Polymer blue dye and application of polymer blue dye in acid copper plating process

An acid electroplating, blue dye technology, applied in the direction of organic dyes, etc., to achieve the effect of improving deep plating ability, strong filling and leveling, and shortening electroplating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means and application methods of the present invention easier to understand, the present invention will be further described below in conjunction with specific embodiments.

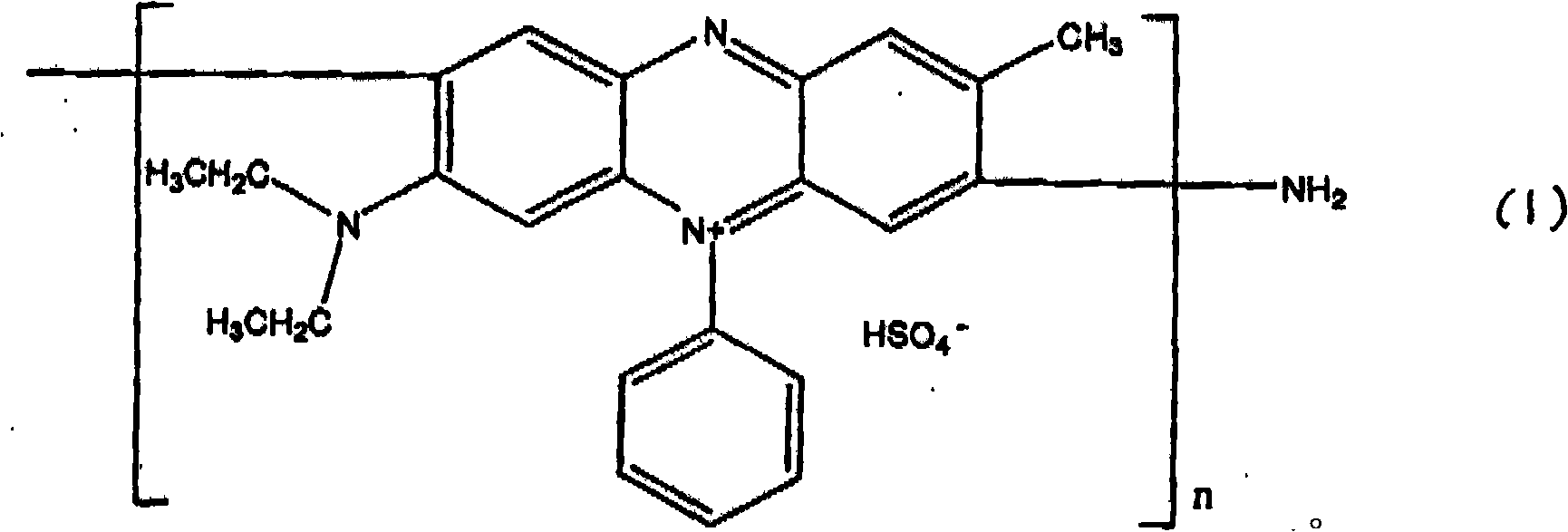

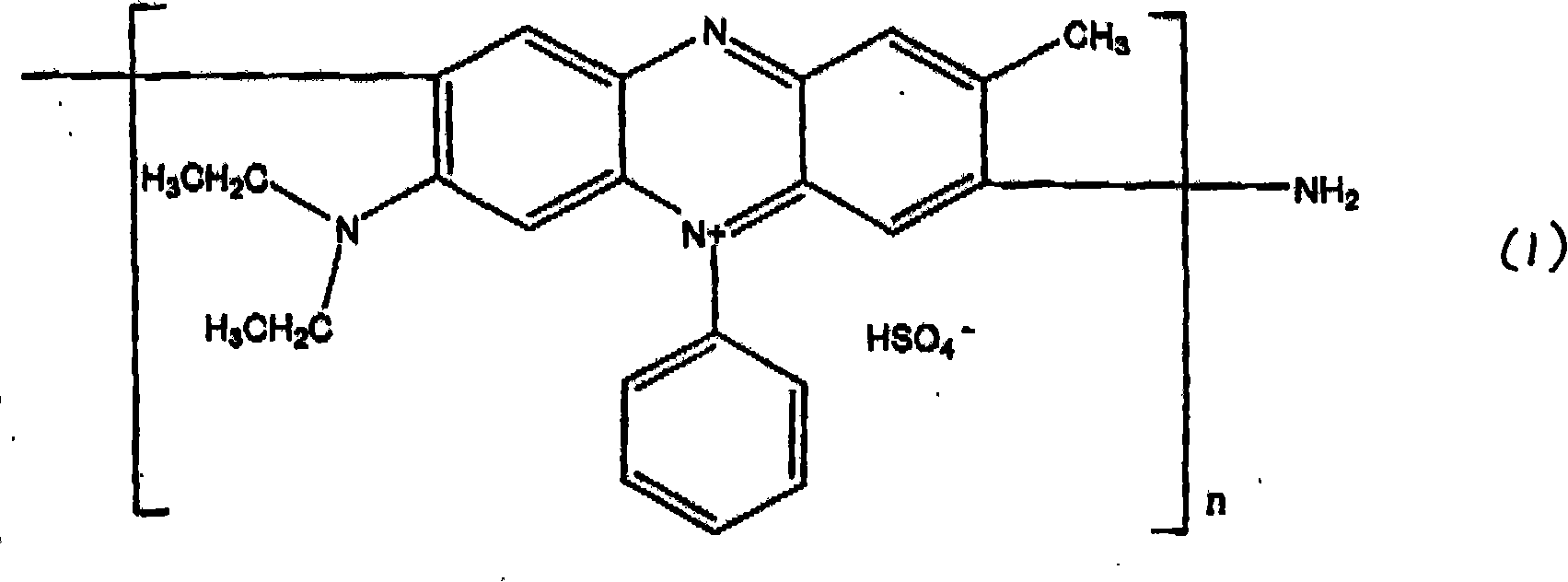

[0016] Polymeric blue dye is the hydrogen sulfate salt of poly(2-methyl-3-amino-5-phenyi-7-(N, N-diethyiamino)phenazine) of formula (1), wherein n is 10

