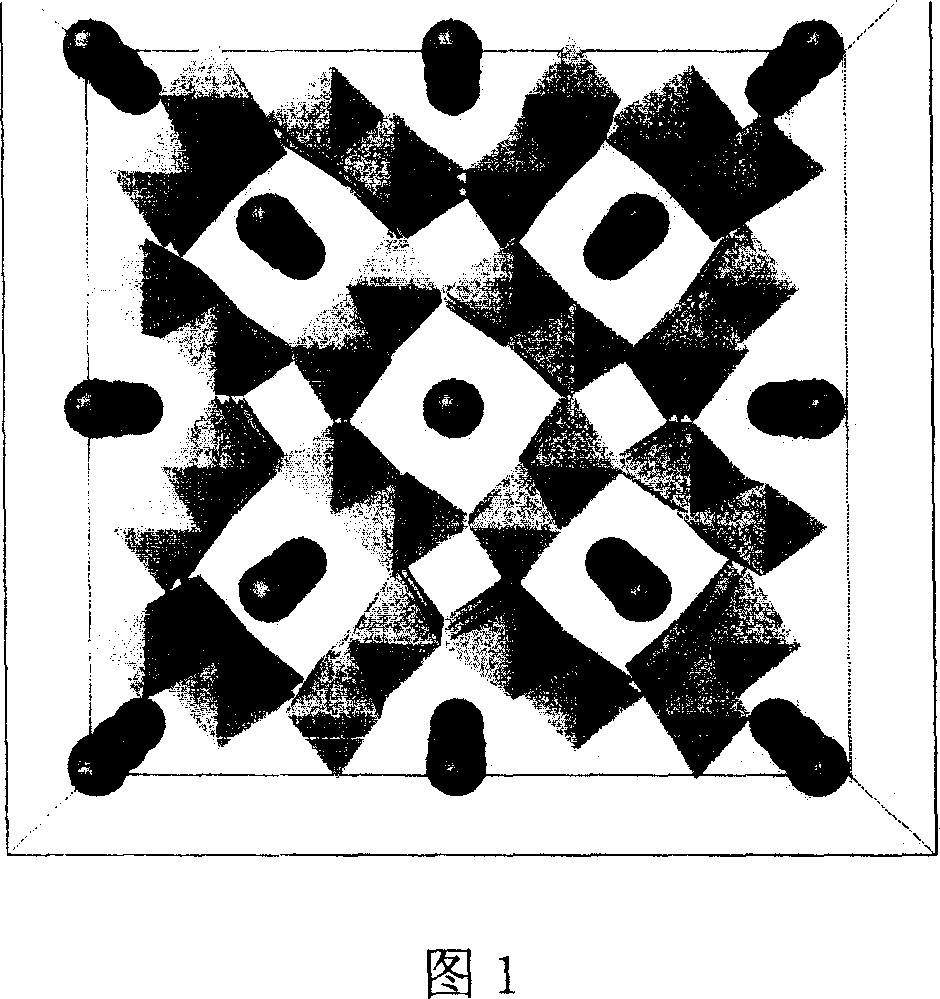

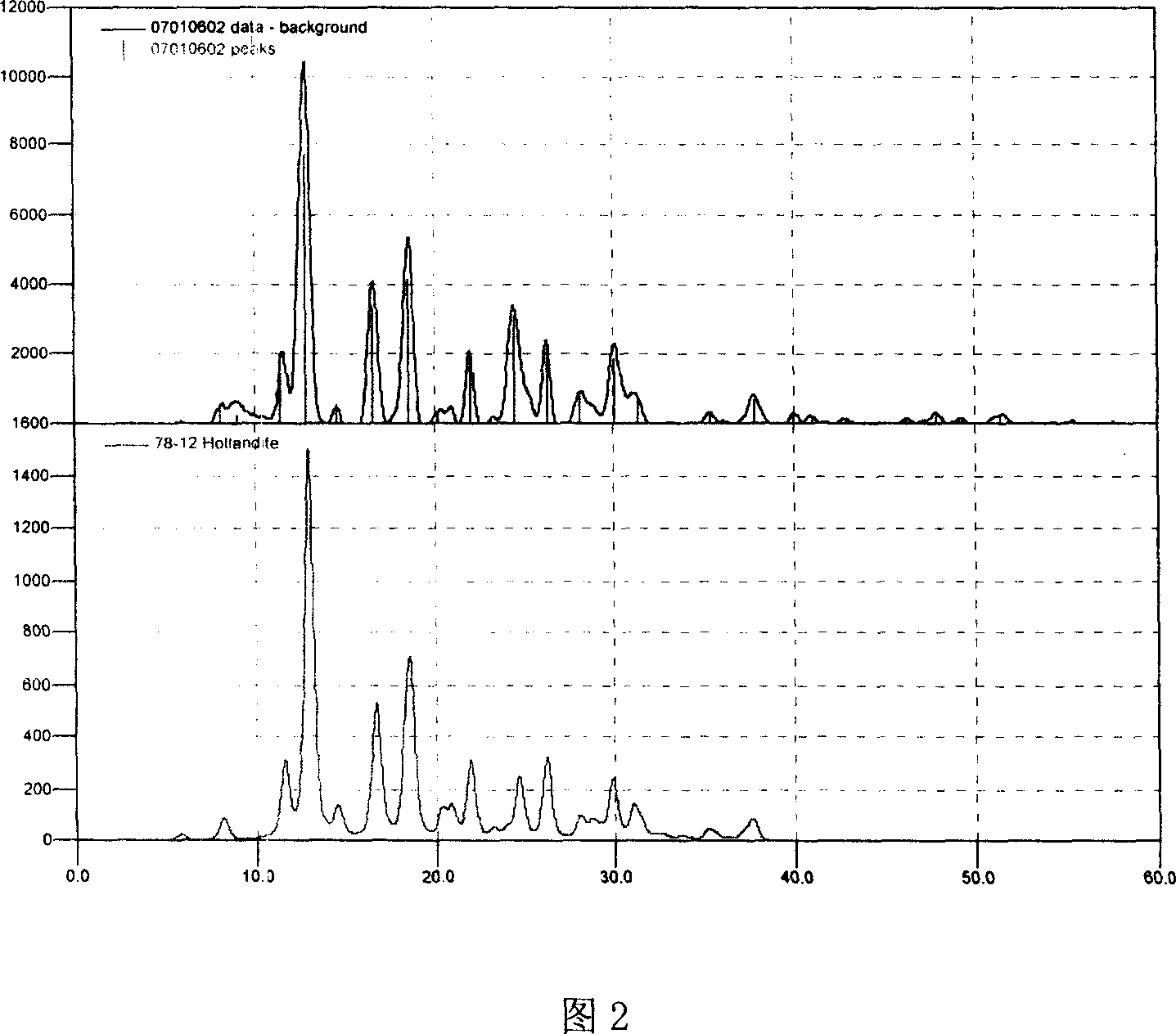

Preparing method and use for ankangite-type non-commensurability modulation structure material

A structural material and well-being technology, applied in the field of preparation and application of inorganic materials, can solve problems such as difficulty in achieving large-scale application, hindering development, artificial preparation processes and specific uses that have not been studied in detail, and achieve low cost, stable process, and low cost. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Raw material according to following ratio (molar ratio) BaCO 3 :TiO 2 :Al 2 o 3 =0.8:6.4:0.8 Weighing, according to the weight ratio of the mixture to deionized water and corundum balls is 1:2:2, add deionized water and corundum balls respectively, ball mill in a ball mill for 20h, and dry at 150°C , placed in a corundum crucible, and calcined at a high temperature of 1300 ° C for 2 hours to obtain the desired material.

Embodiment 2

[0026] Embodiment 2 Raw materials are according to the following ratio (molar ratio) Ba(NO 3 ) 2 :TiCl 4 : Al(NO 3 ) 3 9H 2 O:H 2 O=0.8: 6.4: 1.6: 500, make transparent solution, add additive citric acid, its addition is 3wt% of raw material quality, add additive polyethylene glycol, its additive amount is 2wt% of raw material quality, mix homogeneously, After removing moisture at 200°C, it was calcined at 1200°C for 3 hours to obtain the desired material.

Embodiment 3

[0027] Embodiment 3 Raw material according to the following ratio (molar ratio) Ba(NO 3 ) 2 :TiCl 4 : Cr(NO 3 ) 3 9H 2 O:H 2 O=0.8: 6.4: 1.6: 500, make transparent solution, add additive citric acid, its addition is 3wt% of raw material quality, add additive polyethylene glycol, its additive amount is 2wt% of raw material quality, mix homogeneously, After removing moisture at 200°C, it was calcined at 1200°C for 3 hours to obtain the desired material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com