High pressure method for producing pure melamine in a vertical synthesis reactor

A technology for synthesizing reactor and pure melamine, which is used in the reaction of liquid and gas at high temperature, chemical instruments and methods, and methods of chemically changing substances by using atmospheric pressure to achieve uniform urea conversion and reduce corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

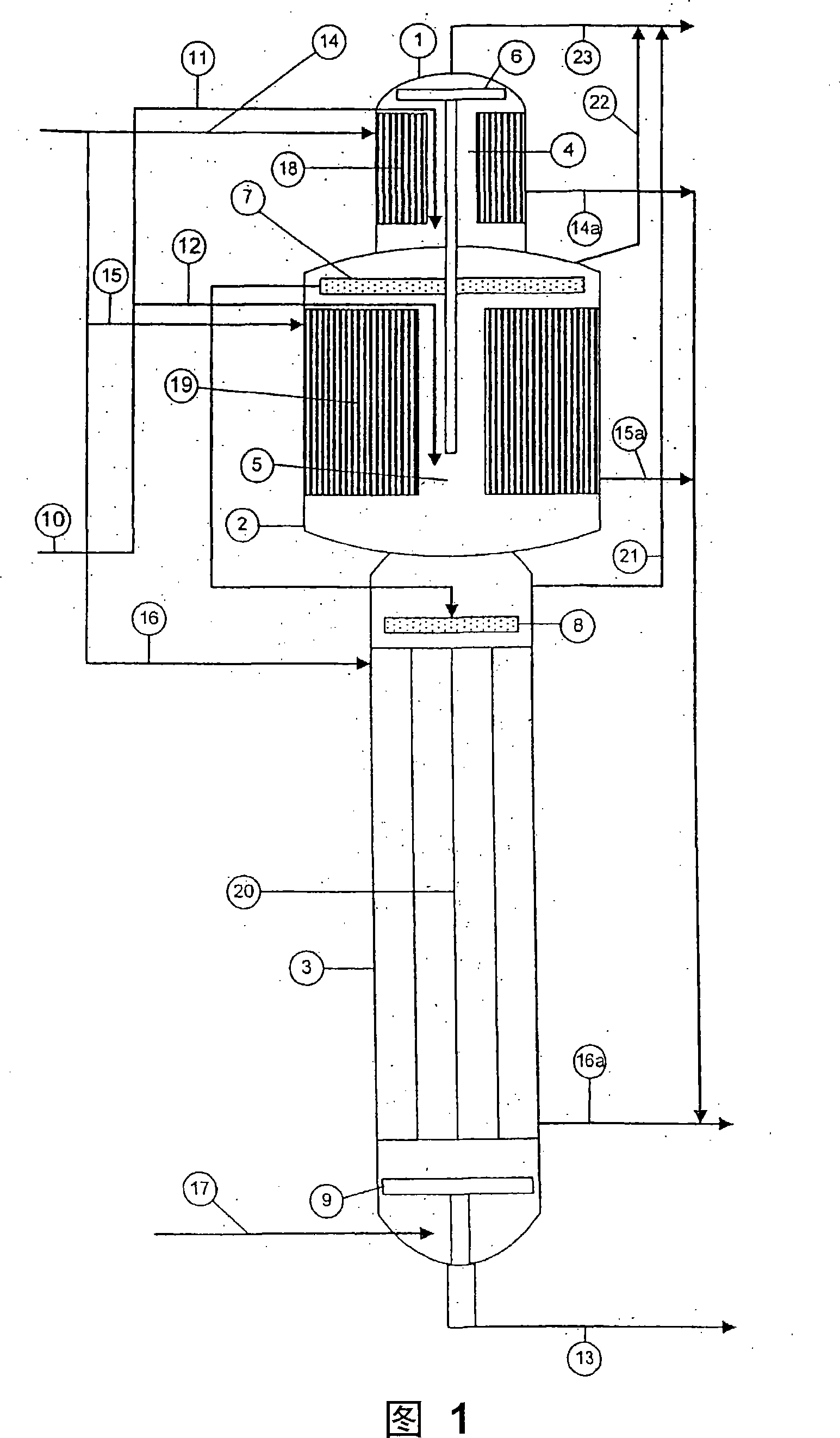

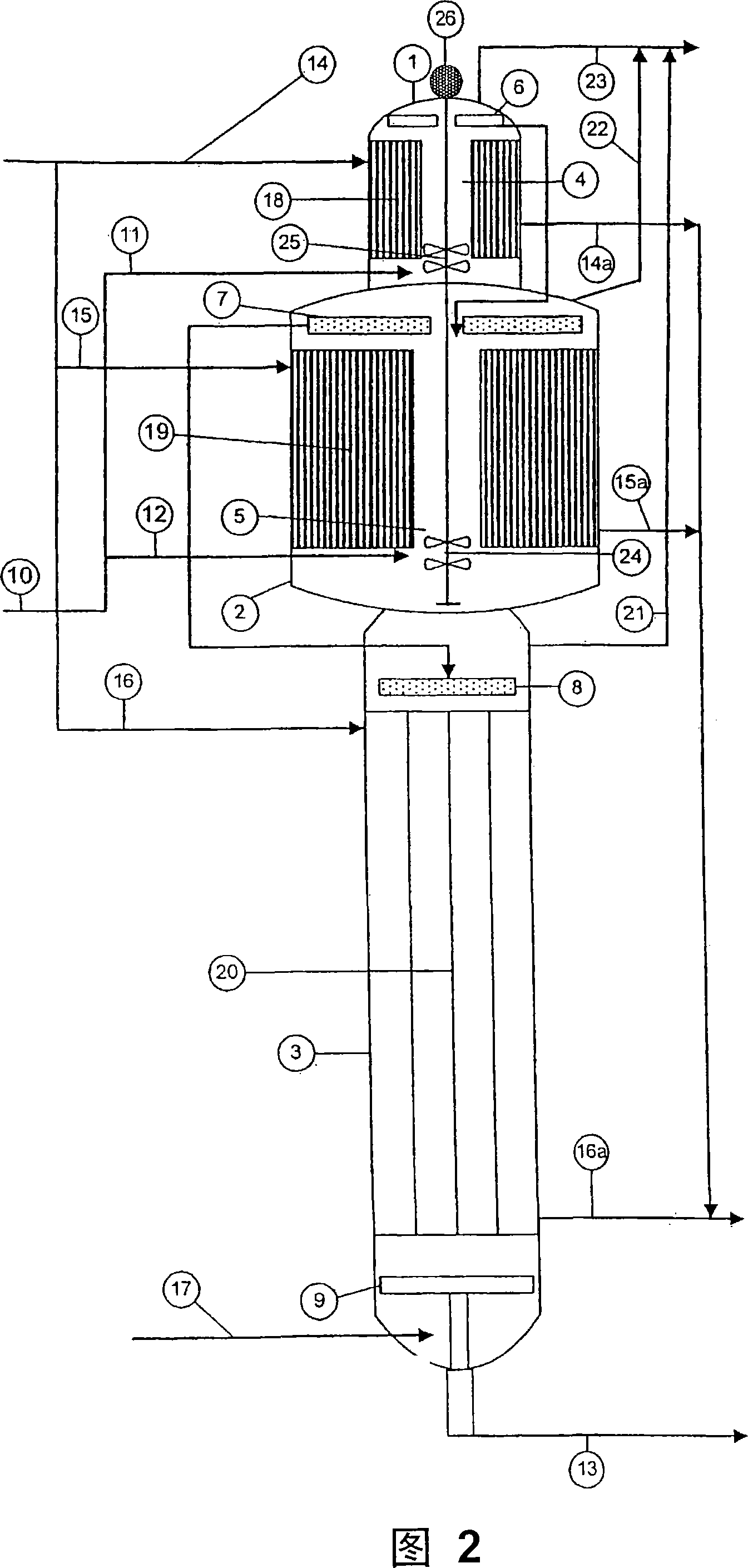

[0042] Fig. 1 and Fig. 2 show: the first and the second circulating reactor (1) and (2), falling film reactor (3), the central pipe of the first and the second circulating reactor ( 4) and (5), enter the storage tank and overflow pipe (6) in the second circulating reactor from the first circulation reactor, enter the storage tank in the falling film reactor from the second circulation reactor And overflow pipe (7), distributor (8), ammonia distributor (9), the introduction pipe (10) of all urea, the introduction pipe (11) of the urea flow in the first and second circulating reactor And (12), be used for the outlet pipe (13) of further processing melamine melt, the import pipe (14), (15) and (16) of salt melt, the outlet pipe (14a), (15a) of salt melt , (16a), NH 3 Gas inlet pipes (17), tube bundles (18), (19), (20) through which the salt melt flows as heat exchangers, waste gas pipes (21) from the falling film reactor, intermediate reaction The exhaust gas line (22) of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com