High frequency heating device

A high-frequency heating device and high-frequency technology are applied in the direction of induction heating to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. It should be pointed out that this embodiment does not limit the scope of the present invention.

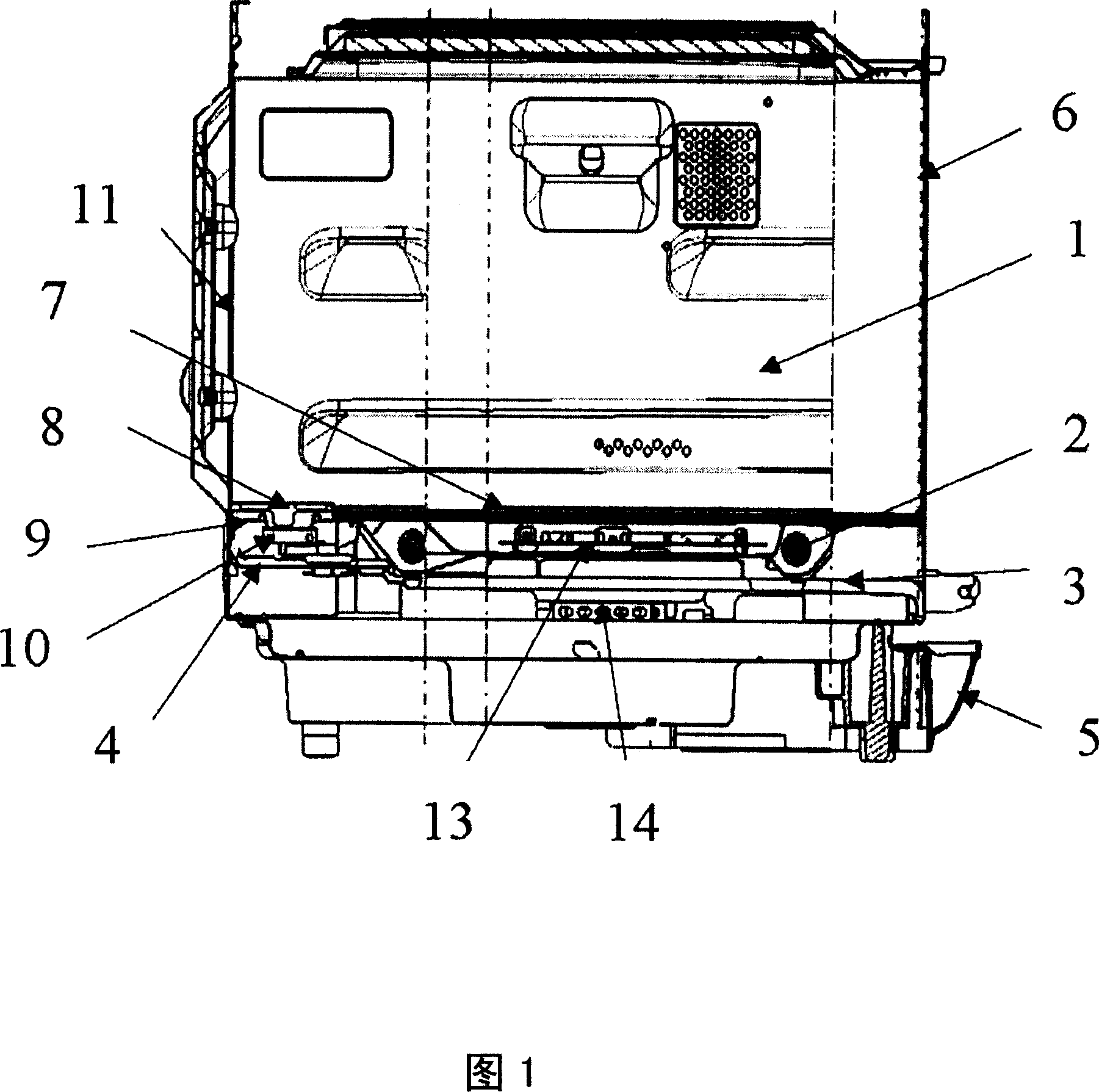

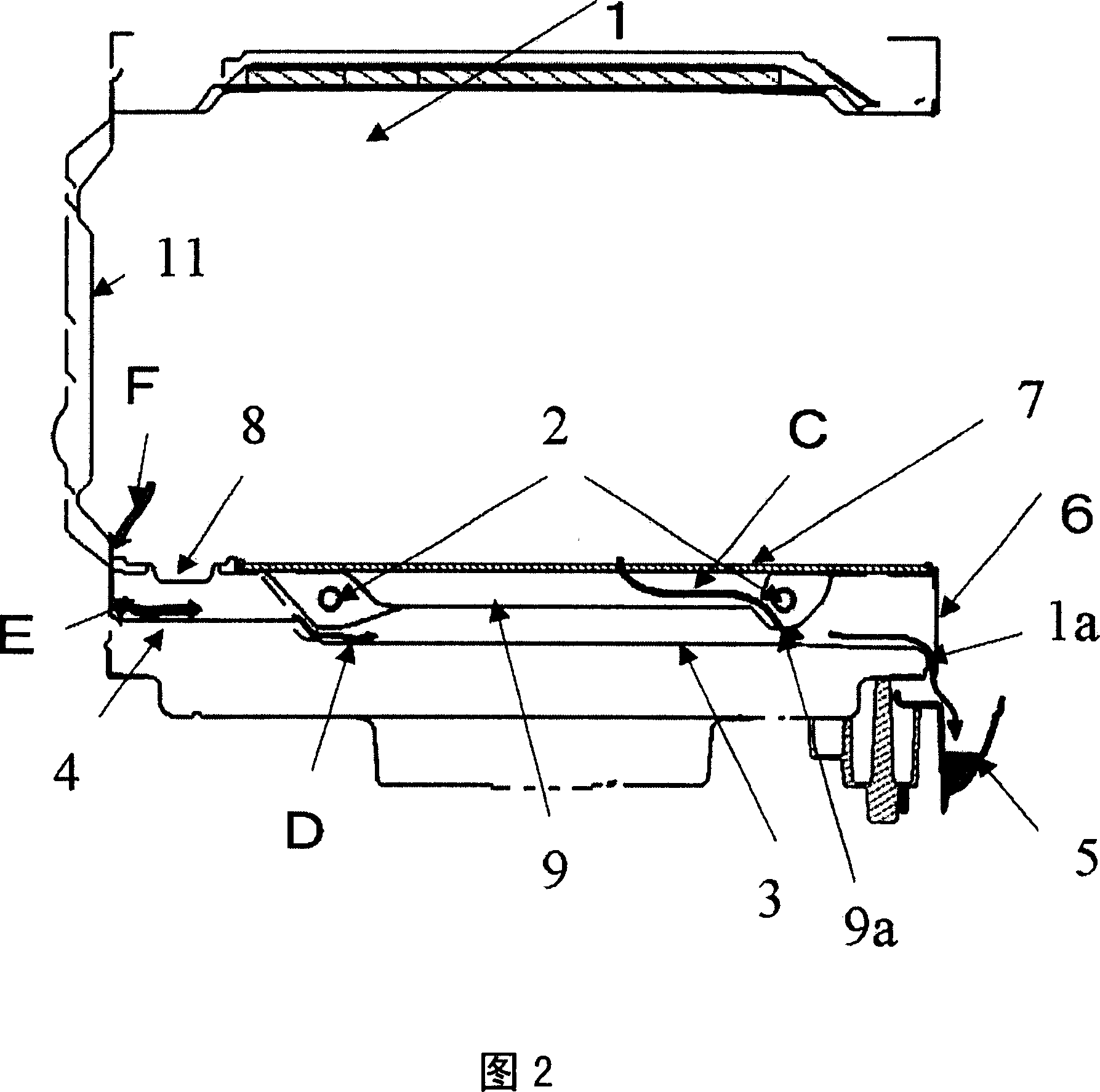

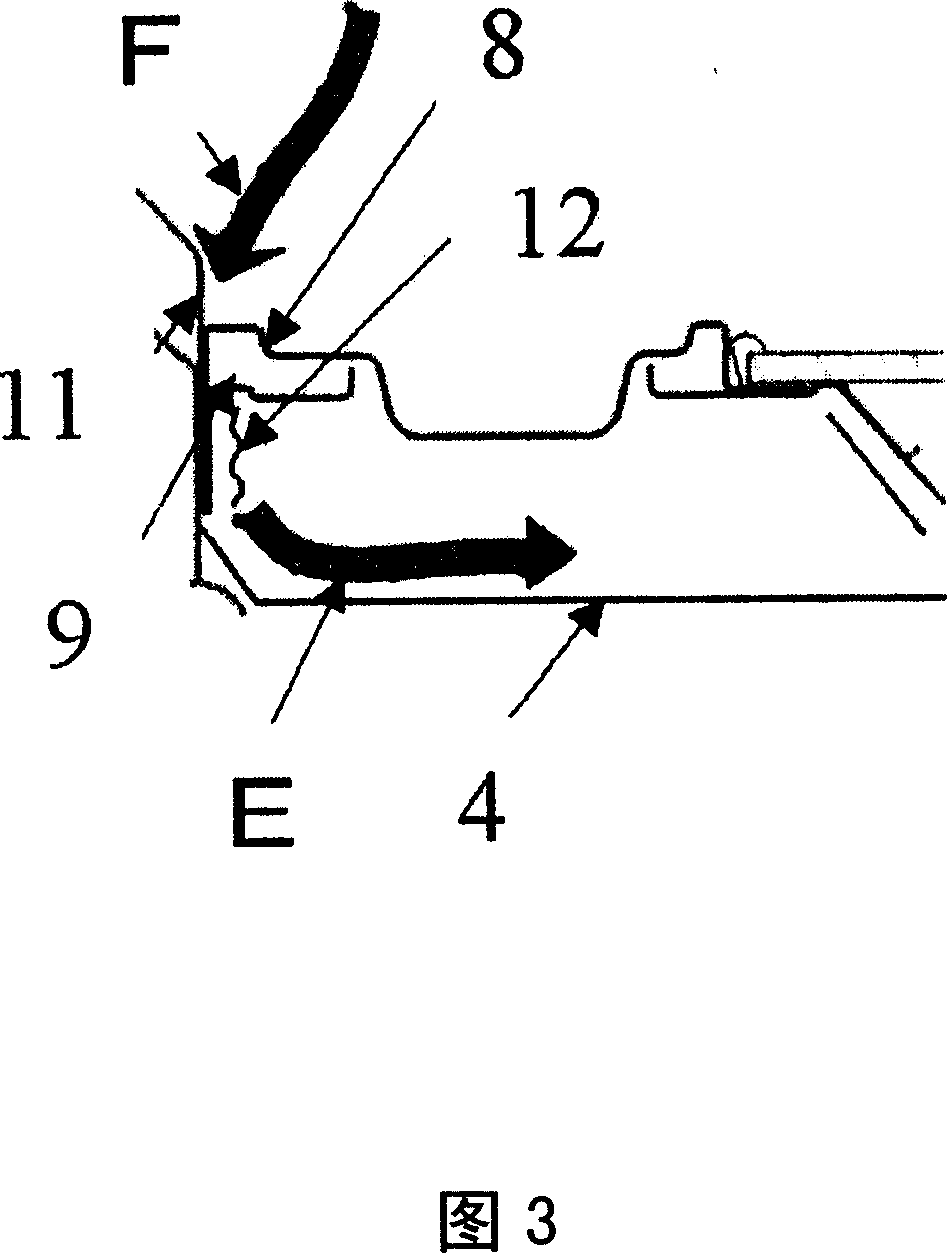

[0022] Fig. 1 is a side sectional view of the high-frequency heating device in Embodiment 1 of the present invention, Fig. 2 is a side sectional view for expressing the drainage water flow therein, Fig. 3 is a partial enlarged sectional view of Fig. 2, Fig. 4 And Fig. 5 is a perspective view for showing the drainage water flow.

[0023] As shown in Fig. 1, be provided with in the heating chamber 1: be used to place the ceramic stage 7 of object to be heated; Constitute the heater 2 of the electrothermal device that is heated to object to be heated; The rotating waveguide 13 of the high frequency generating device. In addition, the above-mentioned heating chamber 1 is combined by riveting the evaporating dish 8, the rear wall 11 of the heating chamber and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com