Power coupler for mixed power automobile

A hybrid vehicle and power coupling technology, which is applied to hybrid vehicles, power plants, pneumatic power plants, etc., can solve the problems of complex control of planetary gear mechanisms, uncompact drive train structure, and high requirements for manufacturability, and achieve simplification. New design and trial production, eliminating the effect of simplifying the transmission and other mechanisms and systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

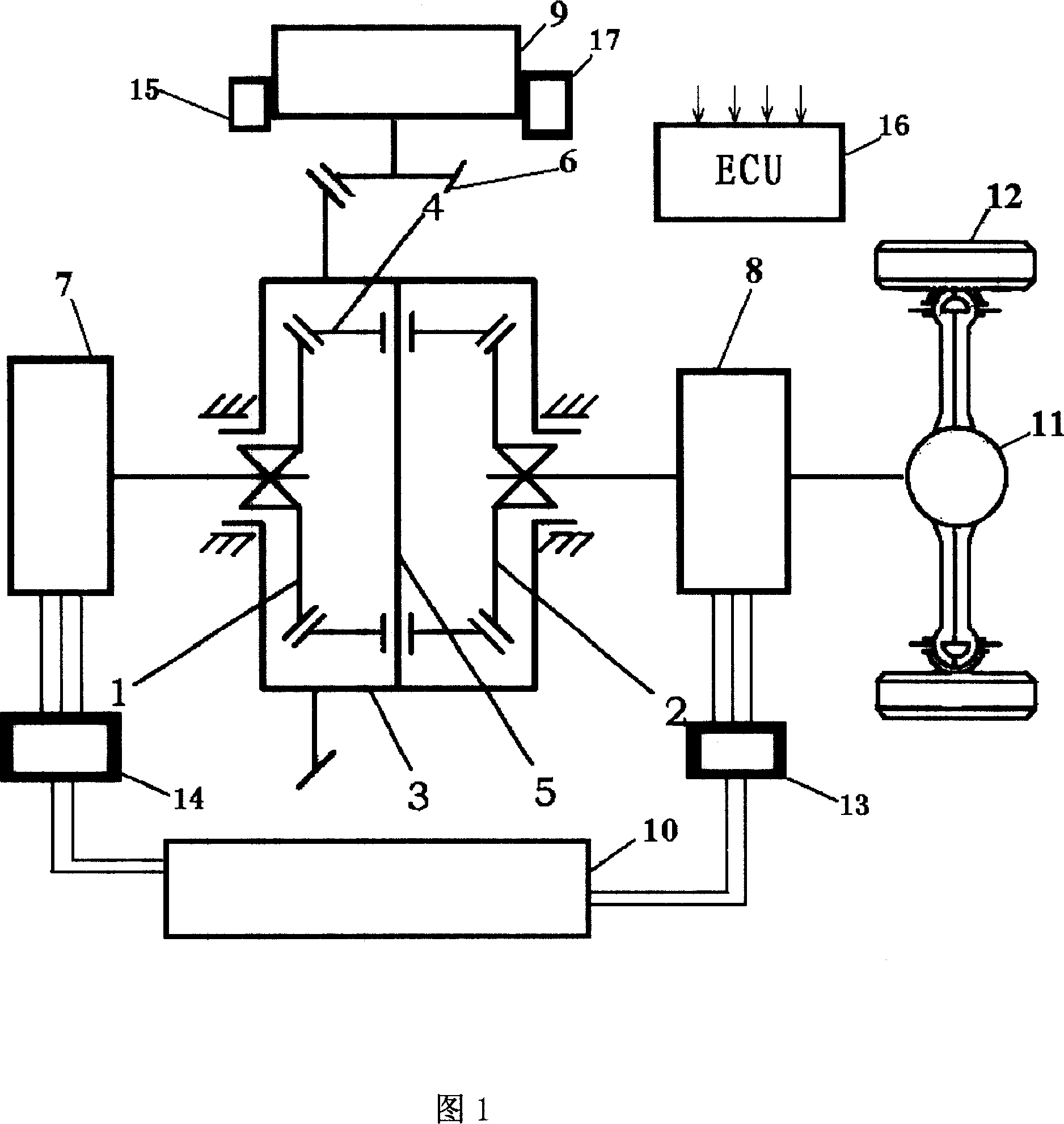

[0041] Referring to Fig. 1, the described power coupling device of hybrid electric vehicle is to adopt traditional differential gear, realizes the power distribution between power sources (generator 7, electric motor 8, engine 9) in hybrid electric vehicle driving system with work. The left side gear 1 and the right side gear 2 of the differential are respectively connected to the generator 7 and the motor 8 through the left and right side shafts, the driving gear 6 of the final drive is fixedly connected to the output shaft of the engine 9, and the final drive The driving gear 6 of the main reducer and the driven gear 3 of the main reducer are meshed in the state that the two rotation axes are coplanar and perpendicular to each other. The driven gear 3 of the final reducer and the left side shaft gear 1 are on the same rotation axis, The rotation axis of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com