Ceramic substrate

A ceramic substrate, ceramic thin plate technology, applied in printed circuit components, electrical components, printed circuits, etc., can solve the problem of large-scale ceramic substrates, and achieve the effect of reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

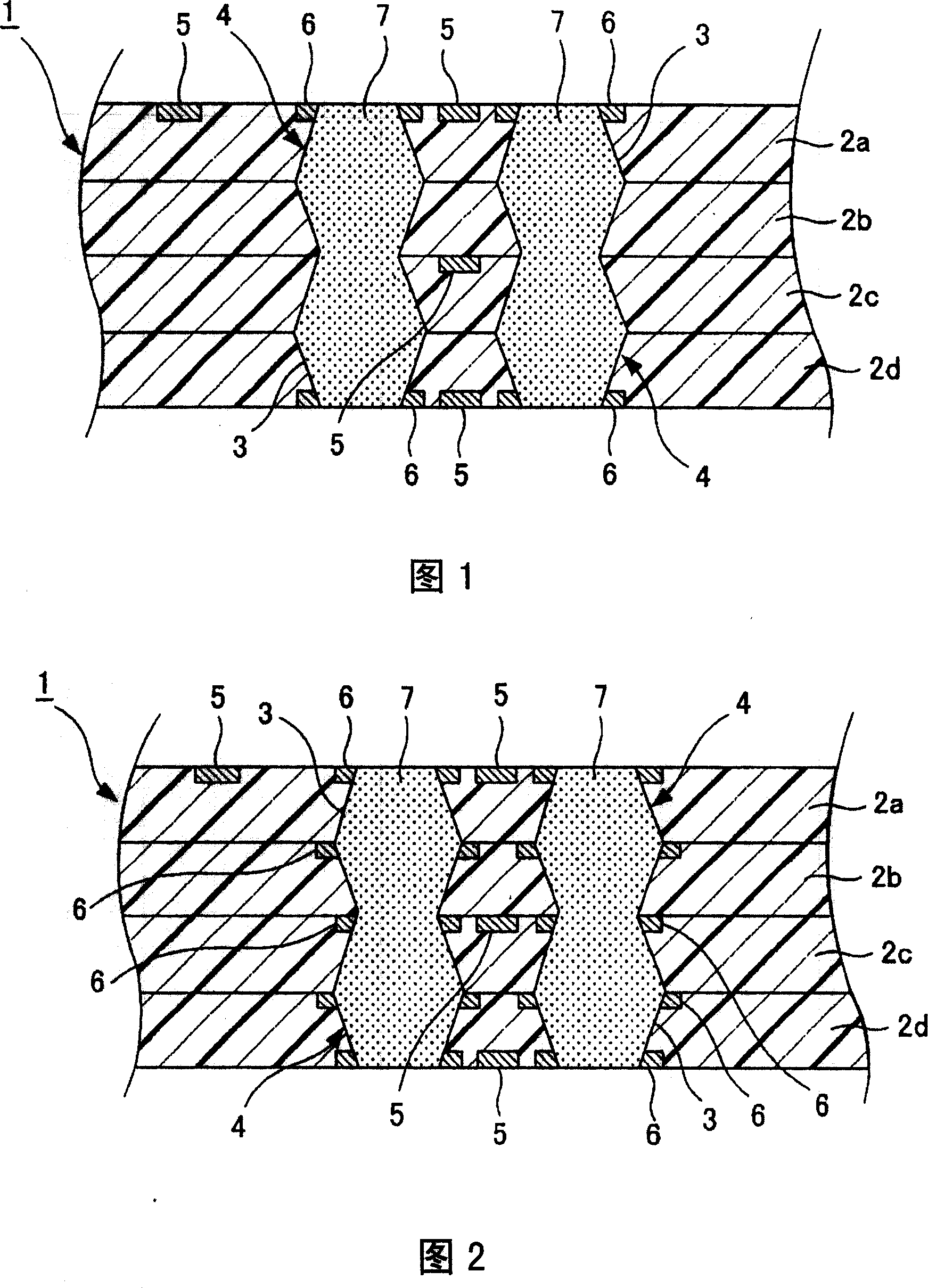

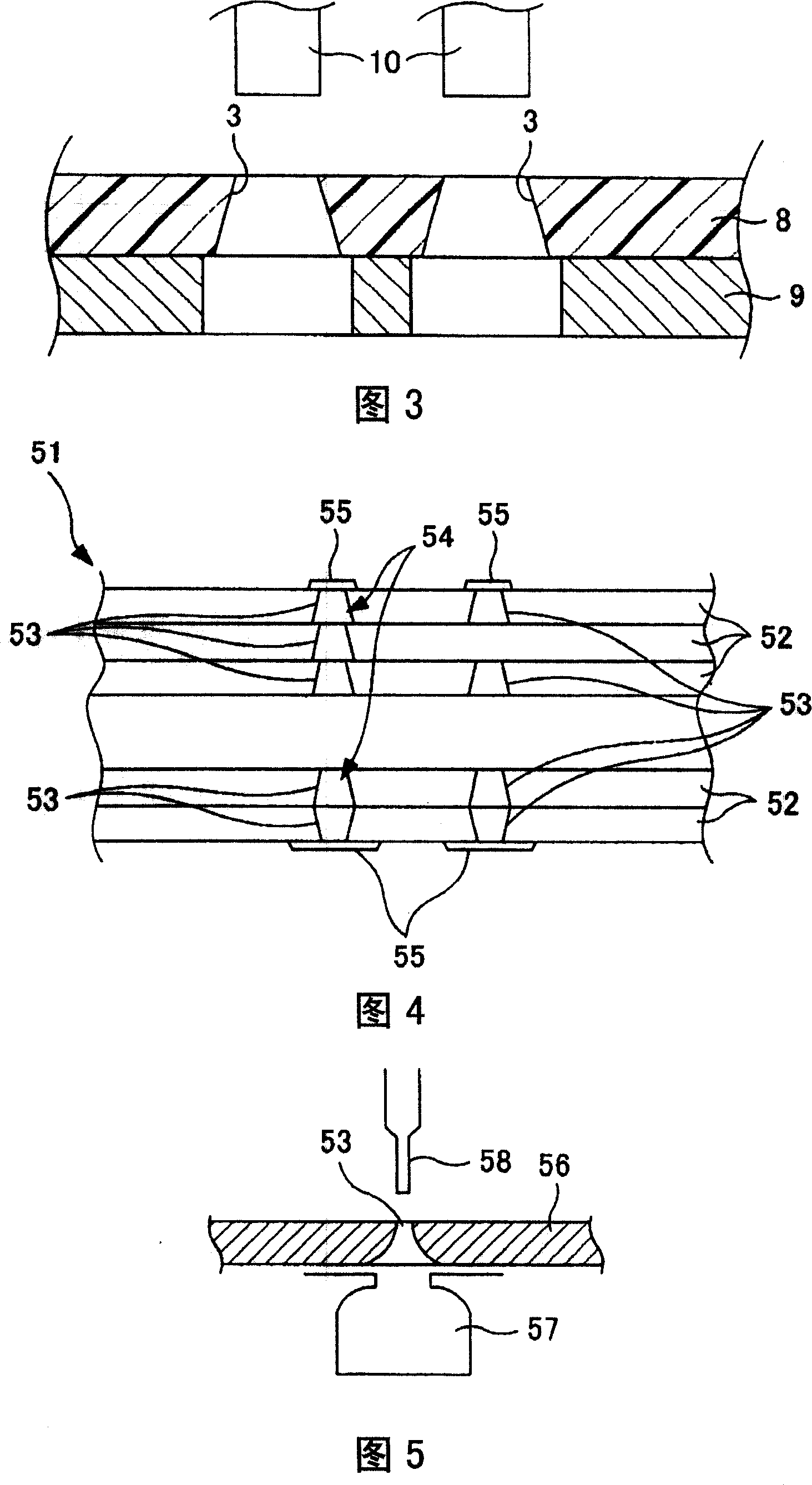

[0030] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 is a sectional view of main parts of a first embodiment of a ceramic substrate of the present invention, and FIG. 2 is a sectional view of main parts of a second embodiment of a ceramic substrate of the present invention. , FIG. 3 is an explanatory view showing a method of manufacturing a ceramic substrate of the present invention.

[0031] Next, the structure of the first embodiment of the ceramic substrate of the present invention will be described with reference to FIG. 1. The ceramic substrate 1 is made of low-temperature co-fired ceramics (LTCC) or the like, for example, by laminating a plurality of (four) ceramic thin plates 2a to 2d. And formed.

[0032] The ceramic thin plates 2a-2d are provided with holes 3 formed in the shape of a cone, and the holes 3 are connected to each other in the vertical direction to form a through hole (a state in wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap