Pressure drum for water purifier and its production

A technology of water purification equipment and production process, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high equipment cost, complex production process, pressure barrel pollution, etc. The appearance is smooth, the process is simple, and the hygienic effect is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

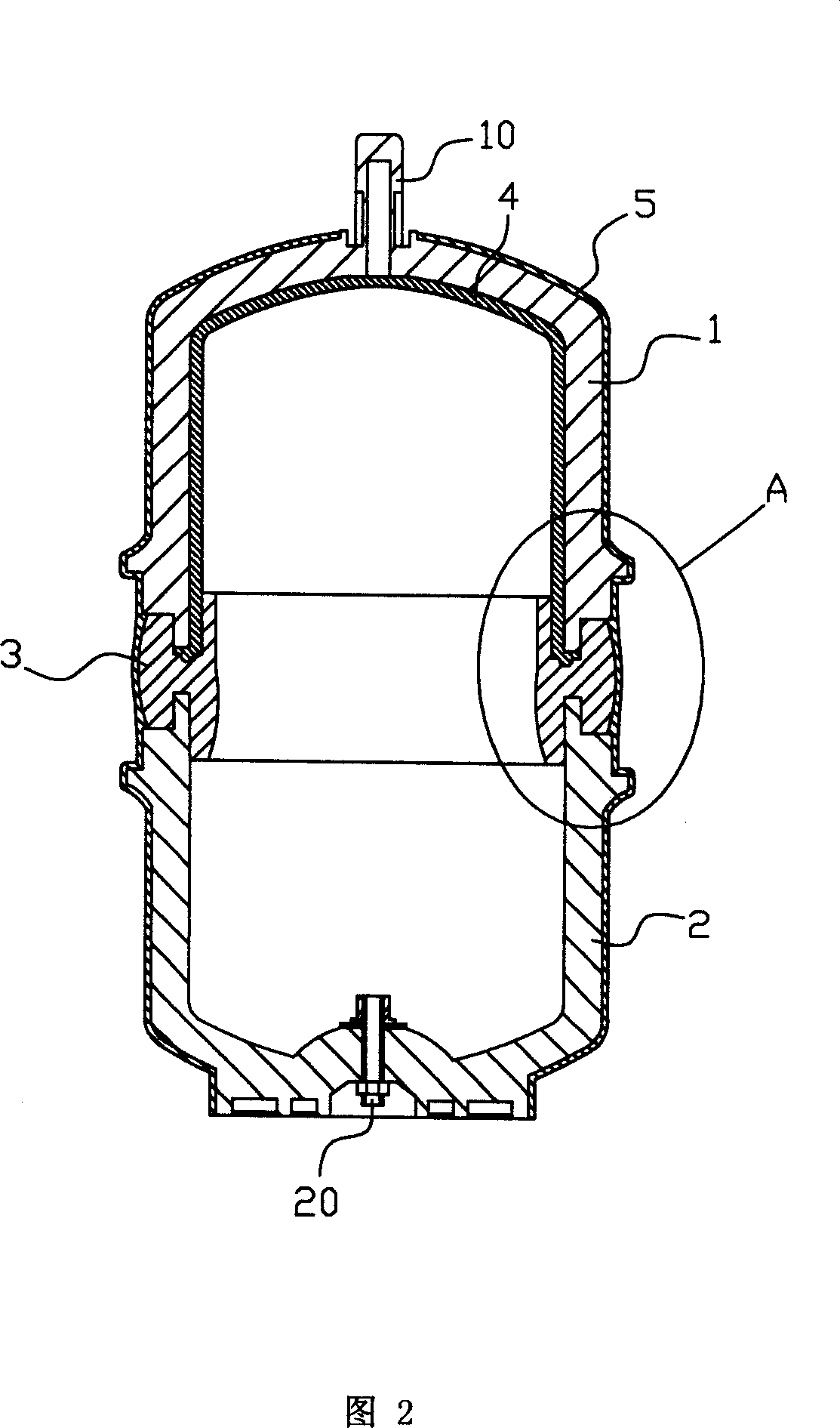

[0020] A specific embodiment of the present invention will be described below with reference to FIGS. 1 to 4 .

