A kind of neural unit spherical support and its preparation

A nerve unit and spherical technology, applied in medical science, prosthesis, etc., can solve the problems of not being able to meet the requirements of repair materials in ideal nerve defect areas at the same time, and the three-dimensional scaffold cannot be applied to central nerve defect areas, etc., to achieve rapid recovery of nerve function and promote The effect of quick refactoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

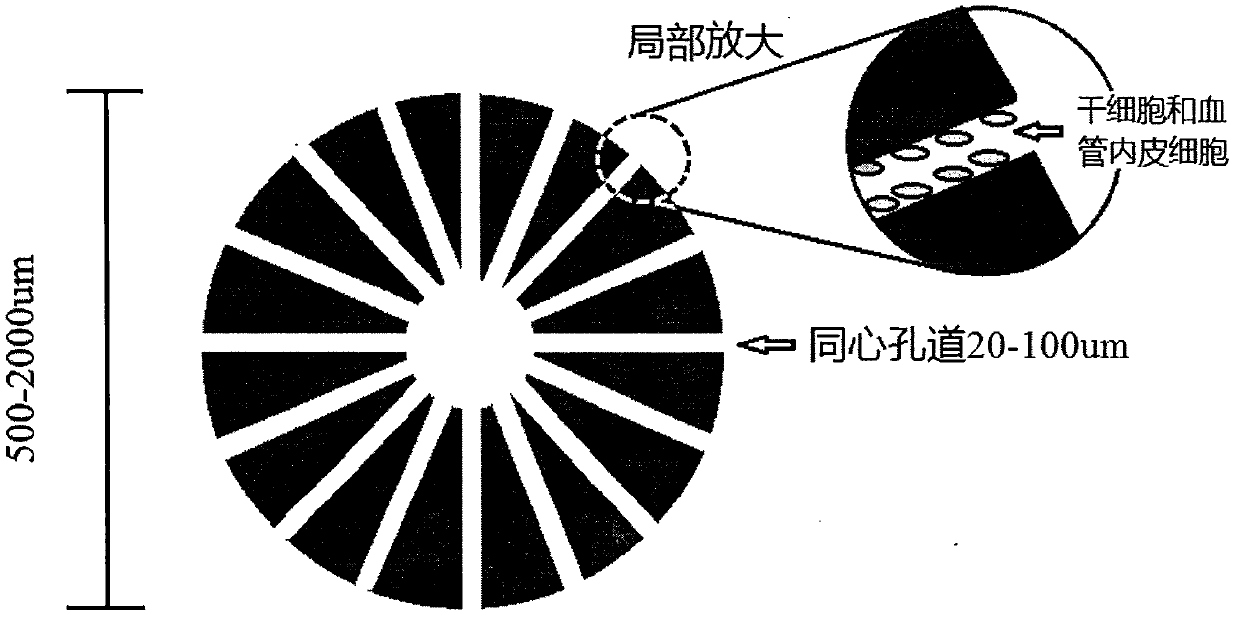

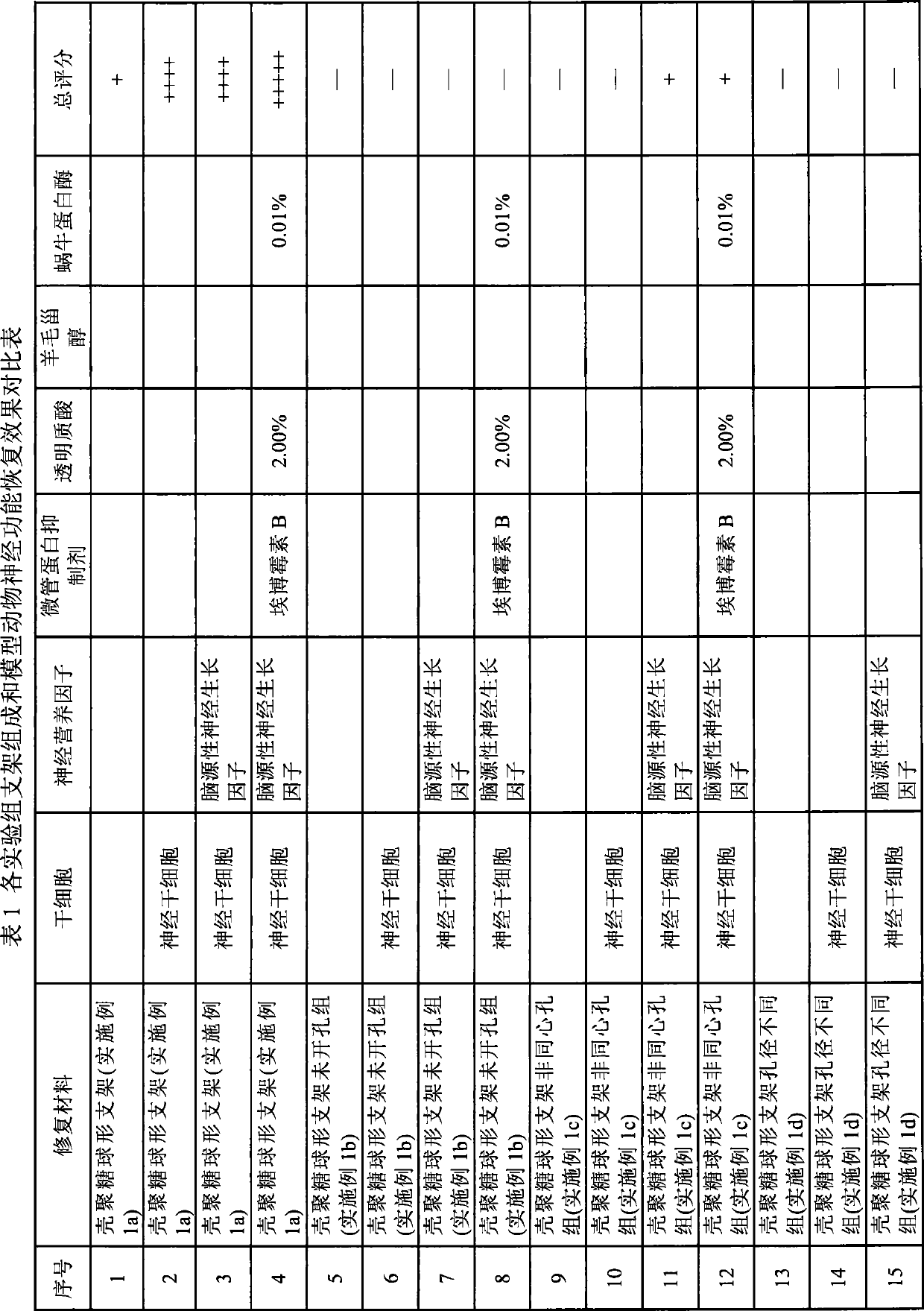

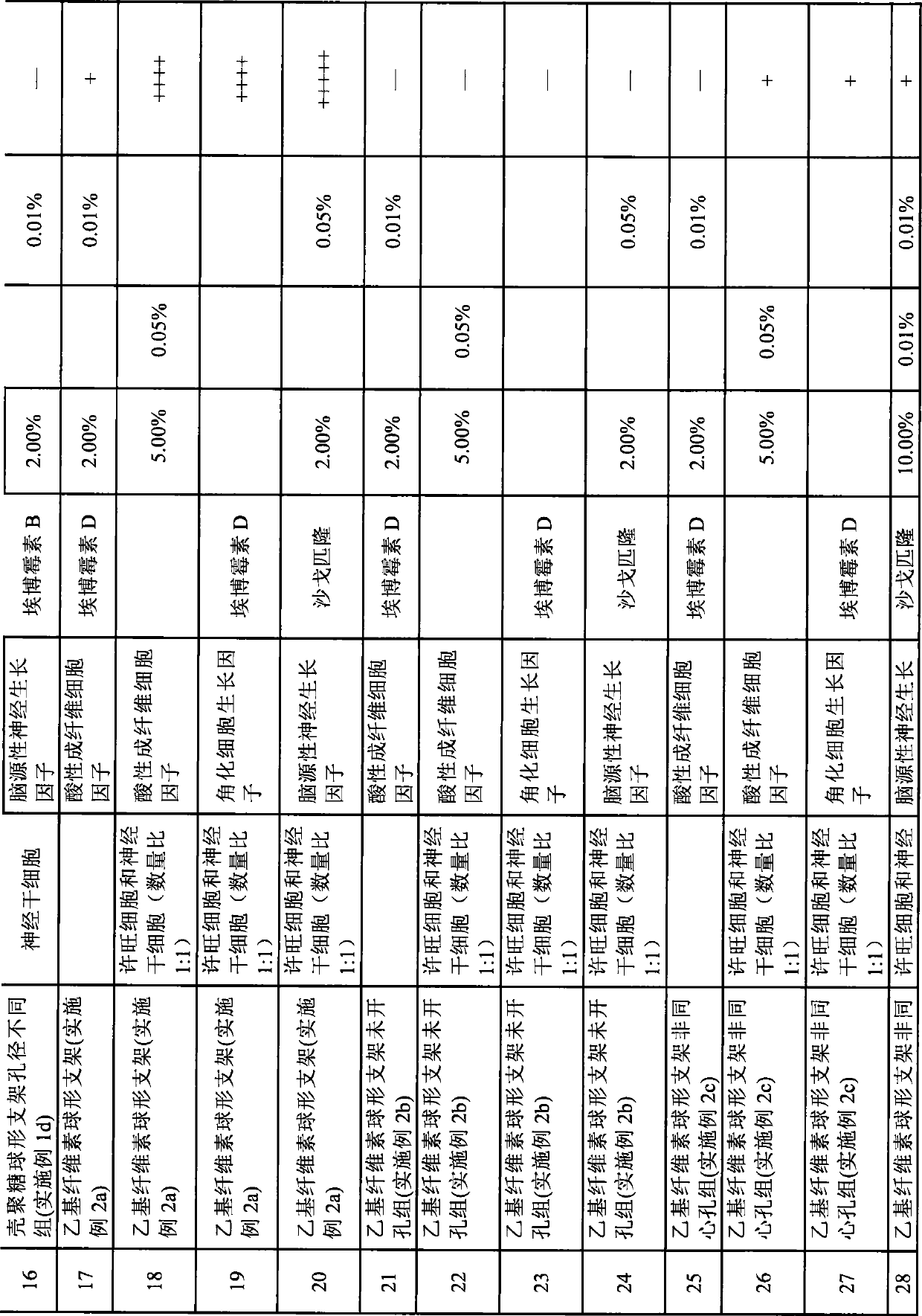

[0024] Example 1 The blank spherical stent prepared by natural polymer material chitosan

[0025] a. Chitosan spherical scaffold

[0026] Get 60mg chitosan (molecular weight 10,000), dissolve in 4ml 3% acetic acid, completely dissolve into a uniform solution. Add 1ml of acetone to it, ultrasonically disperse to form an O / W emulsion, add it to 40ml of liquid paraffin containing 50mg of Span 80: petroleum ether (volume ratio is 1:1), stir and mix at 400 rpm to form O / W / O re-emulsion, drop 0.5ml of glutaraldehyde solution for cross-linking and solidification, continue to stir for 2 