Oxygen vacancy lithium titanate composite material and preparation method thereof and lithium titanate battery

A technology of composite materials and lithium titanate, which is applied in titanate, titanium compounds, secondary batteries, etc., can solve the problems of harsh process, difficult to form stable and uniform materials, and difficult conductive materials, so as to achieve simple and environmentally friendly process, The effect of improving the conductivity and increasing the charge-discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

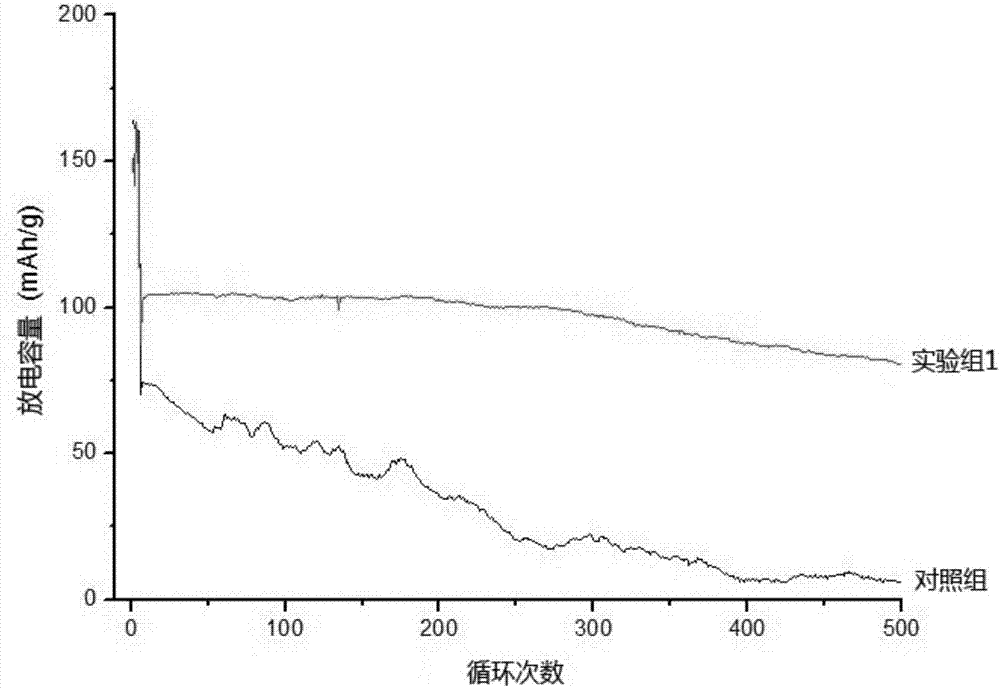

Embodiment 1

[0026] Example 1, a method for preparing an oxygen-deficient lithium titanate composite material, the method comprising: placing pure lithium titanate or lithium titanate doped with metal element M in a mixed gas atmosphere of an organic gas and an inert gas In 1000°C, heat for 5 minutes and cool to obtain an oxygen-deficient lithium titanate composite material;

[0027] The metal element M is selected from at least one of iron, cobalt, nickel, molybdenum, zirconium, copper, zinc, magnesium, aluminum, silicon, and rare earth elements;

[0028] The organic gas is one of alkanes, alkenes, alkynes or gaseous alcohols with seven carbon atoms or less, and the organic gas accounts for 5% of the total volume of the mixed gas.

