Methods of generating exergy

A technology of effective energy and thermal energy, applied in the direction of steam engine device, steam recovery, machine/engine, etc., can solve the problems of low thermodynamic efficiency, preventing conversion efficiency, limited technical potential, etc., and achieve the effect of improving thermodynamic efficiency and conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

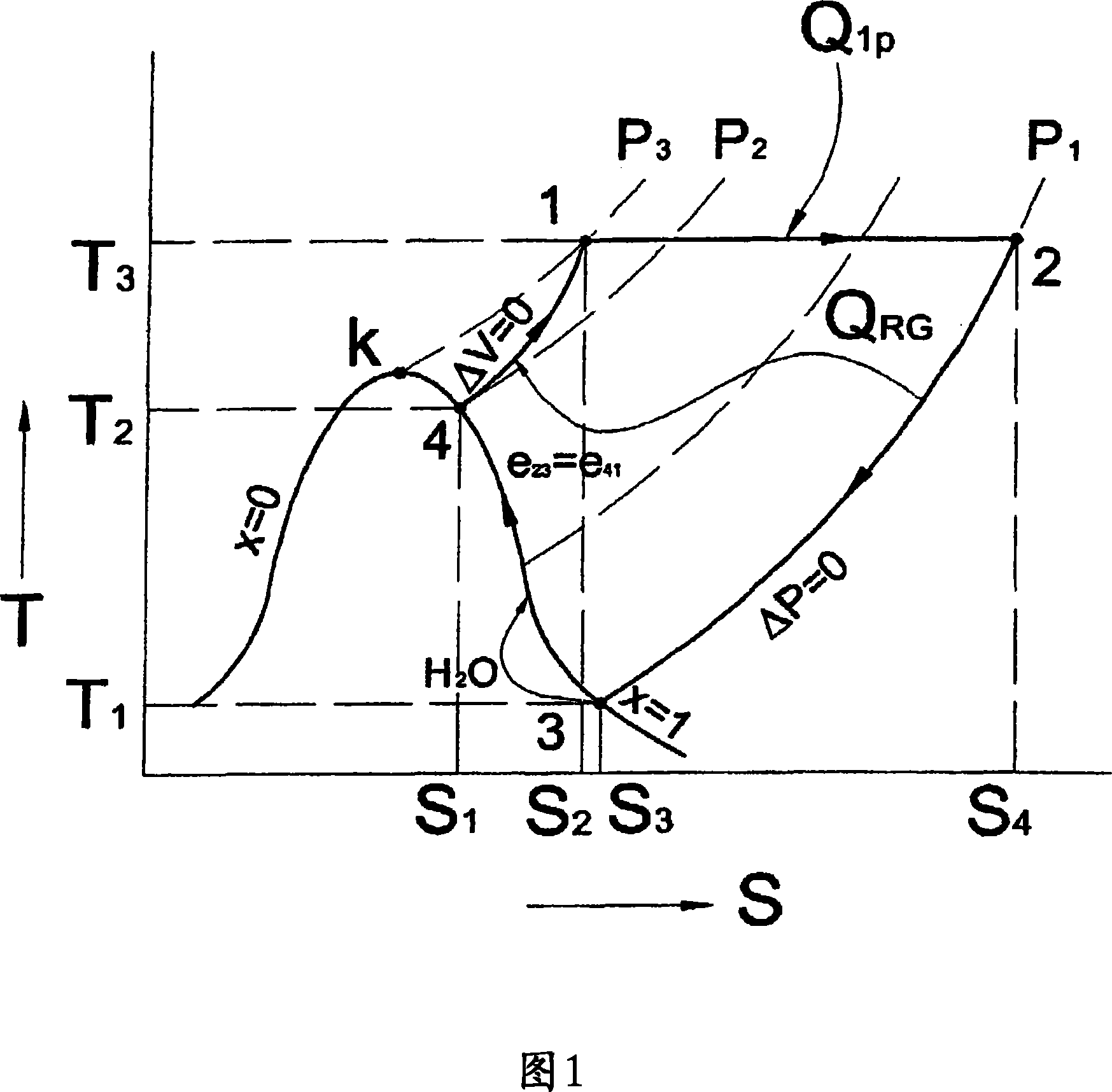

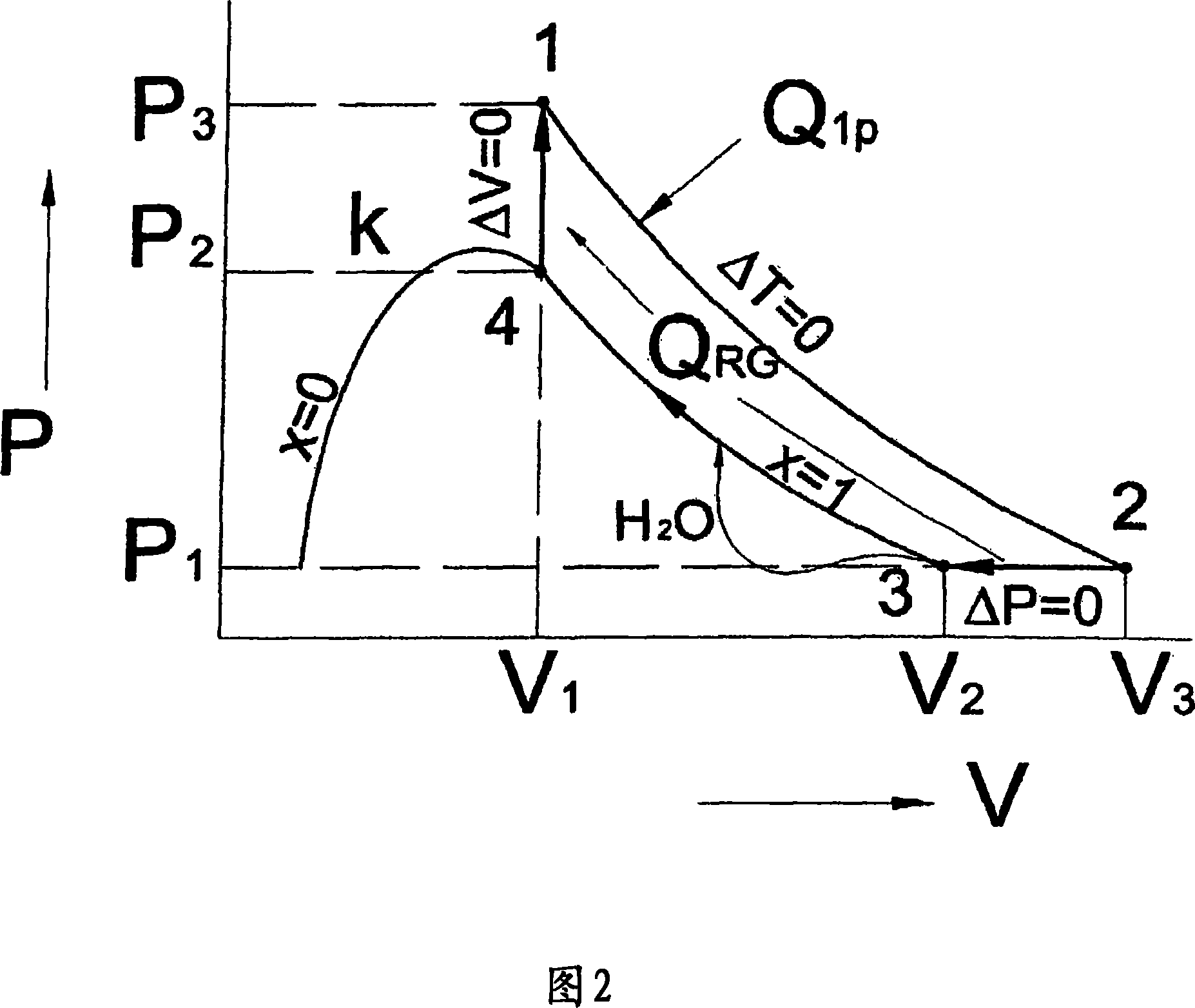

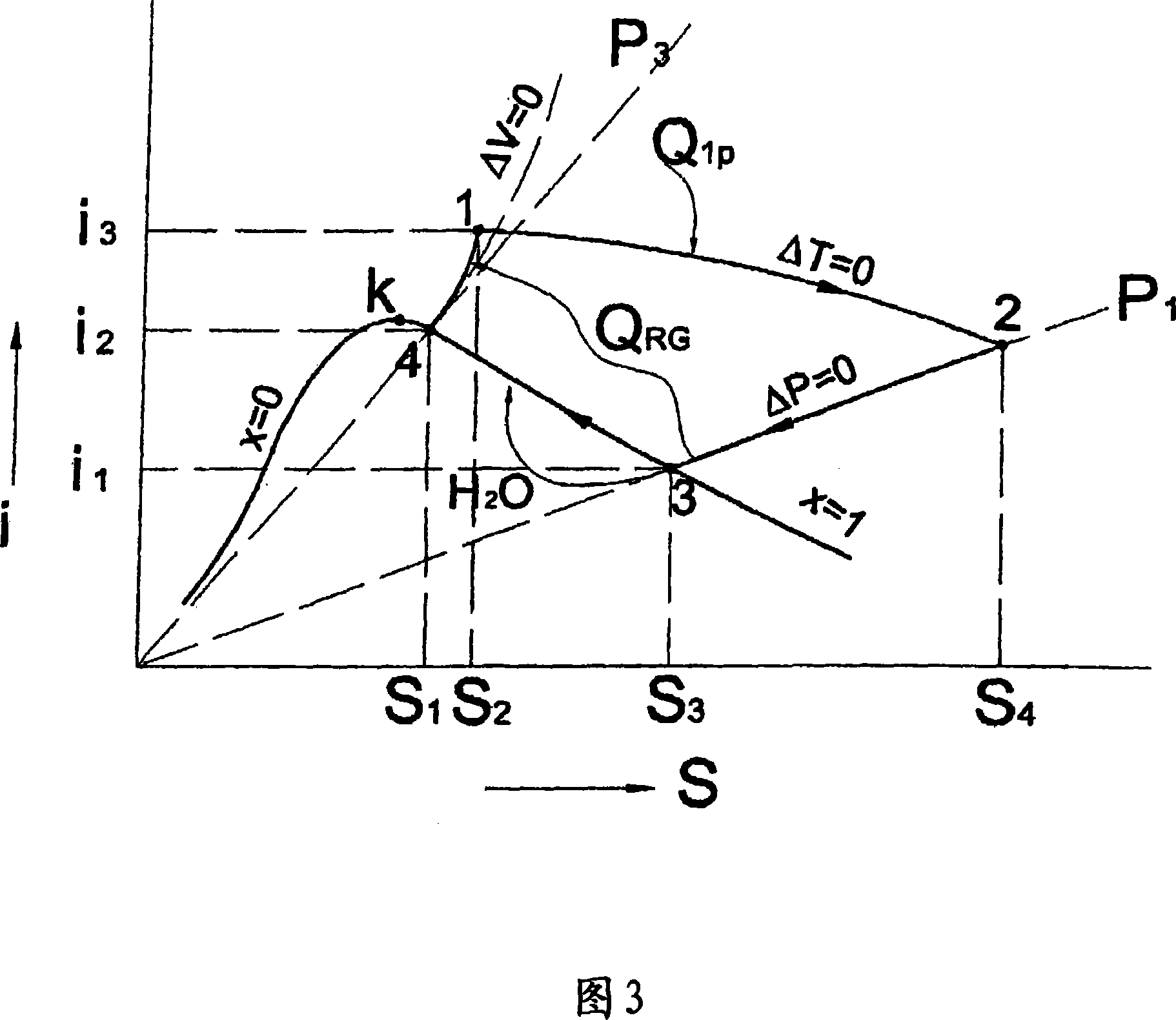

[0022] The principle of the invention will now be explained in detail by explaining the invention based on a thermodynamic steam cycle process, an example of which is illustrated in the accompanying drawings. The examples mentioned here are intended to explain the present invention but not to limit the present invention in any way.

[0023] According to the present invention and its embodiments, an initial flux of a dry saturated steam working medium is generated which, without changing its state of aggregation, undergoes a steam power cycle in the single-phase region. In the compression stage of the vapor working fluid, some part of the working fluid in the liquid state will be additionally injected into the compression chamber, and the injected working fluid will be completely evaporated in the compression chamber, and the heating of the working fluid will be removed under compression . The amount of injected liquid working medium is preferably adjusted at regular intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com