[0017]

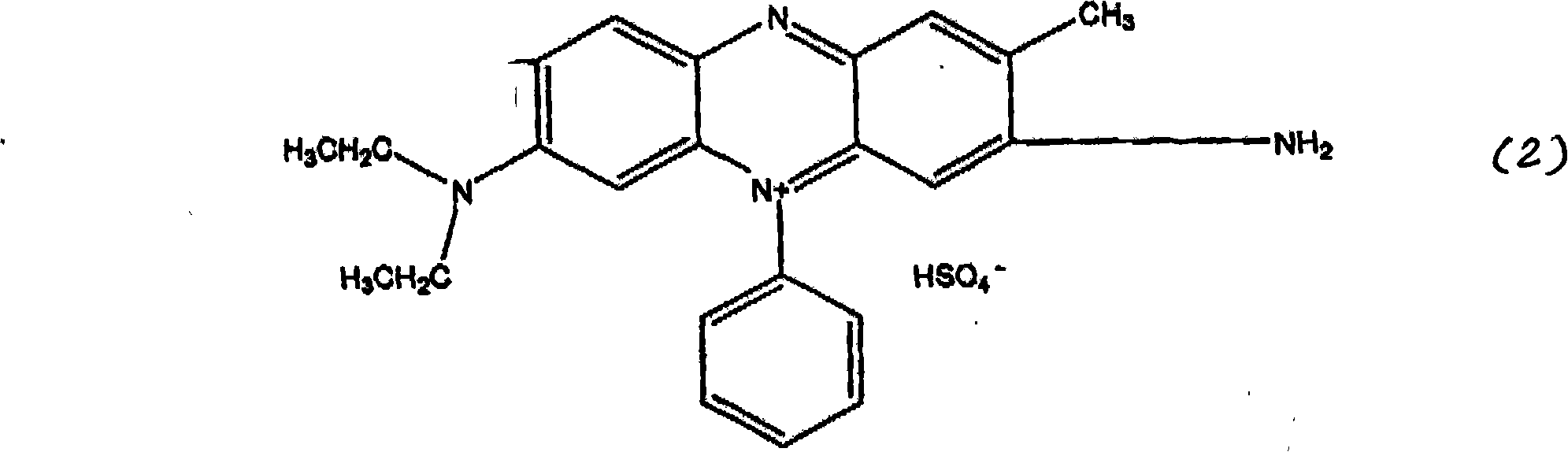

[0018] The preparation method of polymerized blue dye is formed by polymerizing the basic violet 5 dye monomer (Basic Violet5) of formula (2), and the average degree of polymerization is 10

[0019]

[0020] The concentration of the polymerized blue dye in the electroplating solution is between 1.3 mg / L and the temperature is controlled between 10-30°C.

[0021] The polymeric blue dye of this embodiment is used as a leveling agent in the electroplating solution, which can greatly improve the efficiency of the copper electroplating process and shorten the electroplating time, which is 1 / 3-1 / 2 of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com