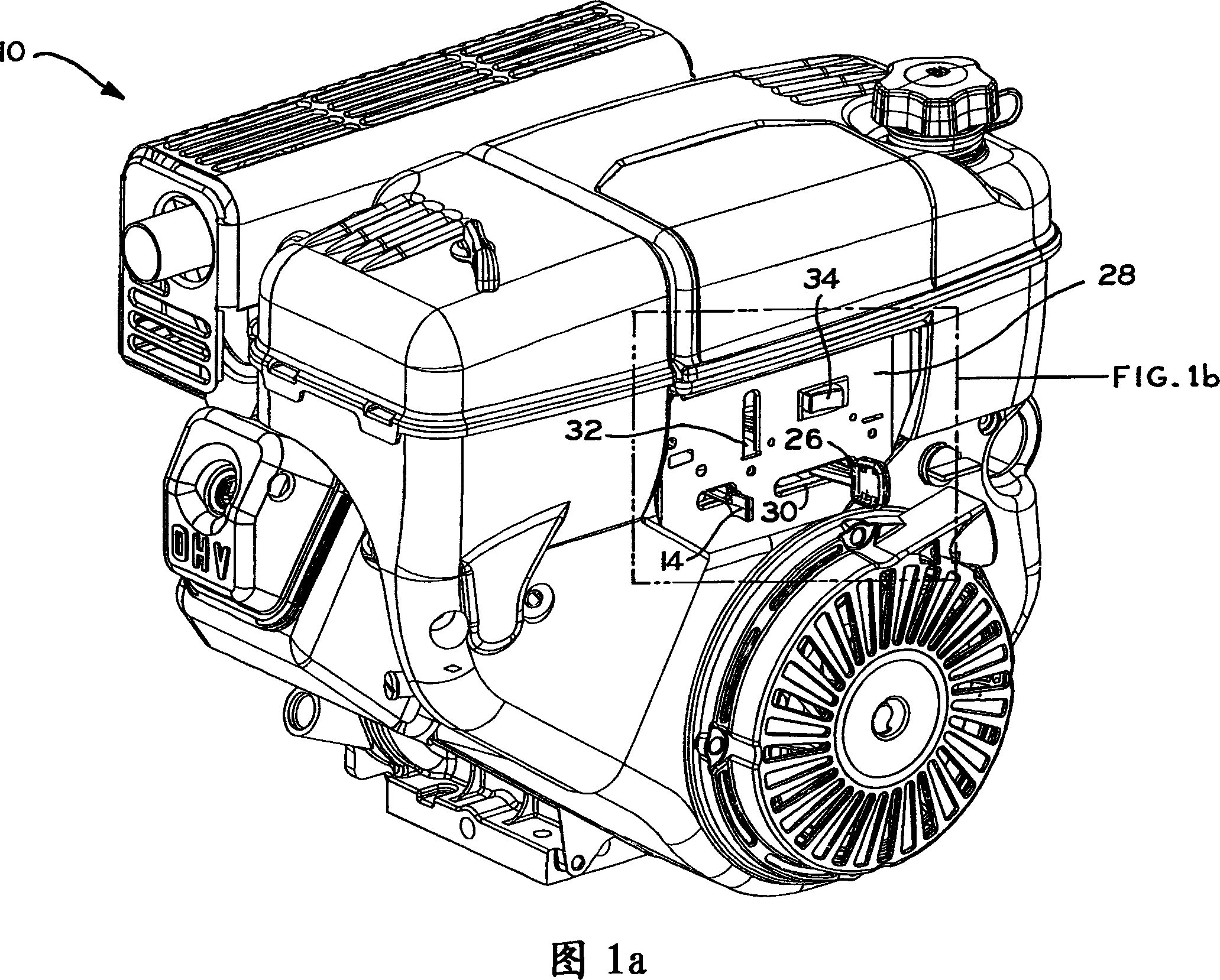

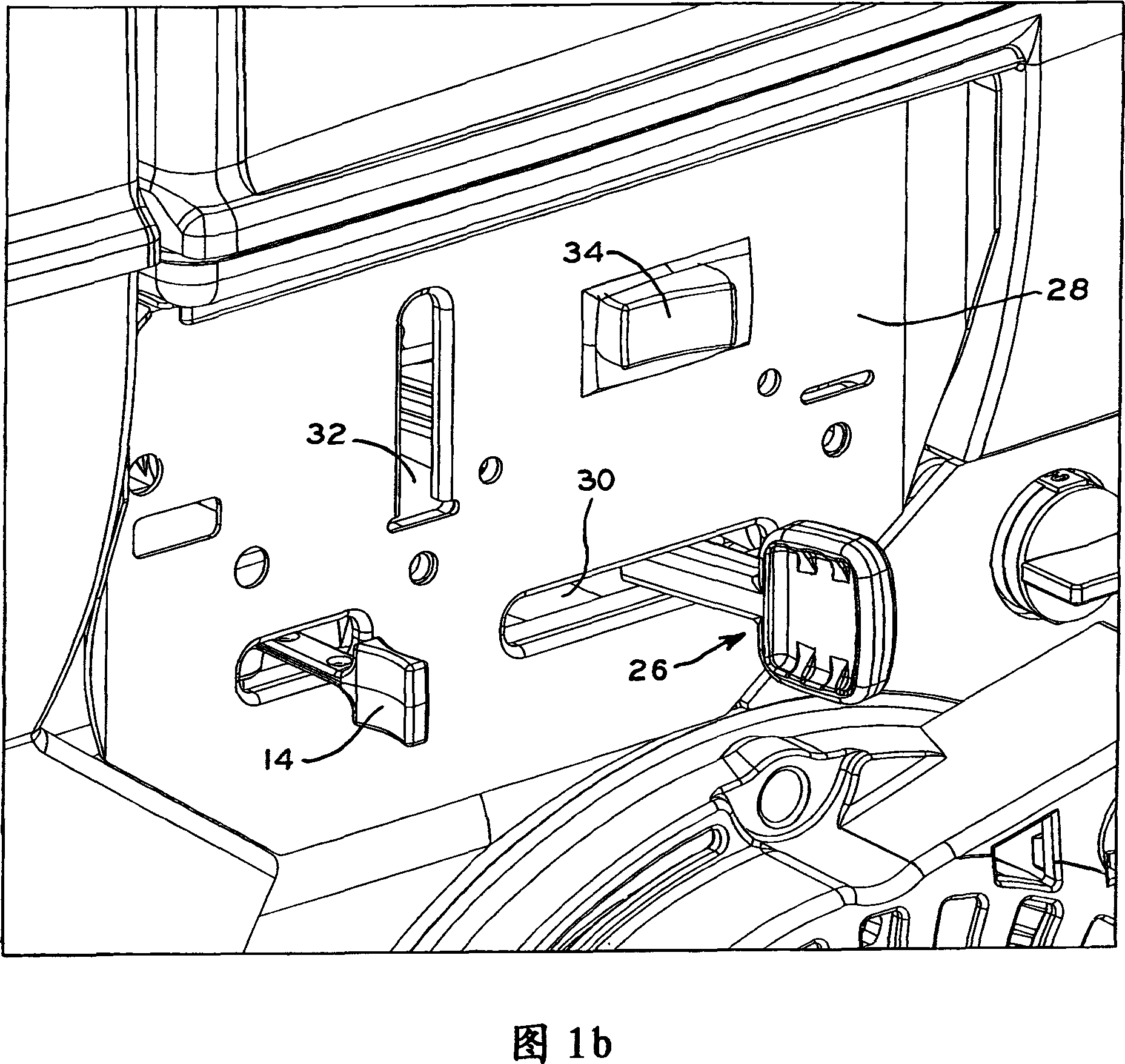

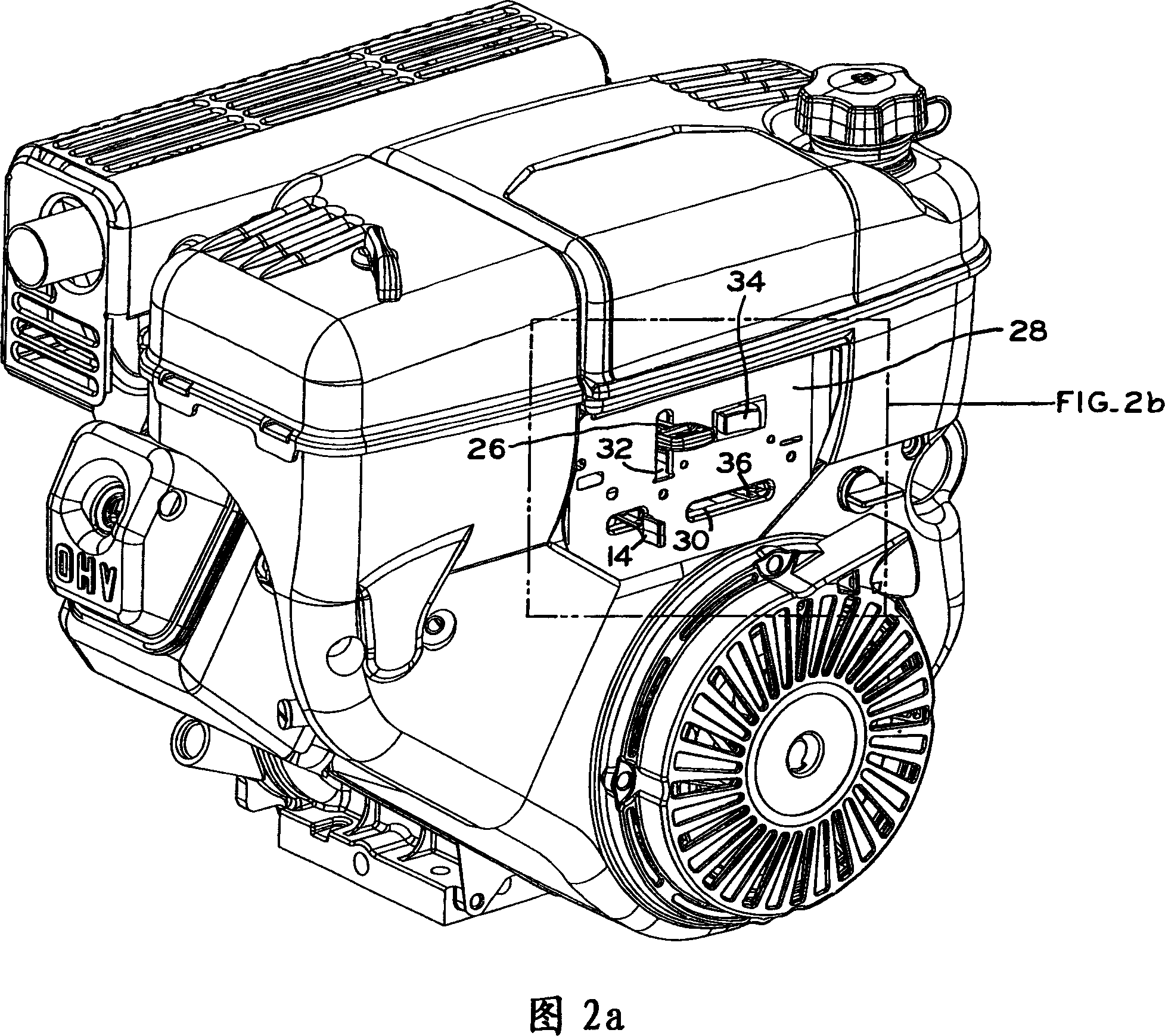

[0027] Referring to Figures 1a-2b, there is shown a small internal combustion engine 10 which includes a speed control mechanism according to the present invention.

[0028] Engine 10 may be a small internal combustion engine of the type produced by Tecumseh Power Company of Grafton, Wisconsin, and includes known components not visible in the drawings, including the crankcase and connection to the crankshaft A cylinder block on the case that includes one or more bores for receiving pistons. Each piston is connected with a crankshaft of engine 10 via a connecting rod. The engine 10 shown here is a horizontal crankshaft engine; however, the invention is equally applicable to vertical crankshaft engines. Some typical motors that may be used with the speed control mechanism of the present invention as will be described below are disclosed in U.S. Patent No. 6,295,959, No. 6,612,275 and No. 6,941,914, each of which is assigned to the assignee of the present invention , the conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com