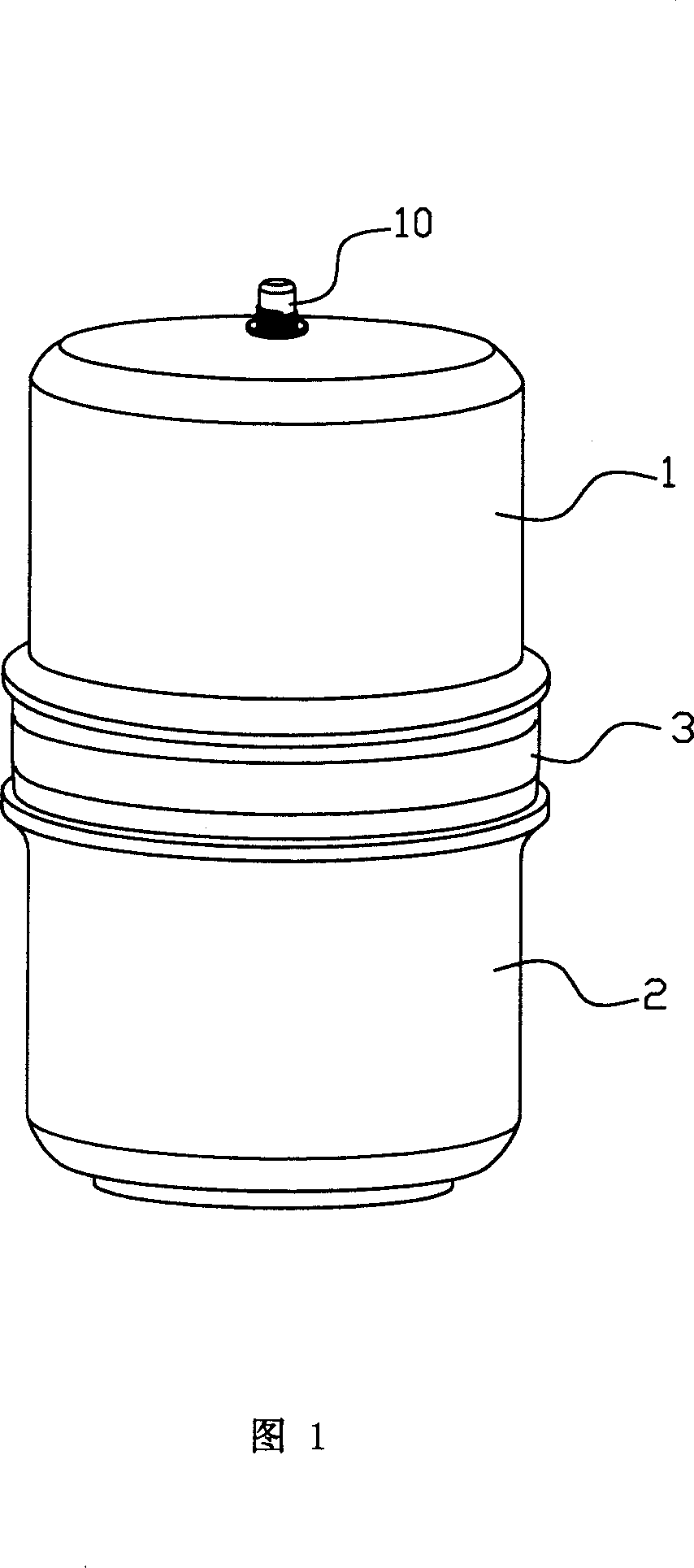

[0021] Referring to Fig. 1, the pressure barrel used for water purification equipment in this embodiment includes an upper half barrel body 1 and a lower half barrel body 2 with openings docked with each other, and the upper half barrel body 1 and the lower half barrel body 2 are connected by a ring The part 3 is connected, and the top of the upper half barrel body 1 is provided with a water inlet and outlet 10 .

