Amorphous magnetic core vertical winding inductor

A technology of inductors and magnetic cores, applied in the field of inductors, can solve the problems of smaller total contact area, poor consistency, and high processing costs, reduce the increase in magnetic core loss, improve consistency, yield, and EMC effects improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] A preferred embodiment of the preparation method of the above-mentioned amorphous magnetic core vertical winding inductor provided by the present invention includes the following steps:

[0040] In the step of cutting the annular amorphous magnetic core, the purchased or self-made annular amorphous magnetic core 20 is loaded into the tooling, and the magnetic core is cut into at least two magnetic core segments along the axial direction of the annular amorphous magnetic core 20; The core section can still be combined into a complete annular amorphous magnetic core after being put on the metal steel strip; in the preferred embodiment of the present invention, the method of cutting with a grinding wheel is adopted in this step, and the thickness of the selected grinding wheel cutting piece is preferably 0.1mm- 2mm, more preferably 0.5-1mm; if the grinding wheel is too thin, it is easy to break inside the magnetic powder core; if the grinding wheel is too thick, the loss of...

Embodiment 1

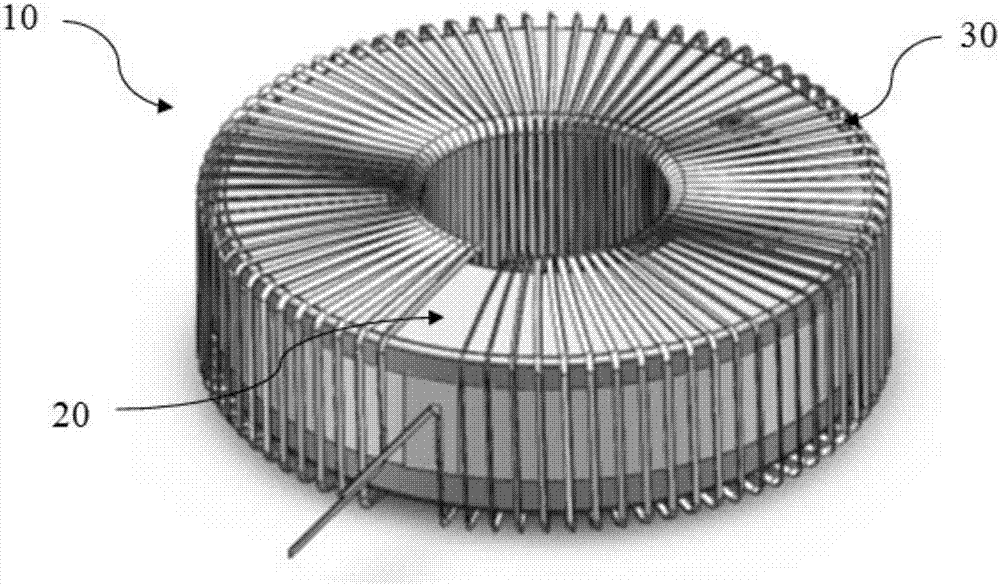

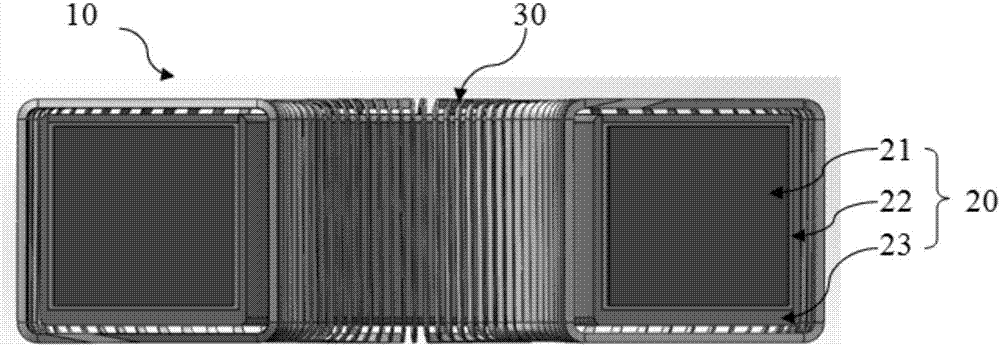

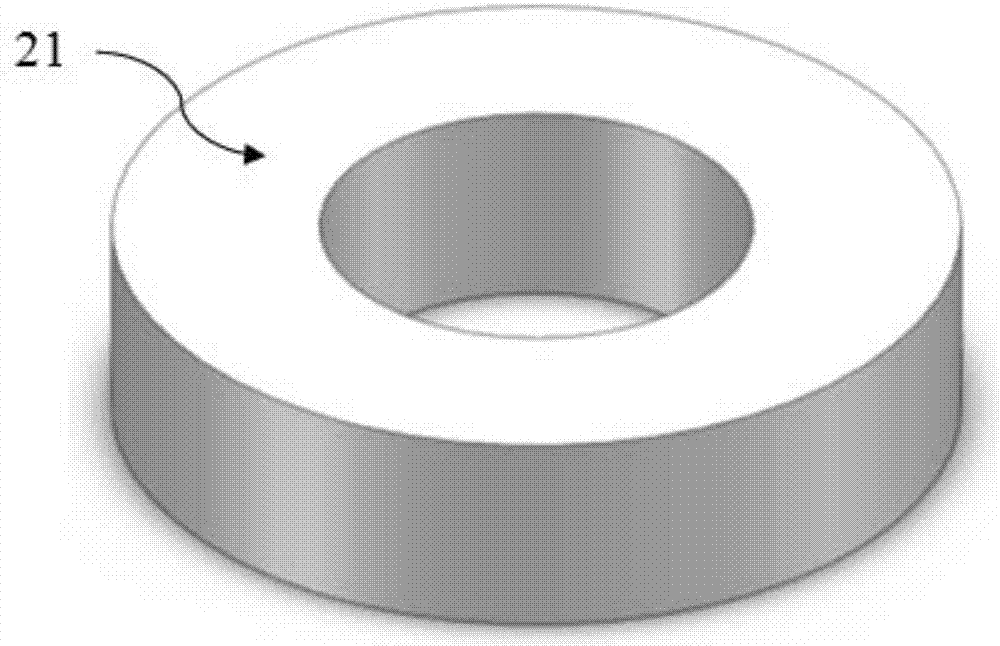

