UV imposition method and device

A master and grid technology, applied in the field of UV imposition method and device of devices, can solve the problems of non-splicing, limited fidelity, low position accuracy, etc., achieve excellent filling ability, high positioning accuracy, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0048] Such as Picture 12 As shown, the UV imposition method of the present invention includes the following steps:

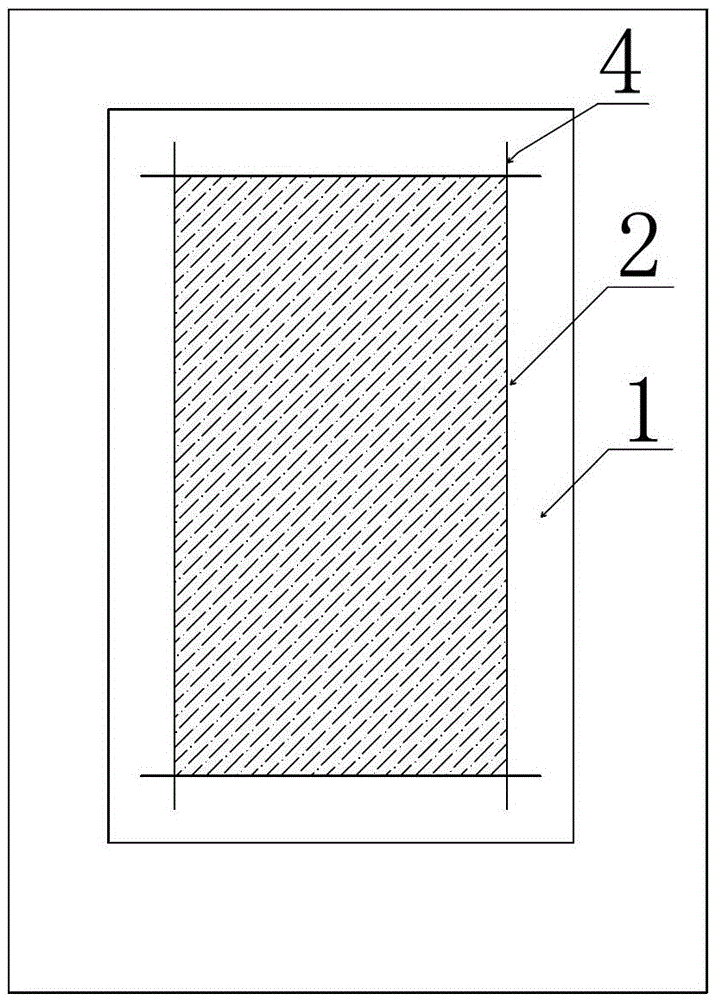

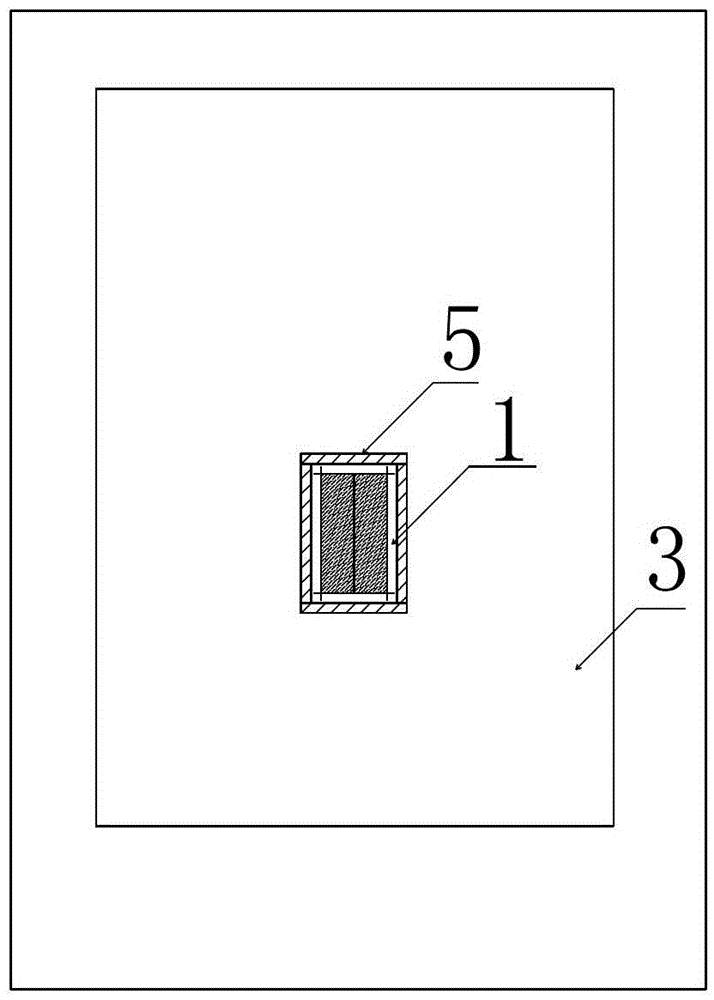

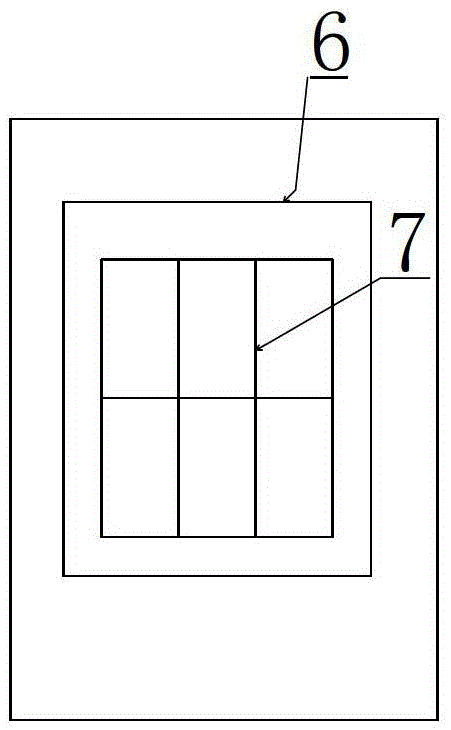

[0049] Step 1: Prepare a unit pattern master 1 for imposition. The size of the unit pattern master 1 is not limited. The unit pattern master 1 has the required splicing pattern 2, and the splicing pattern 2 is a hologram or has The optical structure of the deep groove is about 30-40 microns thick, and the alignment cross marks 4 are made at the four corners of the required splicing pattern 2. This mark line can be made by photolithography or drawn with fine needles. Cell graphics master 1 such as figure 1 As shown, the shape of the puzzled figure can be any shape such as square, rectangle, triangle, prism, trapezoid, hexagon, etc.; fix the unit pattern master 1 with thin tape 5 on the large glass plate 3, the glass plate 3 For a thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com