Paste coating apparatus

A gluing machine and coating technology, applied in spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve problems such as inappropriateness, achieve weight reduction, less cable wear, and reduce signal errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

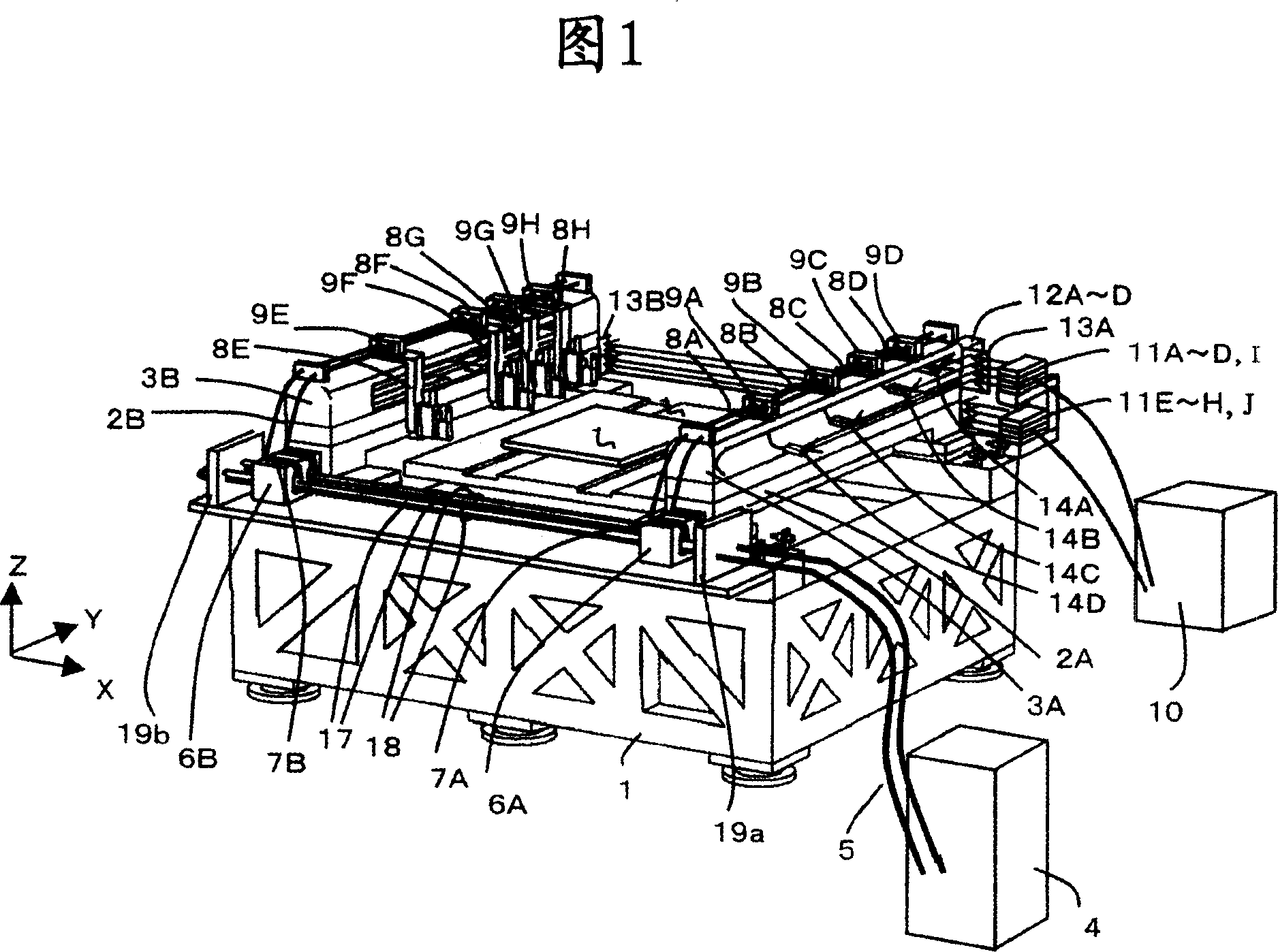

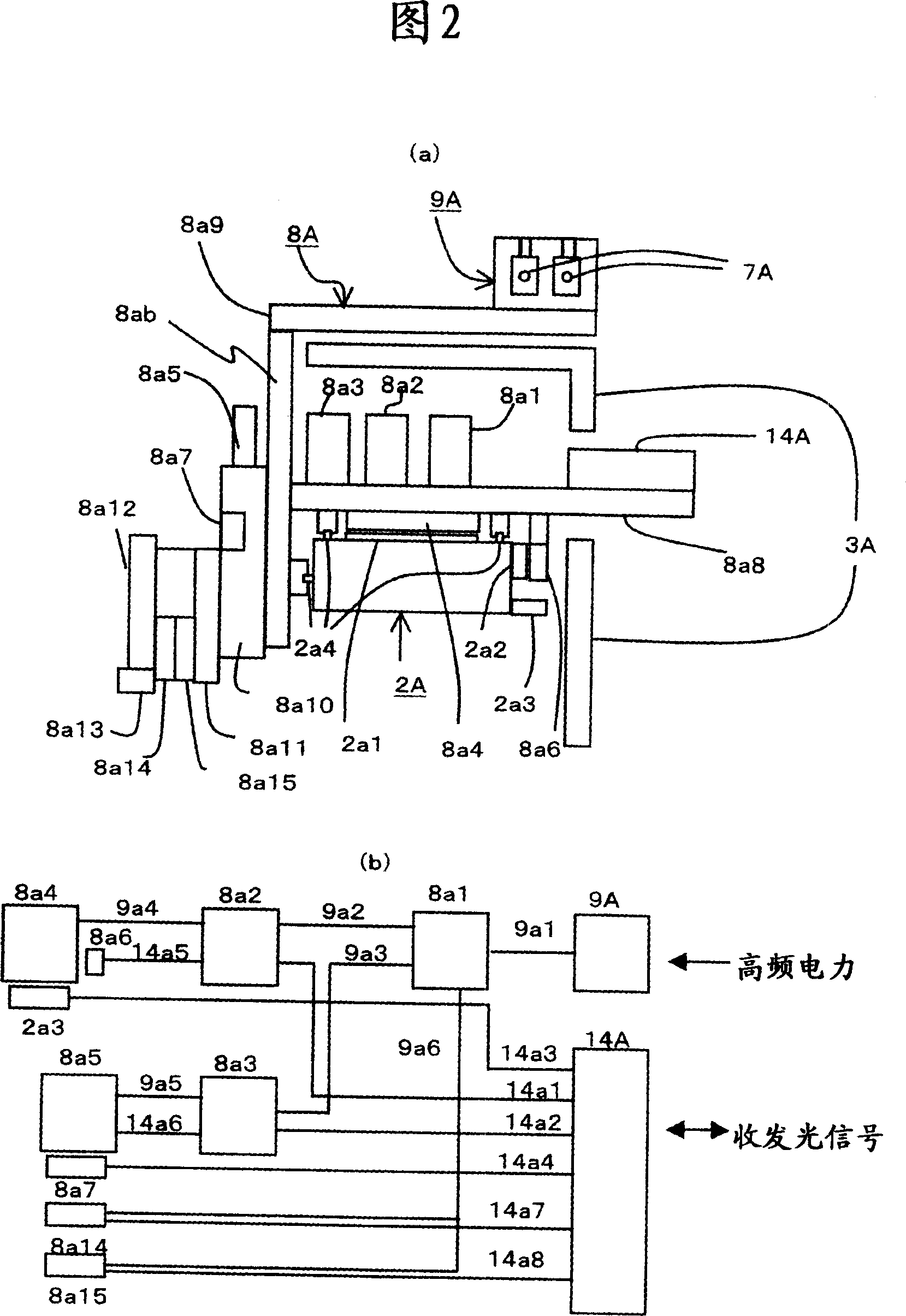

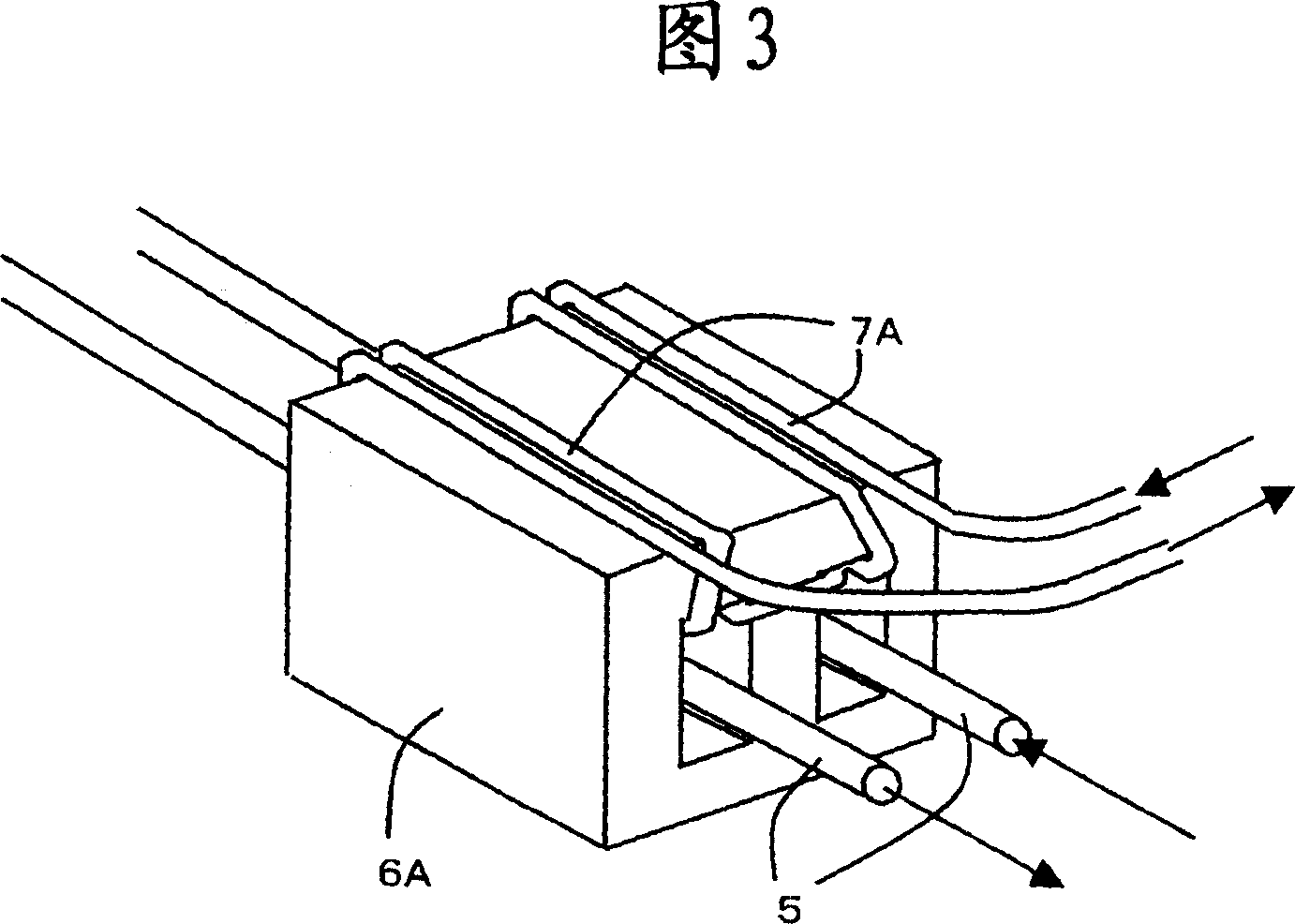

[0015] The present invention is a technology for saving power supply to a motor that drives an applicator head or power supply or signal wiring connected to a door frame for transmitting sensor signals. That is, the motor driver is set on the gantry (gantry), and the power feeding method to the driver is set as a feeder line laid in the door-type moving direction and a power-receiving pick-up (power-receiving core) installed on the door-shaped frame. In the non-contact power feeding method composed of sub), the feeding pick-up head is also set in each coating head, so that the power is received from the feeding wires wired on the door frame. Furthermore, the signal line from the main control unit to the driver is optical wireless communication. As a result, the number of movable cables following the door frame is reduced, thereby reducing dust and man-hours for wiring work. Hereinafter, its structure and operation will be described in detail using examples.

[0016] Hereinaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com