Method and related apparatus for controlling rotation frequency of spindle in optical disc drive

A technology of rotation frequency and spindle, which is applied in the field of controlling the rotation frequency of the spindle of an optical drive, and can solve problems such as increasing the design complexity of the control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

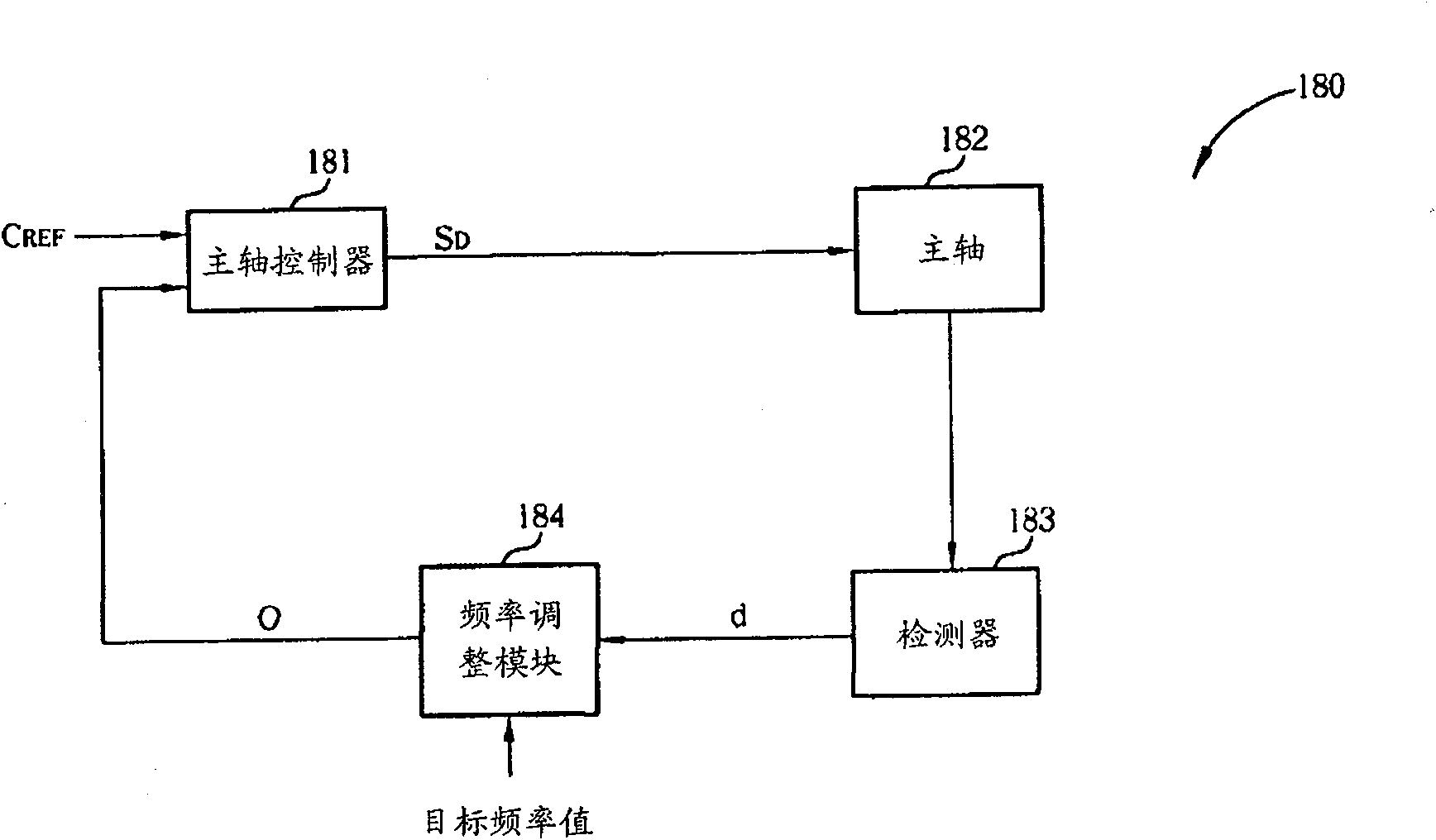

[0068] Please refer to figure 2 , which is a block diagram of a control circuit 180 according to the first embodiment of the present invention. The control circuit 180 is applied in an optical drive, and the optical drive operates in a constant angular velocity mode. The control circuit 180 includes a spindle controller 181 , a spindle 182 , a detector 183 , and a frequency adjustment module 184 . The control circuit 180 compares an output signal O with a reference clock C REF , to generate a drive control signal S D to drive the main shaft 182 to rotate at a predetermined rotational frequency. The detector 183 detects the rotation frequency of the spindle 182 and generates a detection signal d corresponding to the constant surface speed mode. The frequency adjustment module 184 receives a target frequency value, and increases the frequency of the detection signal d. Therefore, the frequency adjustment module 184 outputs an output signal O having the target frequency to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com