Embodiment 2

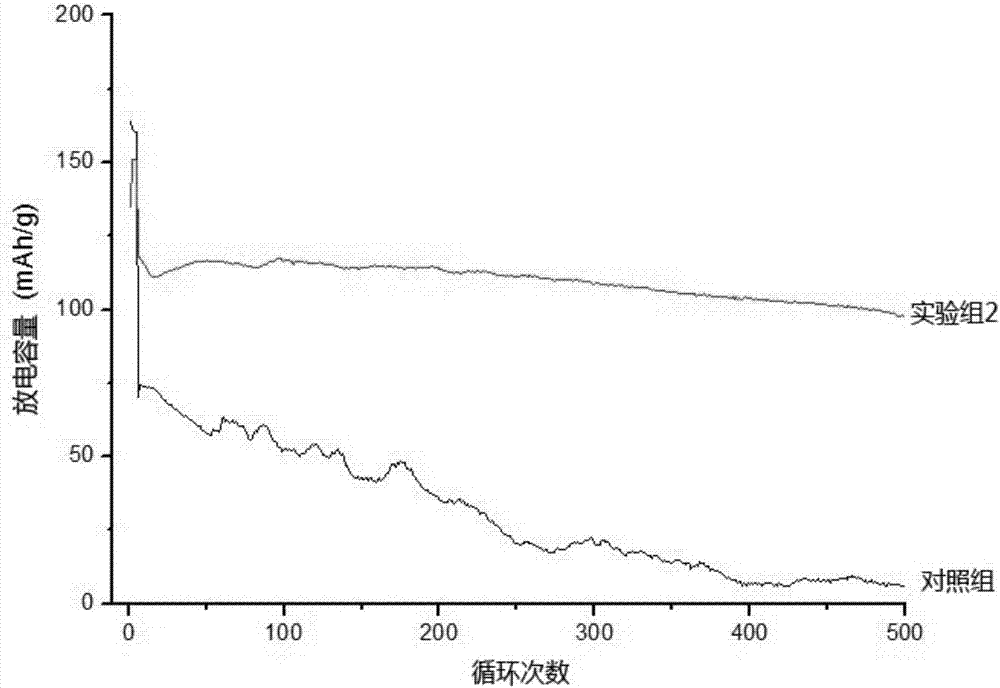

[0029] Example 2, a method for preparing an oxygen-deficient lithium titanate composite material, the method comprising: placing pure lithium titanate or lithium titanate doped with metal element M in a mixed gas atmosphere of organic gas and inert gas , heat preservation at 700°C for 24 hours, and cool to obtain an oxygen-deficient lithium titanate composite material;

[0030] The metal element M is selected from at least one of iron, cobalt, nickel, molybdenum, zirconium, copper, zinc, magnesium, aluminum, silicon, and rare earth elements;

[0031] The organic gas is one of alkanes, alkenes, alkynes or gaseous alcohols with seven carbon atoms or less, and the organic gas accounts for 95% of the total volume of the mixed gas.

Embodiment 3

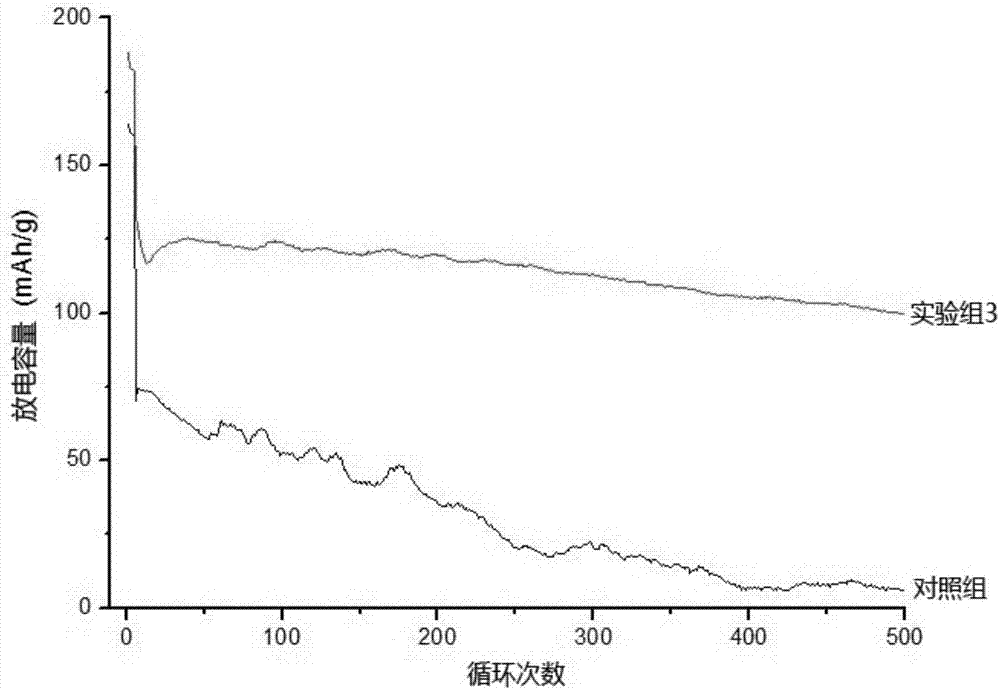

[0032] Example 3, a method for preparing an oxygen-deficient lithium titanate composite material, the method comprising: placing pure lithium titanate or lithium titanate doped with metal element M in a mixed gas atmosphere of organic gas and inert gas , heat preservation at 850°C for 12 hours, and cool to obtain an oxygen-deficient lithium titanate composite material;

[0033] The metal element M is selected from at least one of iron, cobalt, nickel, molybdenum, zirconium, copper, zinc, magnesium, aluminum, silicon, and rare earth elements;

[0034] The organic gas is one of alkanes, alkenes, alkynes or gaseous alcohols with seven carbon atoms or less, and the organic gas accounts for 40% of the total volume of the mixed gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com