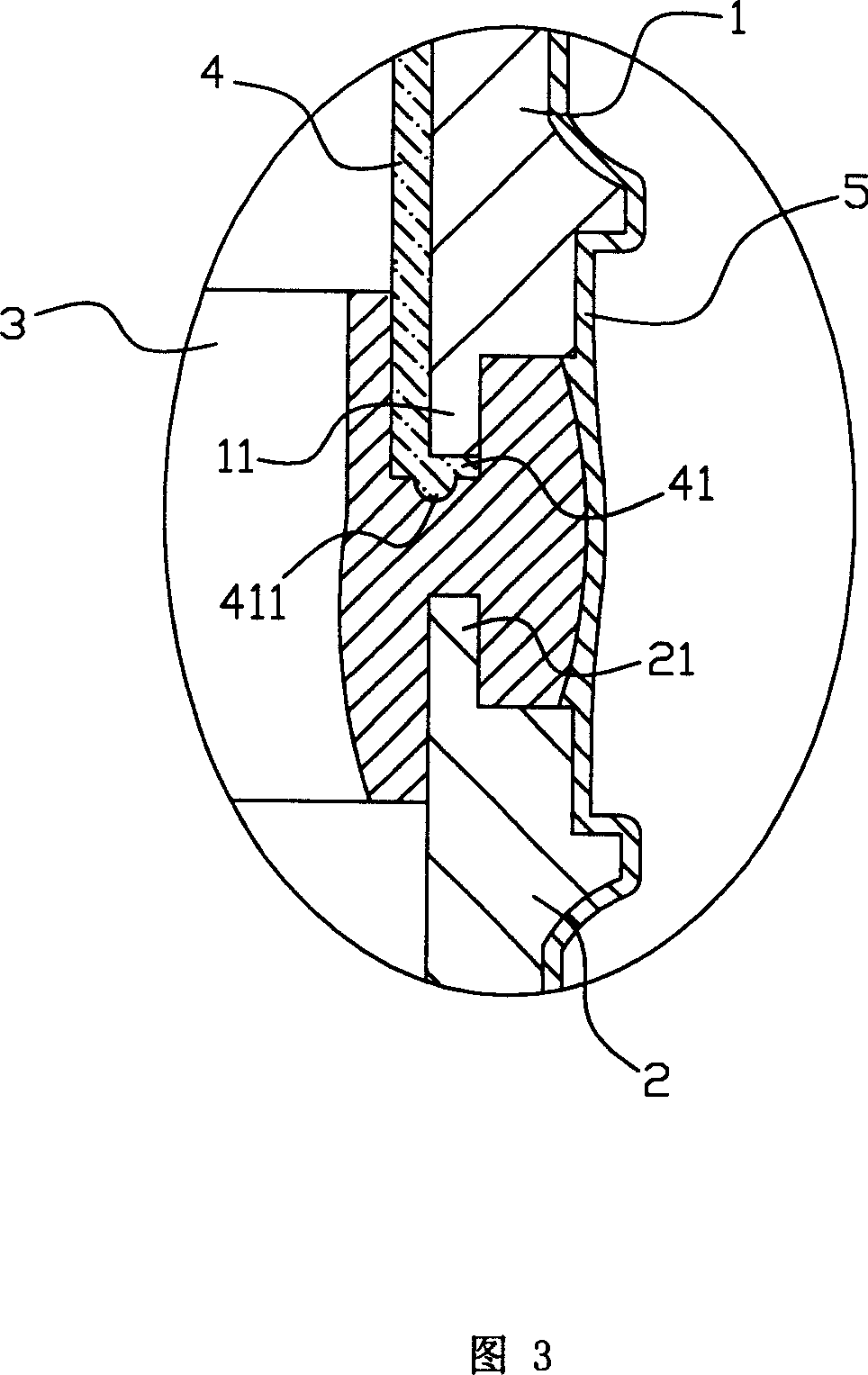

[0022] Referring to Fig. 2 to Fig. 4, the upper end surface of the annular connector 3 is provided with an annular groove 31 in which the periphery of the upper half barrel body 1 can be embedded, and the lower end surface is provided with an annular groove 32 in which the periphery of the lower half barrel body 2 can be embedded. . A stepped surface is formed on the outer side of the bottom periphery of the upper half barrel body 1, and the smaller part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com