Mechanism for filling combined paper cylinder fireworks with round paper scraps

A technology of combining fireworks and circular paper, which is applied to fireworks, offensive equipment, weapon types, etc., can solve problems such as many problems and failures, difficult to unify the specifications of paper tubes, and the machine cannot successfully complete the plugging of circular paper, so as to improve production. Efficiency, the effect of preventing product quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

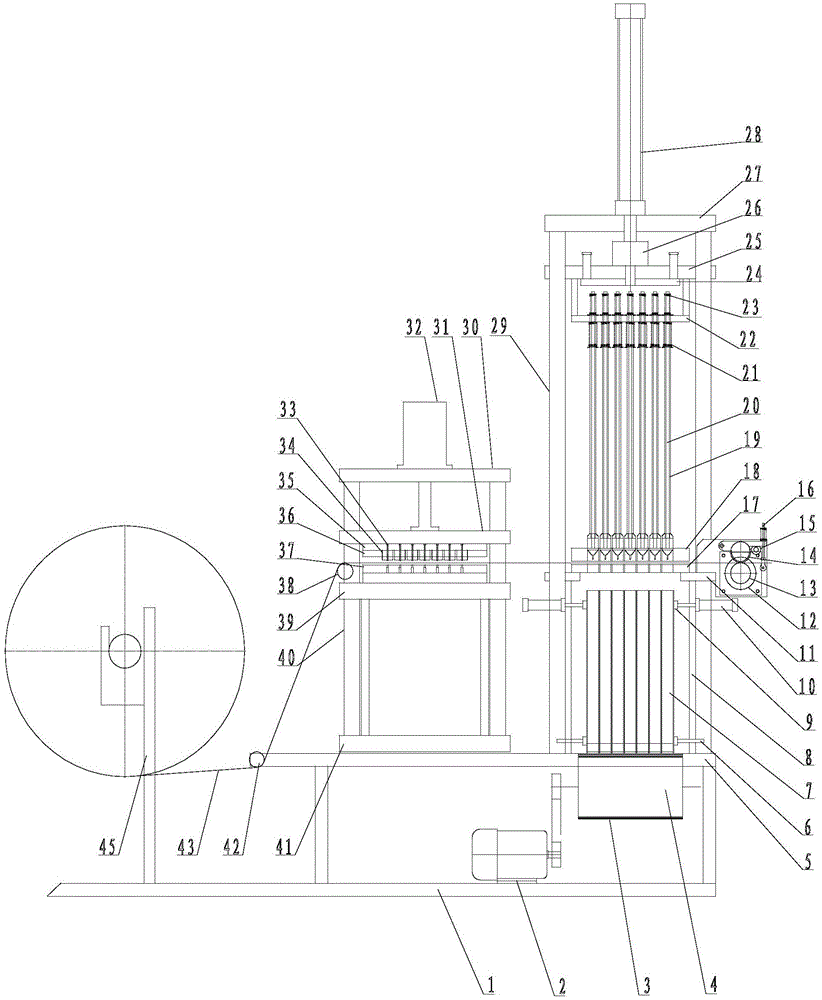

[0037] Embodiment 1: see attached Figure 1-10 , reflecting a specific preferred structure of the present invention, the paper tube combined firework disc stamping and plugging equipment includes a paper feeding mechanism installed on the frame 1, a disc stamping mechanism, a disc plugging mechanism, a firework Conveyor:

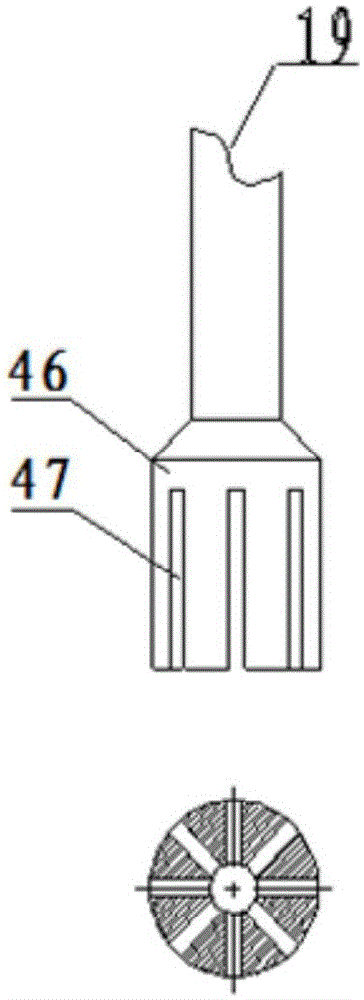

[0038] Paper feeding mechanism: welded to the upper paper frame 45 of the frame 1, the upper paper frame 45 is equipped with a roll-shaped paper 43 to be processed, the paper passes through the frame passing paper shaft 42 and the punching machine passing paper shaft 38, and passes through the punching machine. The front paper gap between the pin anvil 37 and the punching needle 33 passes through the paper gap between the separation template 17 and the positioning template 18, and the waste paper after stamping and plugging is sent by the feeder installed on the module fixing plate 11. The paper shaft 13 and the paper feeding platen shaft 14 are clamped and...

Embodiment 2

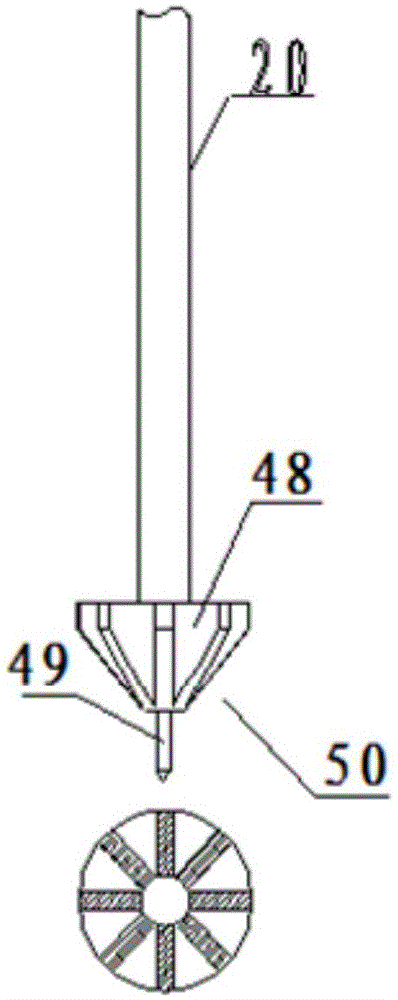

[0049] Example 2: The difference from Example 1 is that see Figure 11-14The lower end of the paper pressing rod 101 is fixedly connected to the cylindrical paper pressing head 102, and the side of the cylinder has no axial groove. The lower end of the telescoping pick-up rod 103 is fixedly connected with the conical guiding working head 104 , and the conical top position of the conical guiding working head 104 is provided with a paper pick-up needle 105 . The conical guiding working head 104 is a cone made of a solid body, not a prism. The cone bottom of the cone is smaller than the size of the bottom surface of the cylinder body of the paper pressing head 102, so that the cone can expand and contract in the inner cavity of the cylinder, so that the conical guide working head 104 and the paper pick-up needle 105 are connected with the paper pressing head 102. The positional relationship switches between the A state and the B state. The disadvantage is that the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com