Conductive paste and method for manufacturing multilayer printed wiring board using same

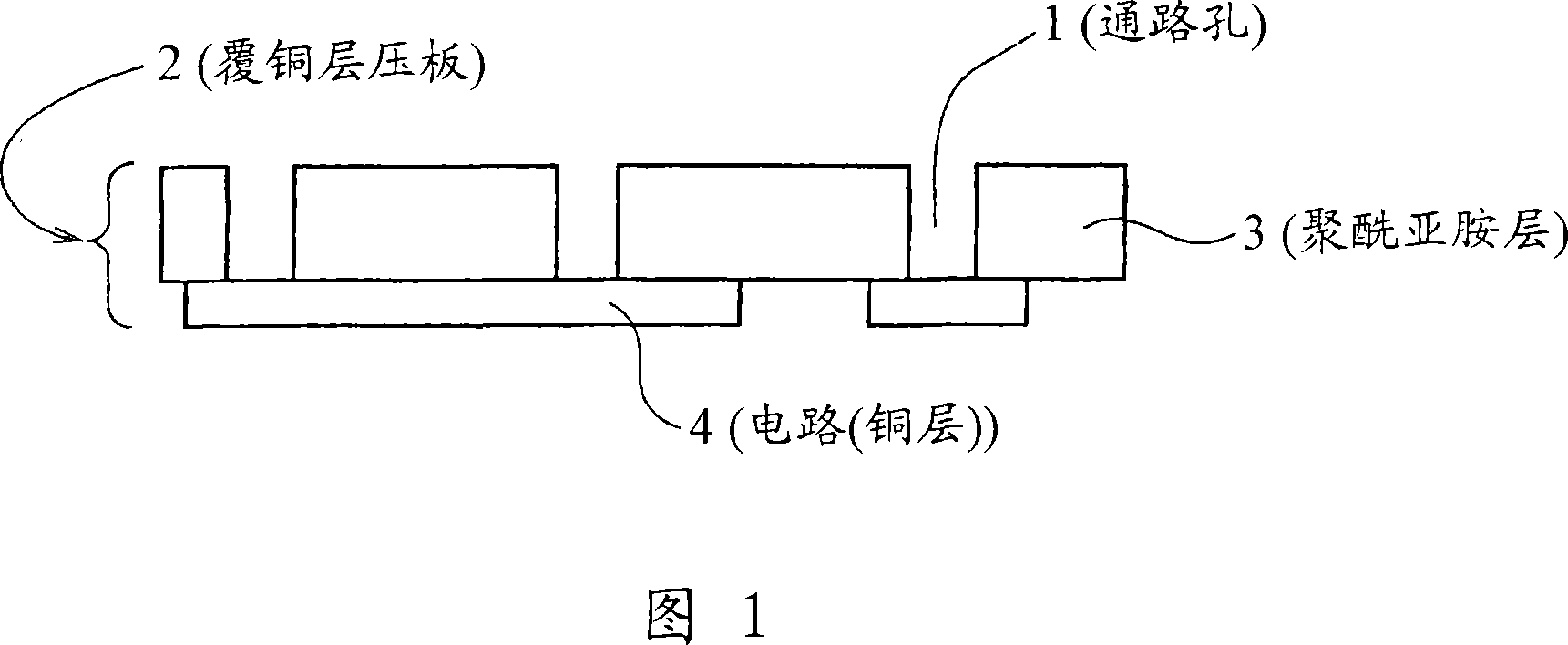

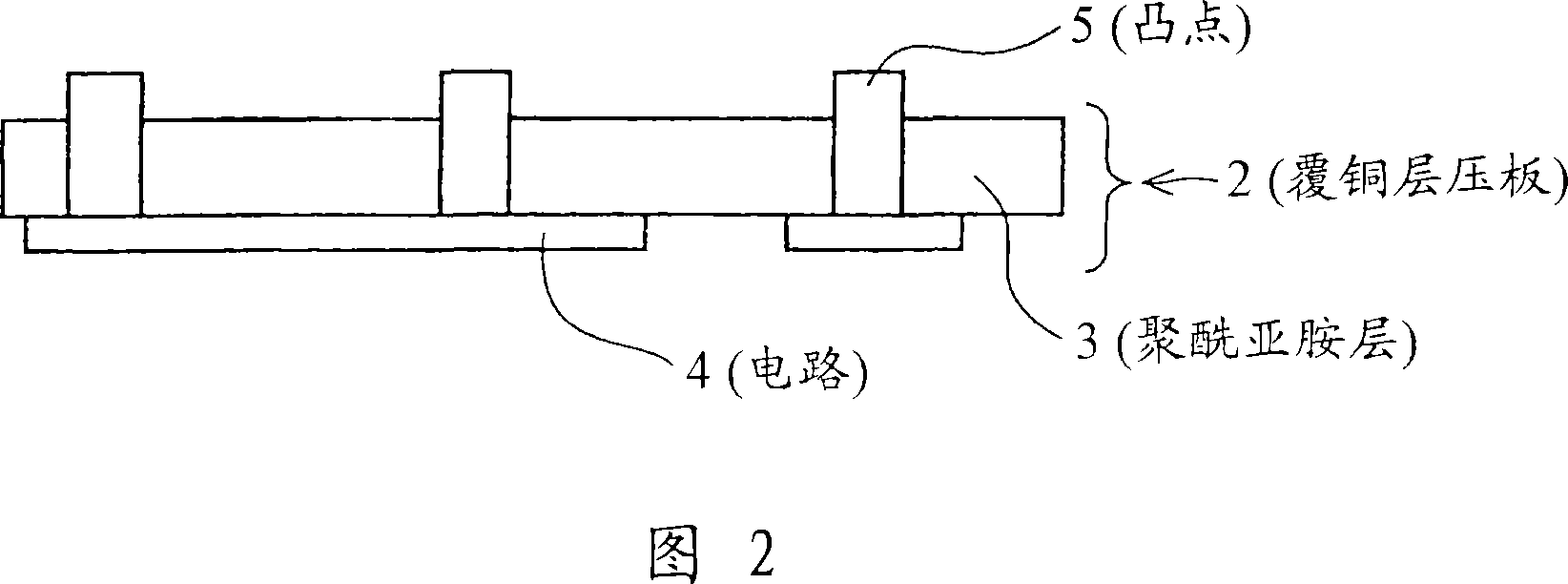

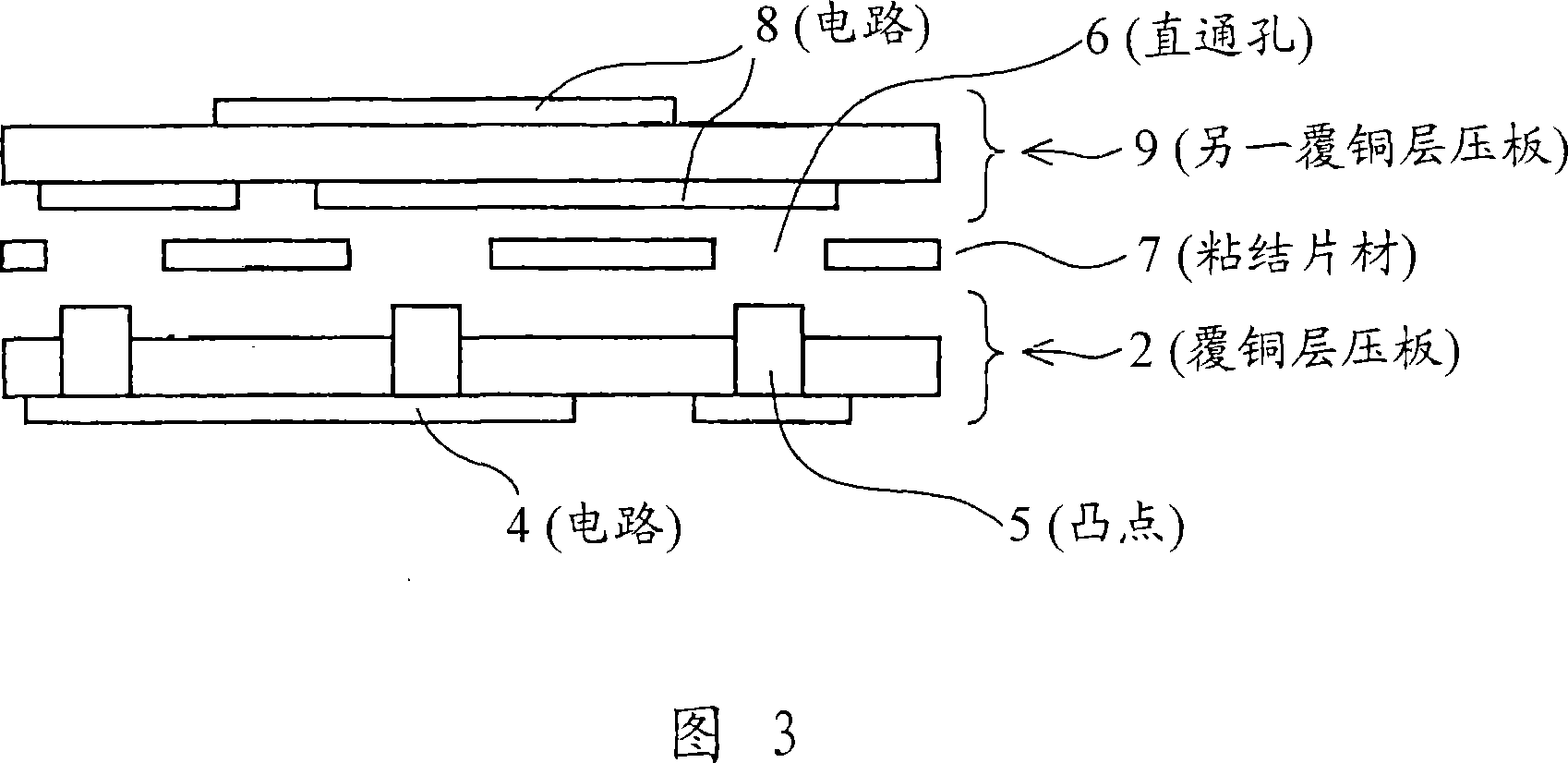

一种导电性、导电层的技术,应用在多层印刷布线板的制造领域,能够解决连接可靠性降低、通路孔填充能力差、通路孔残留气泡等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A plate-like Ag filler with an average particle diameter (50%D) of 4 μm was added to 70% by weight of bisphenol A type resin (high molecular weight type with a molecular weight of 55,000) and 30% by weight of rubber (NBR)-modified epoxy In the resin [EPR4030 manufactured by Asahi Denka Kogyo K.K.], the filler was added in such an amount that the proportion in the conductive paste after hardening was 55% by volume, and butyl carbitol acetate was added thereto as a solvent. All the components were mixed in a three-roll mill, and then an imidazole-based latent hardener was added and mixed to manufacture a conductive paste. At this point, pre-mix bisphenol A type resin (high molecular weight type with a molecular weight of 55,000) and butyl carbitol acetate, and then add rubber (NBR) modified epoxy resin [epoxy equivalent: 380g / eq ]Wait.

Embodiment 2

[0075]A conductive paste was prepared in the same manner as in Example 1, except that bisphenol F type epoxy resin [Epicoat 806 manufactured by Japan Epoxy Resin K.K., epoxy equivalent: 160-170 g / eq] was used instead of rubber (NBR) - Modified epoxy resin.

Embodiment 3

[0077] A conductive paste was prepared in the same manner as in Example 1, except that a naphthalene difunctional epoxy resin [HP4032 manufactured by Dainippon Ink and Chemicals, Incorporated, epoxy equivalent: 135˜165 g / eq] was used instead of rubber ( NBR) - modified epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com