Paviny type jointable prefabricated road-face brick combined structure

A combined structure and pavement technology, applied in the field of building materials, can solve the problems of vertical embedding constraints, low horizontal tensile strength, increased road maintenance costs, lack of overall cooperative resistance of pavement bricks, etc., and achieve good anti-foreign object entry and exit effects , Maintain overall stability and avoid the effect of adjacent bricks being misplaced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

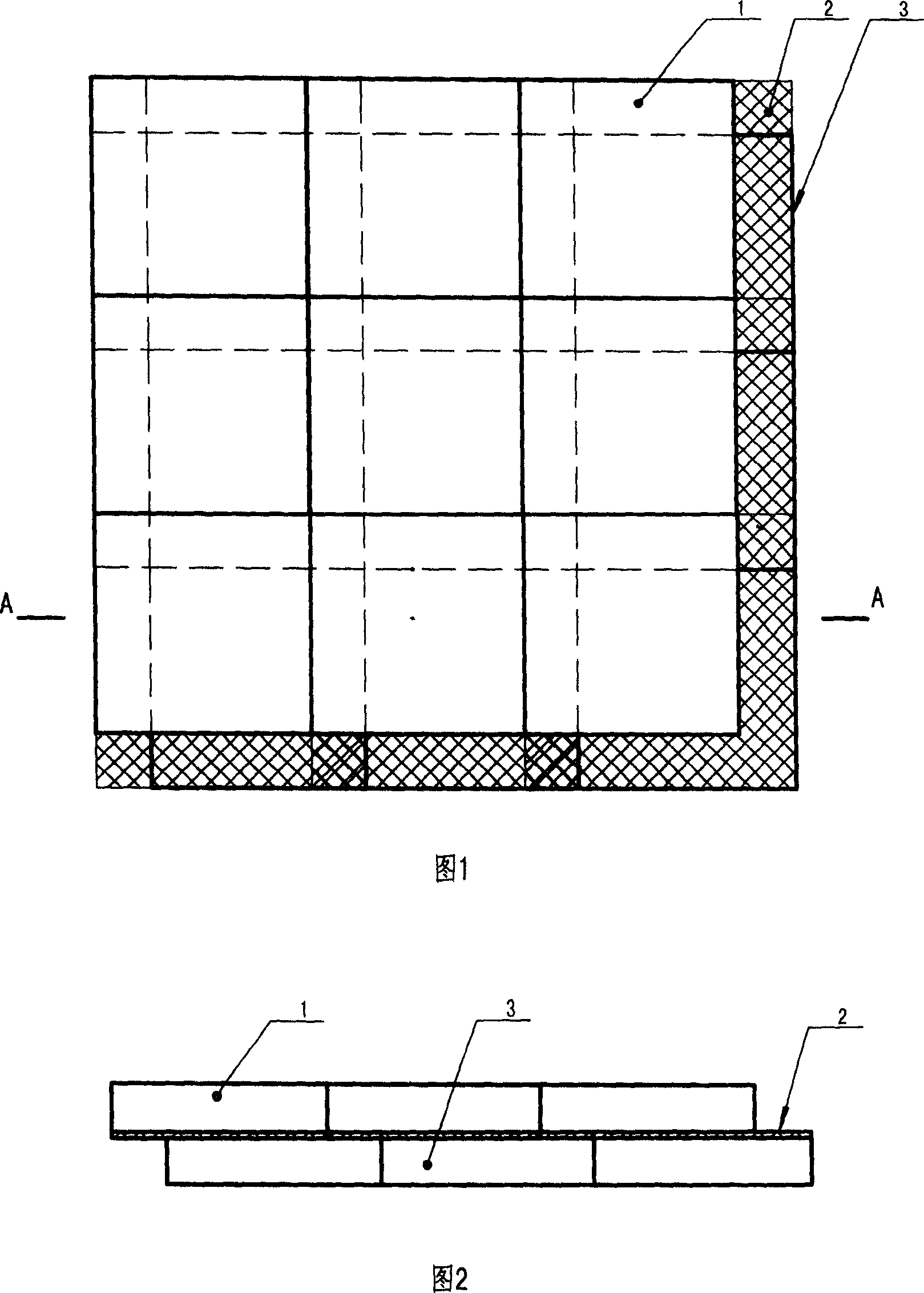

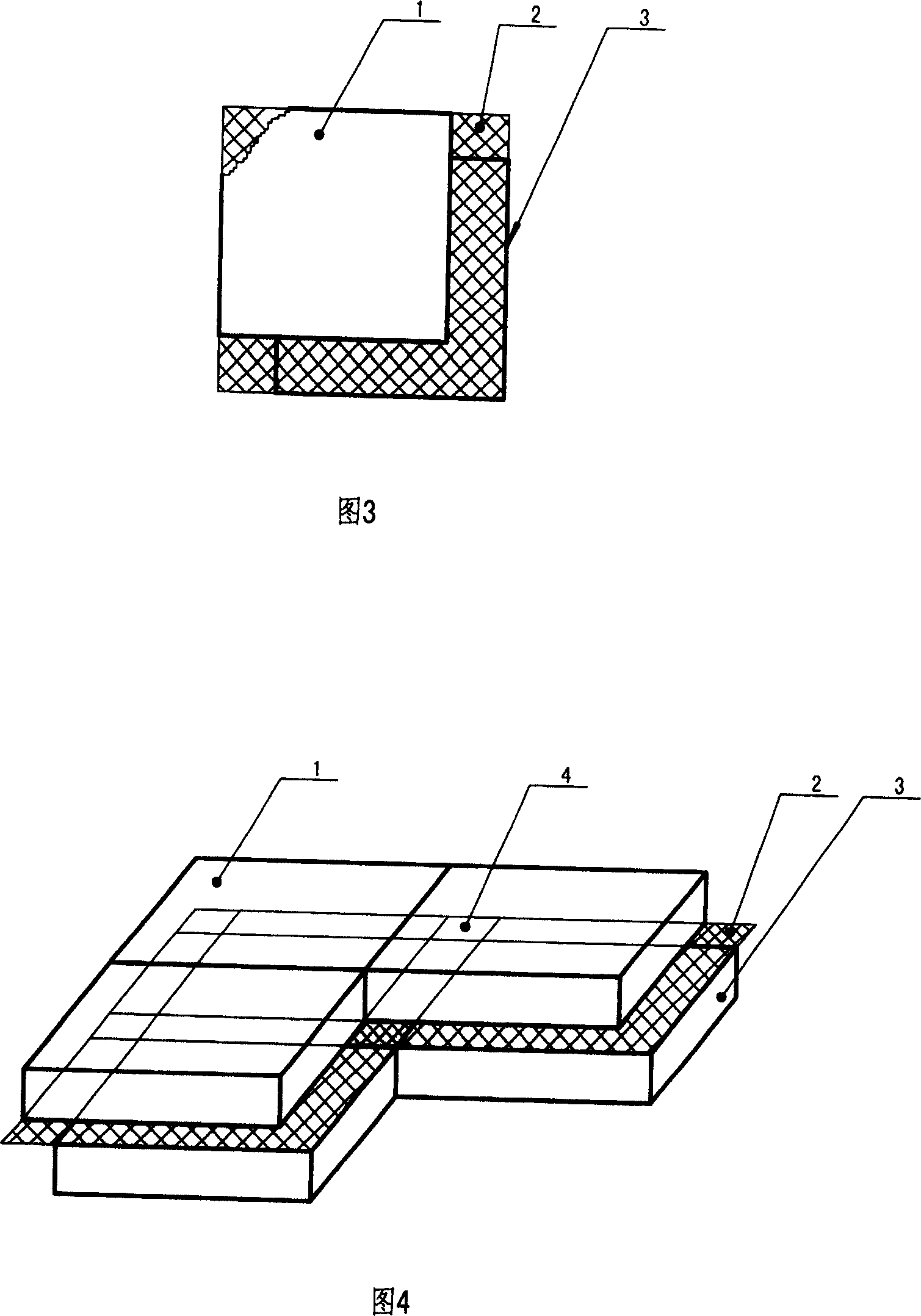

[0019] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0020] The pavement type connectable prefabricated pavement brick composite structure of the present invention is a product prefabricated in a factory by inorganic cementitious mixed materials such as concrete (including ordinary concrete, Portland concrete, porous concrete, industrial waste slag concrete, and stone chip concrete). Square pavement bricks are divided into upper pavement brick 1 and lower pavement brick 3. The upper and lower pavement bricks are of the same size and arranged along the diagonal of the upper plane of the square pavement brick. The side length of the upper pavement brick and the lower pavement brick The ratios are: thickness=10:1-4, preferably 10:2. The dislocation distance between the pavement bricks of the upper layer and the pavement bricks of the lower layer along the diagonal direction is 1-10 cm, preferably 3 cm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length size | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com