hours, centrifuge to separate the microspheres, wash three times with petroleum ether, and naturally evaporate to dry to form chitosan blank hollow microspheres. The surface of chitosan blank microspheres was concentrically punctured with microneedles with a diameter of 100 μm to form a frontal chitosan spherical scaffold with 100 μm pores on the surface and a diameter of 2000 μm.

[0027] The follo...

Embodiment 2

[0031] Example 2 Blank spherical stent prepared from the semi-synthetic polymer material ethyl cellulose

[0032] a. Ethylcellulose spherical scaffold

[0033] Polyvinylpyrrolidone (PVP) and ethylcellulose (EC) were dissolved in 20ml of absolute ethanol, and it was prepared as a mixed solution containing 3.6% polyvinylpyrrolidone and 33% ethylcellulose by mass percent, ultrasonic After uniform dispersion, 4ml of ether was added at 20°C as a dispersed phase solution. Separately prepare 200ml of liquid paraffin containing 50mg of Span 80, slowly add it into the dispersed phase solution at 20°C, stir at 400 rpm, evaporate the organic solvent under ventilated conditions, collect the microspheres by filtration, and dissolve them with n-hexane Washing and vacuum drying to obtain blank hollow microspheres, the surface of which is subjected to concentric perforation with a laser beam to form ethylcellulose spherical scaffolds with 50 μm channels on the surface and a diameter of 1000 ...

Embodiment 3

[0038] Example 3 Blank spherical stent prepared by artificially synthesizing polymer material polyvinyl alcohol

[0039] a. Polyvinyl alcohol spherical bracket

[0040]Prepare 20ml of polyvinyl alcohol (PVA) aqueous solution with a mass percentage of 2%, add 20mg of Span 80, dissolve and mix, add it to 60ml of n-hexane, perform high-speed homogenization to form a W / O emulsion, and add borax saturated aqueous solution drop by drop 20ml, stirred at 300rpm for 3h, separated microspheres after 2h at low temperature, washed 3 times with absolute ethanol, dried in vacuum at 40°C, and the surface was treated with concentric perforation with laser beams to form polyvinyl alcohol spherical scaffolds with 40μn micropores on the surface and a diameter of 800μm .

[0041] The following experimental control groups were prepared in a similar manner:

[0042] b. Non-perforated group: that is, the non-perforated group of polyvinyl alcohol spherical stents obtained without laser beam treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com