[0045] The vertically wound amorphous core inductor 10 of this embodiment is composed of an annular amorphous core 20 and a flat coil 30 , and the flat coil 30 is vertically wound on the annular amorphous core 20 with 85 turns. More specifically, the annular amorphous magnetic core 20 is Fe 78 Si 9 B 13 (The subscript number of the composition indicates the atomic percentage) The annular amorphous magnetic powder core 21 is put into a plastic sheath 23 and sealed and solidified with a silicone resin 23, and then cut into two magnetic core segments 24 and 25 by a grinding wheel and then combined, wherein, Each magnetic core segment 24, 25 is tightly bound into an annular whole by metal steel bands. figure 1 It is the overall effect diagram of the amorphous magnetic core vertical winding inductor of this embodiment; figure 2 It is a schematic cross-sectional view of the assembled amorphous core vertically wound inductor of this embodiment; image 3 For the Fe-Si-B annular a...

Embodiment 2

[0064] The preparation method of embodiment 2 is the same as that of embodiment 1, except that the number of turns of the vertically wound flat coil is 45 turns. Table 5 shows the inductance characteristic parameters of Embodiment 1 and Embodiment 2. It can be seen from the data in Table 4 that the number of turns decreases, and the inductance attenuation range at 10A is low. The inductance of 85 turns is attenuated to 73.3%, while the inductance of 45 turns is only Attenuation to 95.5%. In practical applications, according to the actual performance requirements, the smaller the number of turns, the better the anti-saturation capability under the condition of satisfying the requirements of the initial inductance performance.

[0065] Table 5 Comparison of installed inductance characteristics between embodiment 1 and embodiment 2

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com