Ultraviolet sterilizer with water port equipped at two ends of disinfection cavity

An ultraviolet ray and disinfection chamber technology, applied in the direction of light water/sewage treatment, discharge lamps, electrical components, etc., can solve the problems of low pressure tolerance of the disinfection chamber, reduce the disinfection effect, reduce the radiation dose, etc., to improve the disinfection effect, Increases UV radiation dose and reduces resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

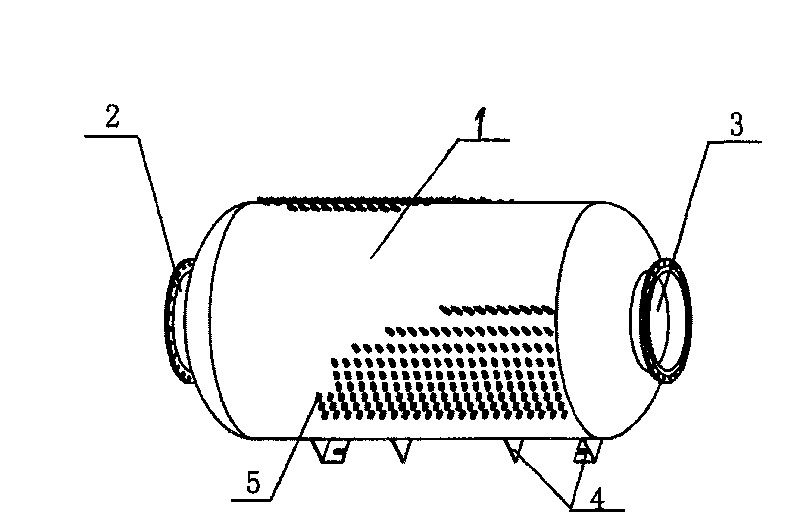

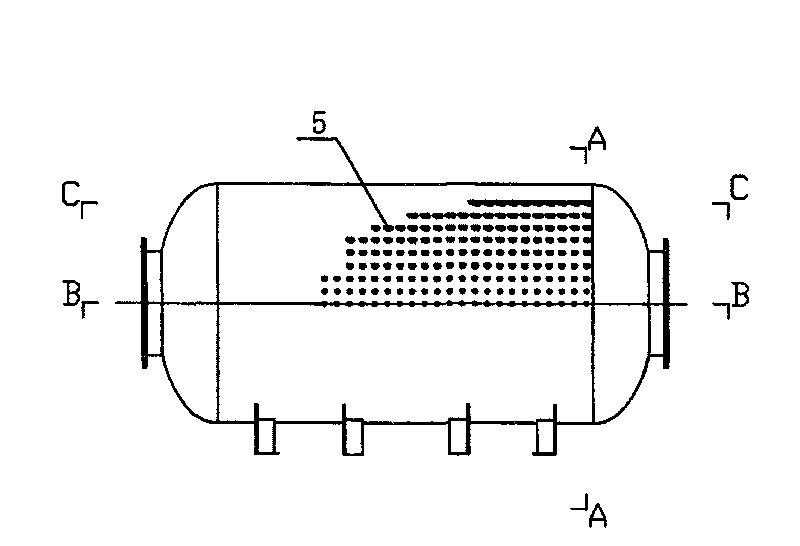

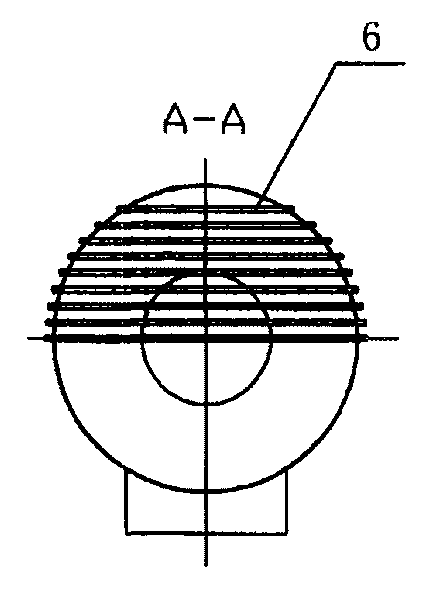

[0017] like Figure 1-5 As shown in , 1 is the ultraviolet disinfection chamber, 2 and 3 are the water outlets of the disinfection chamber, 4 is the foot of the disinfection chamber, 5 is the hole seat for the ultraviolet lamp tube, and 6 is the ultraviolet lamp tube.

[0018] The cavity 1 of the ultraviolet sterilizer is a cylinder with openings at both ends. The main cavity is cylindrical. The openings at both ends of the main cavity are used as two water outlets 2 and 3, which are respectively used as the water inlet and outlet of the sterilizer. Nozzle, set foot 4 under the cylinder of the sterilizer to support the ultraviolet sterilizer, and set a lamp tube mounting hole seat 5 at the intersection of a group of planes parallel to the cylinder axis section B-B in the cylinder and the cylinder wall for installing the ultraviolet lamp 6, that is, several ultraviolet lamp tubes are set on each plane parallel to the horizontal axis section, such as figure 2 , 3 , 4, two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com