Device for controlling the connection to be displaced temporary of two unit which can be pressurized with pressure medium with pressure medium source

A pressure medium and unit technology, applied in the direction of mechanical equipment, non-mechanical actuated valves, engine components, etc., can solve problems such as insufficient safety, reliability, and poor quality, and achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

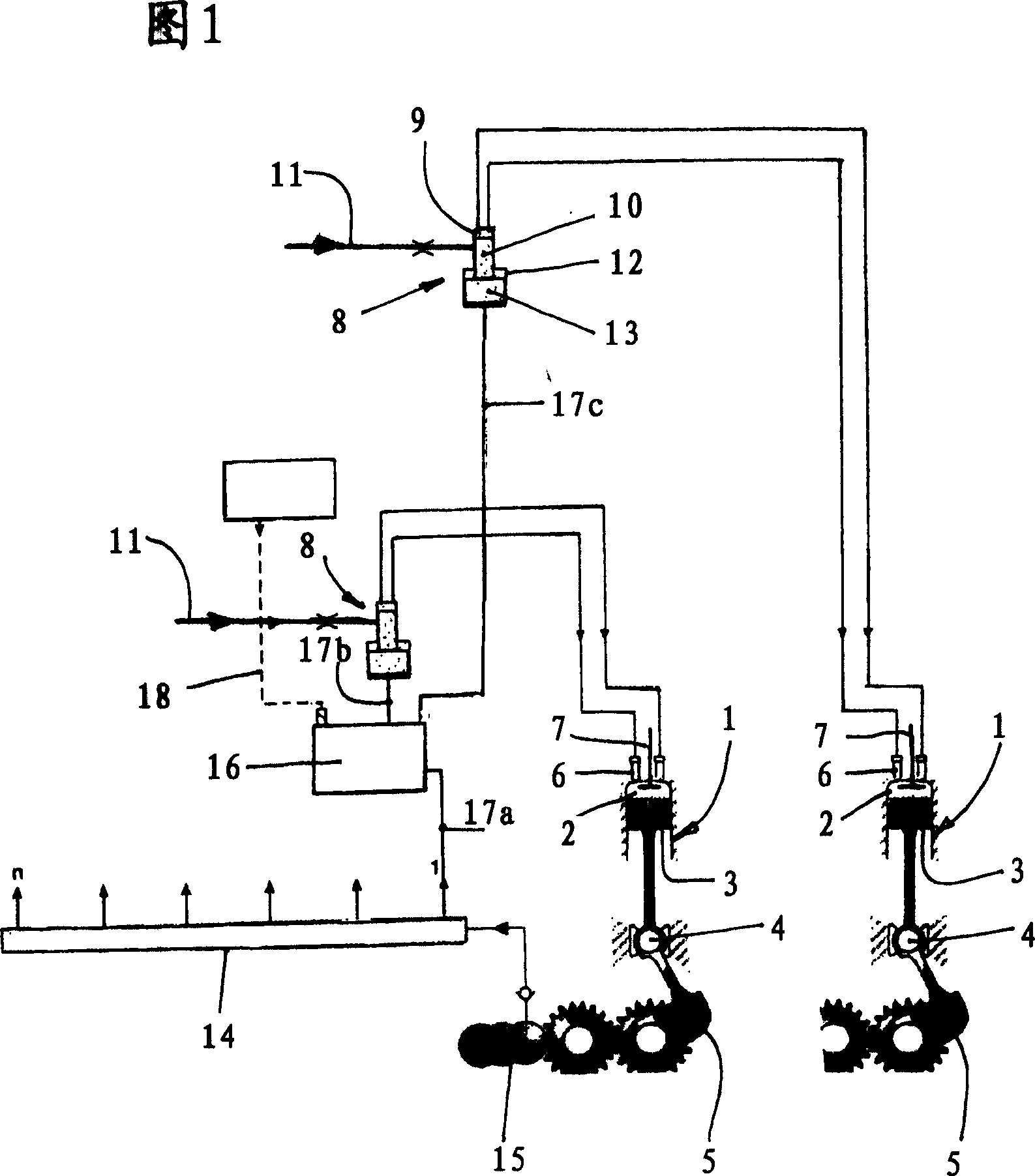

[0022] The main application field of the present invention is, for example, a two-stroke large diesel engine that can be used as a marine engine. In this regard, it involves engines with lower speeds and larger piston strokes. This type of engine usually includes multiple cylinders arranged in rows. The basic structure and working methods of such engines are known.

[0023] Figure 1 schematically shows two cylinders 1. Each cylinder 1 has a combustion chamber 2 bounded by a piston 3 that moves up and down, where the piston interacts with a crankshaft 5 via a crosshead 4. The combustion chamber 2 is charged with air through an intake port not shown in detail here, which is arranged in the cylinder liner and controlled by the piston 3 moving up and down, and is charged with fuel through a fuel injection valve 6 arranged in the area of the cylinder head. Each cylinder is provided with two fuel injection valves 6 in the example shown in the figure. The exhaust gas generated during c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com