A kind of partition curing highly filled ab glue, preparation method and application thereof

A curing-type, area-based technology, applied in the direction of adhesives, film/sheet release liners, pressure-sensitive film/sheet, etc., can solve existing problems and problems that cannot be reached, and achieve soft, practical, and reliable arc areas. The effect of processing die-cutting convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

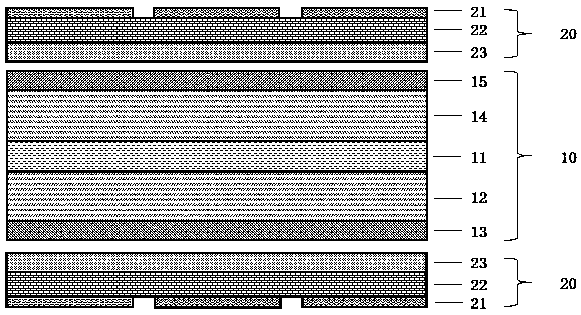

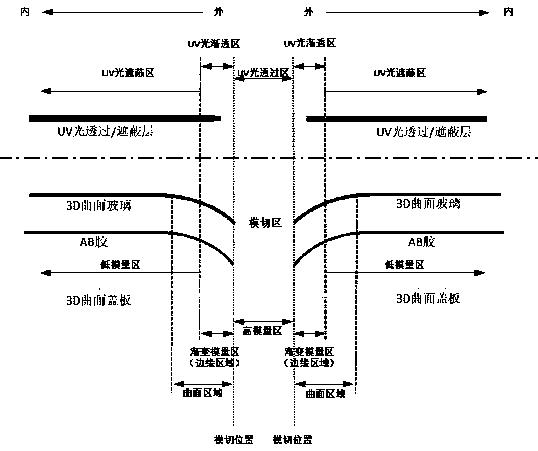

[0035]The technical solutions of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present invention, not all of them. According to the technical solution of the present invention, a partition curing high-filling AB glue 10 is prepared, by removing the PET commonly used in the prior art as the substrate layer, and using an ultra-thin optical film (1-25 μm) as the first substrate layer 11 Instead, through UV partition curing to ensure the balance between the relatively high modulus of the die-cut area and the relatively low modulus (with micro-fluidity) of the curved surface area corresponding to the 3D curved surface cover plate, through the soft silicone pressure-sensitive adhesive Layer 12 has better adhesion to 3D curved cover plates (such as AF glass, etc.), so that the partition curing high-filling AB glue 10 of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com