Mask and equipment containing mask

A mask and equipment technology, applied in the field of liquid crystal display panel manufacturing process, can solve the problem that the mask affects the efficiency of the machine, and achieve the effect of reducing the type and quantity of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

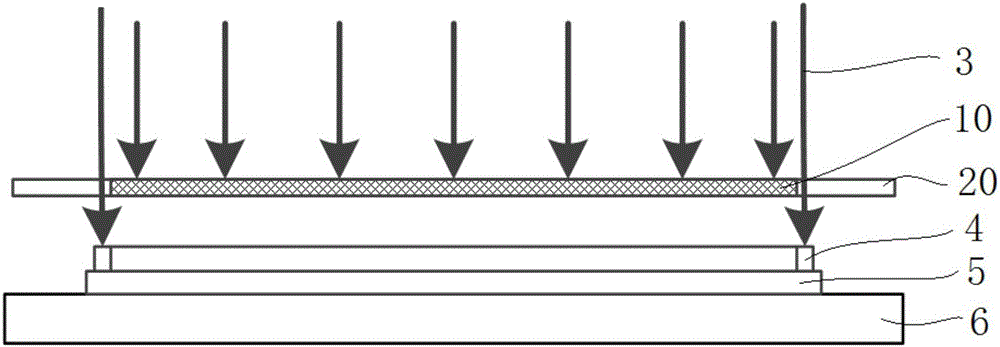

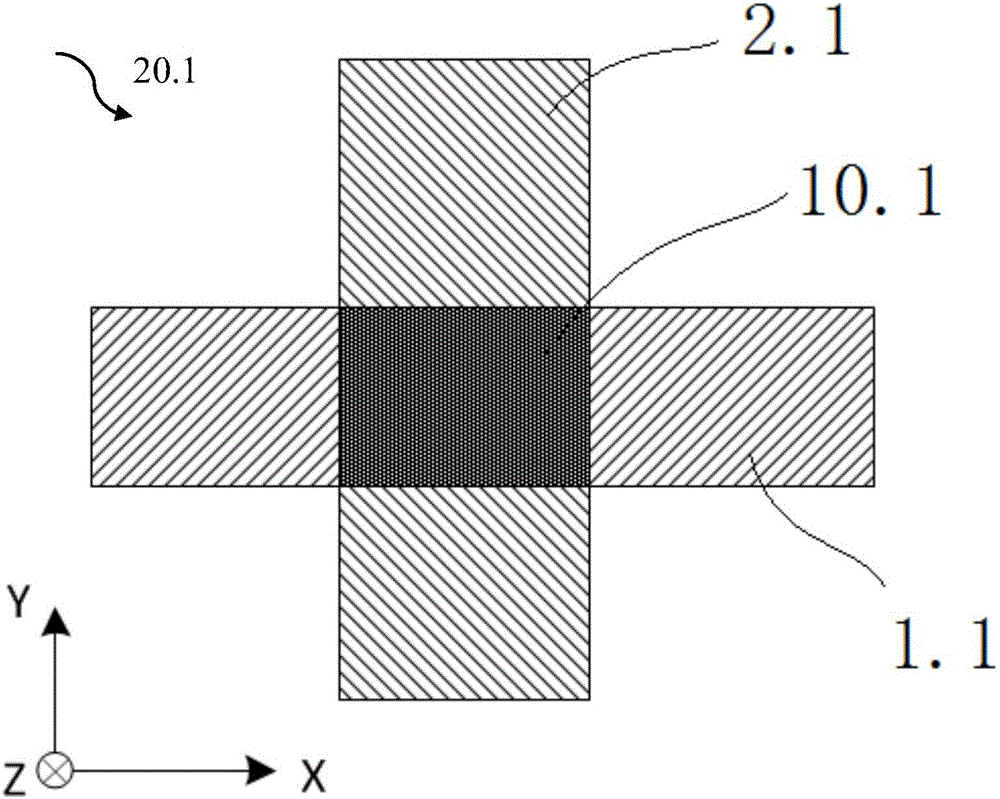

[0037] figure 2 It is a schematic diagram of the mask 20.1 of the first embodiment of the present invention, the mask 20.1 includes an X polarizer 1.1 and a Y polarizer 2.1, and the polarization direction of the X polarizer 1.1 is perpendicular to the polarization direction of the Y polarizer 2.1, and the X polarizer The X plane to which sheet 1.1 belongs is parallel to the Y plane to which Y polarizer 2.1 belongs. The angle between the direction and the Y direction is greater than 0 degrees, and the normal direction of the X plane or the Y plane is defined as the Z direction. When observing along the Z direction, the X polarizer 1.1 overlaps the Y polarizer 2.1, and the X polarizer is set The overlapping area of sheet 1.1 and Y polarizing sheet 2.1 is the first overlapping area 10.1. Since X polarizing sheet 1.1 and Y polarizing sheet 2.1 have the same polarization direction, the polarized light passing through X polarizing sheet 1.1 cannot pass through Y polarizing sheet ...

