Vencore flowmeter

A flowmeter and cone-shaped technology, which is applied in the field of flowmeters with high measurement accuracy, can solve the problems of unstable outflow coefficient, low repeatability, and small range, and achieve small permanent pressure loss, high measurement accuracy, and flow measurement wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

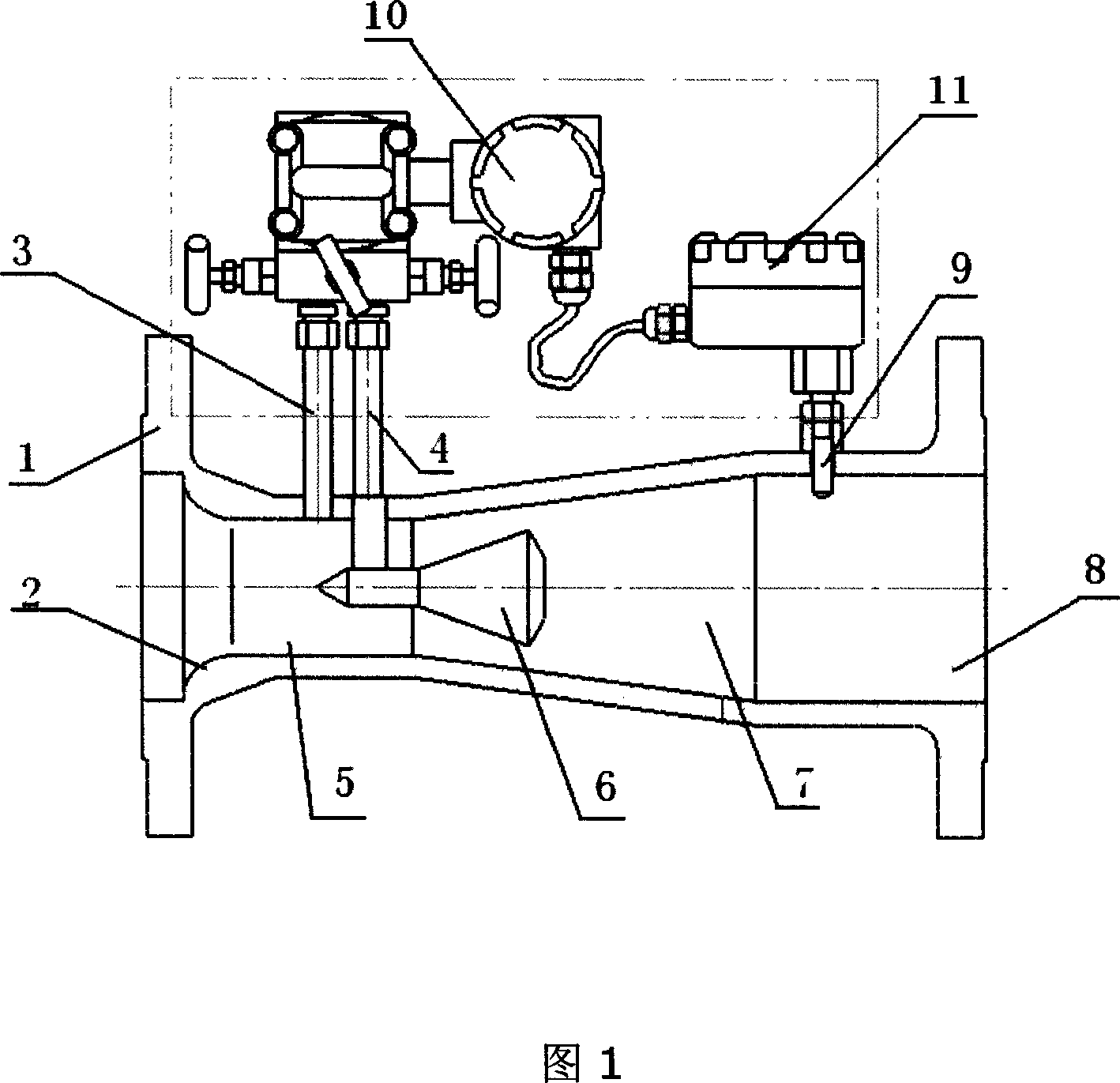

[0016] Below in conjunction with accompanying drawing 1, the specific embodiment of the present invention will be further described. This embodiment is a Venké cone flowmeter that can simultaneously detect the pressure and temperature of a fluid medium. The inlet and outlet ends of the Venturi tube are provided with flanges (1) connecting the pipeline. The inlet of the Venturi tube is a Venturi nozzle (2), followed by a straight throat section (5), followed by a 15-degree Taper-shaped diffuser pipe section (7), two holes are opened on the throat pipe section of the Venturi tube, which are respectively sealed and connected with the high-pressure pressure pipe (3) and the low-pressure pressure pipe (4) of the flow parameter conversion device, wherein , the low-pressure pressure-taking pipe extends into the diversion cone (6), the diversion cone is fixedly connected to the low-pressure pressure-taking pipe, and the position of the diversion cone is placed between the throat strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com