Embodiment 2

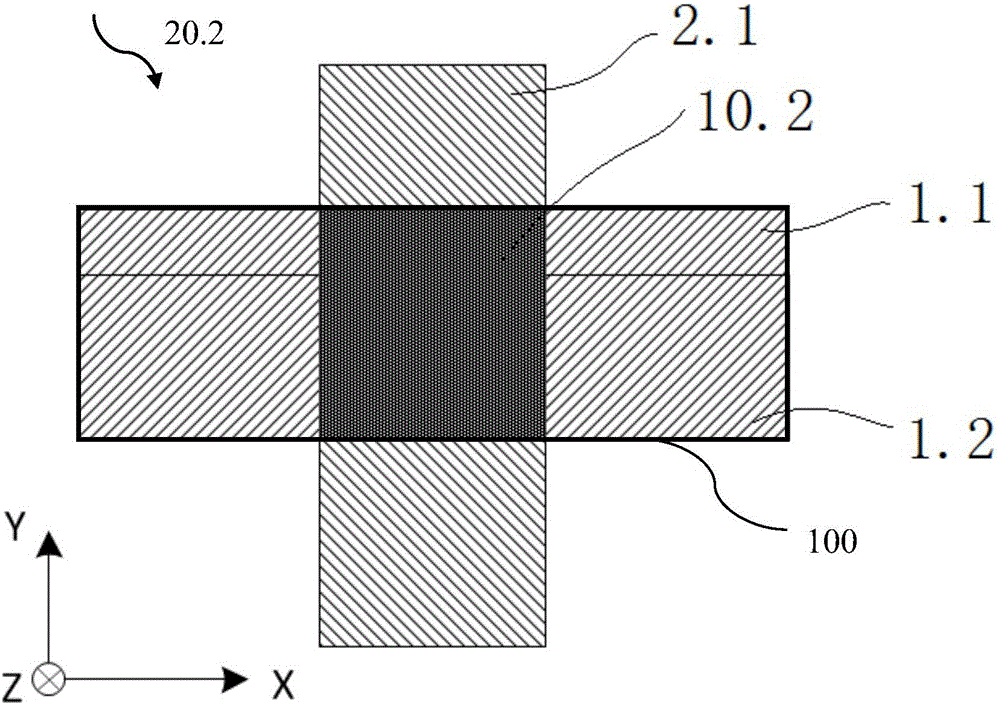

[0039] On the basis of the first embodiment, when the width of the liquid crystal region along the Y direction on the substrate of the sealant to be cured is greater than the width of the X polarizer 1.1 along the Y direction, multiple X polarizers can be arranged along the Y direction as required. polarizer. Such as image 3 It is a schematic diagram of the mask 20.2 of the second embodiment. At this time, the width of the liquid crystal region 10.2 on the substrate along the X direction matches the width of a Y polarizer 2.1 along the X direction, but the width of the liquid crystal region 10.2 along the Y direction The width is greater than the width of X polarizer 1.1 along the Y direction, but smaller than the width of the two X polarizers along the Y direction, so two X polarizers are set in the mask 20.2, namely X polarizer 1.1 and X polarizer 1.2.

[0040] Such as image 3 , the X polarizer 1.1 and the X polarizer 1.2 are arranged in parallel in different planes, the...

Embodiment 3

[0044] On the basis of the second embodiment, when the width of the liquid crystal region along the X direction of the substrate of the sealant to be cured is greater than the width of the Y polarizer 2.1 along the X direction, multiple Y polarizers can be set along the X direction as required piece. Such as image 3 It is a schematic diagram of the mask 20.3 of the third embodiment. At this time, the width of the liquid crystal region 10.3 on the substrate along the X direction is greater than the width of the Y polarizer 2.1 along the X direction, but smaller than the width of the two Y polarizers along the X direction , so two Y polarizers are set in the mask 20.3, that is, Y polarizer 2.1 and Y polarizer 2.2.

[0045] Such as Figure 4 , the Y polarizer 2.1 and the Y polarizer 2.2 are arranged in parallel in different planes, the Y polarizer 2.1 and the Y polarizer 2.2 are respectively arranged along the Y direction in the plane, and observed along the Z direction, the Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com