Fryer

A cooker and oil layer technology, which is applied to utensils for frying things in oil, household utensils, applications, etc., can solve the problems of shortening the service life of oil, shortening the service life of cooking oil, not having sufficient effect, etc. Frequency of changing oil, preventing deterioration of working environment, effect of good cooking environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

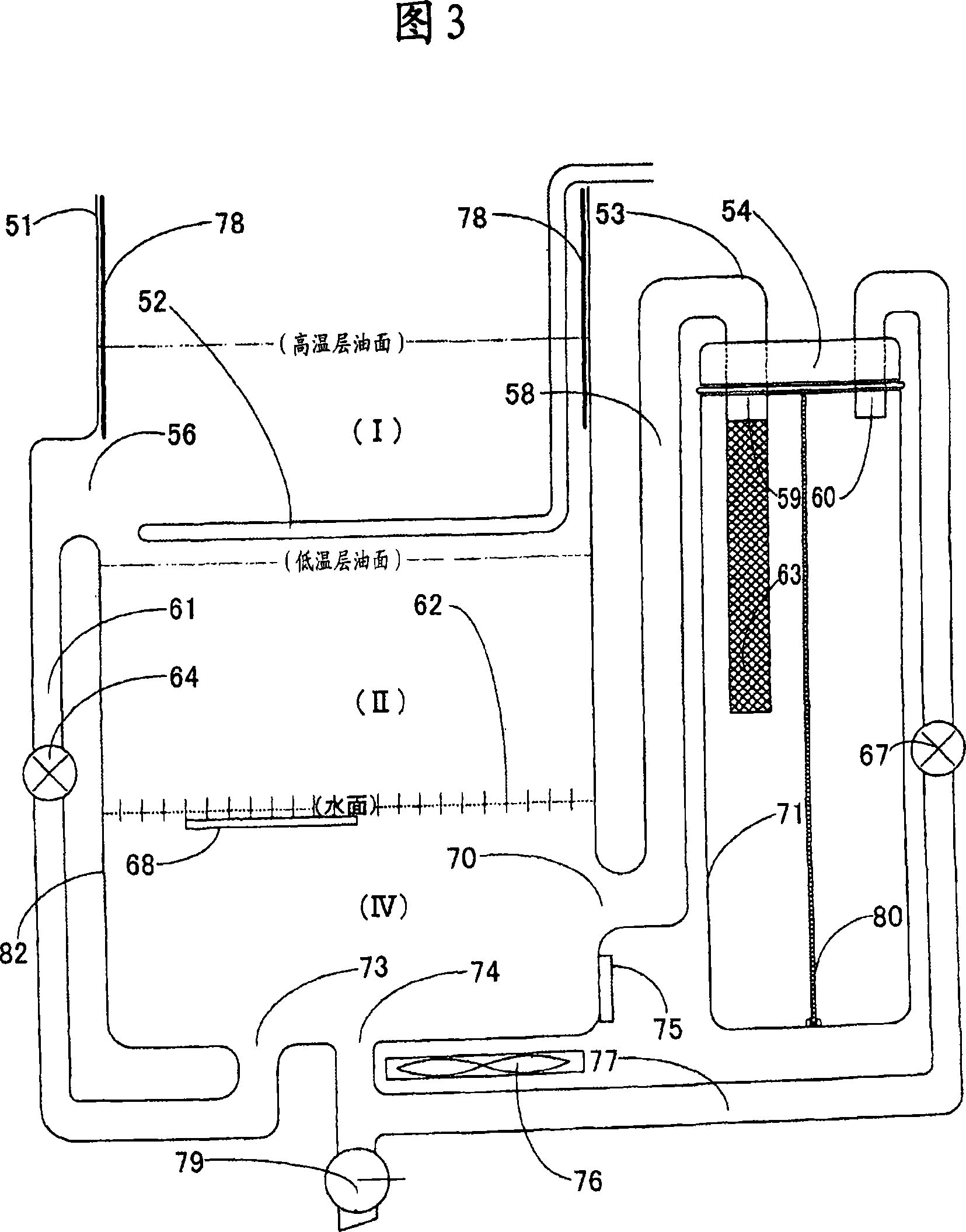

[0050] Embodiments of the present invention will be described below.

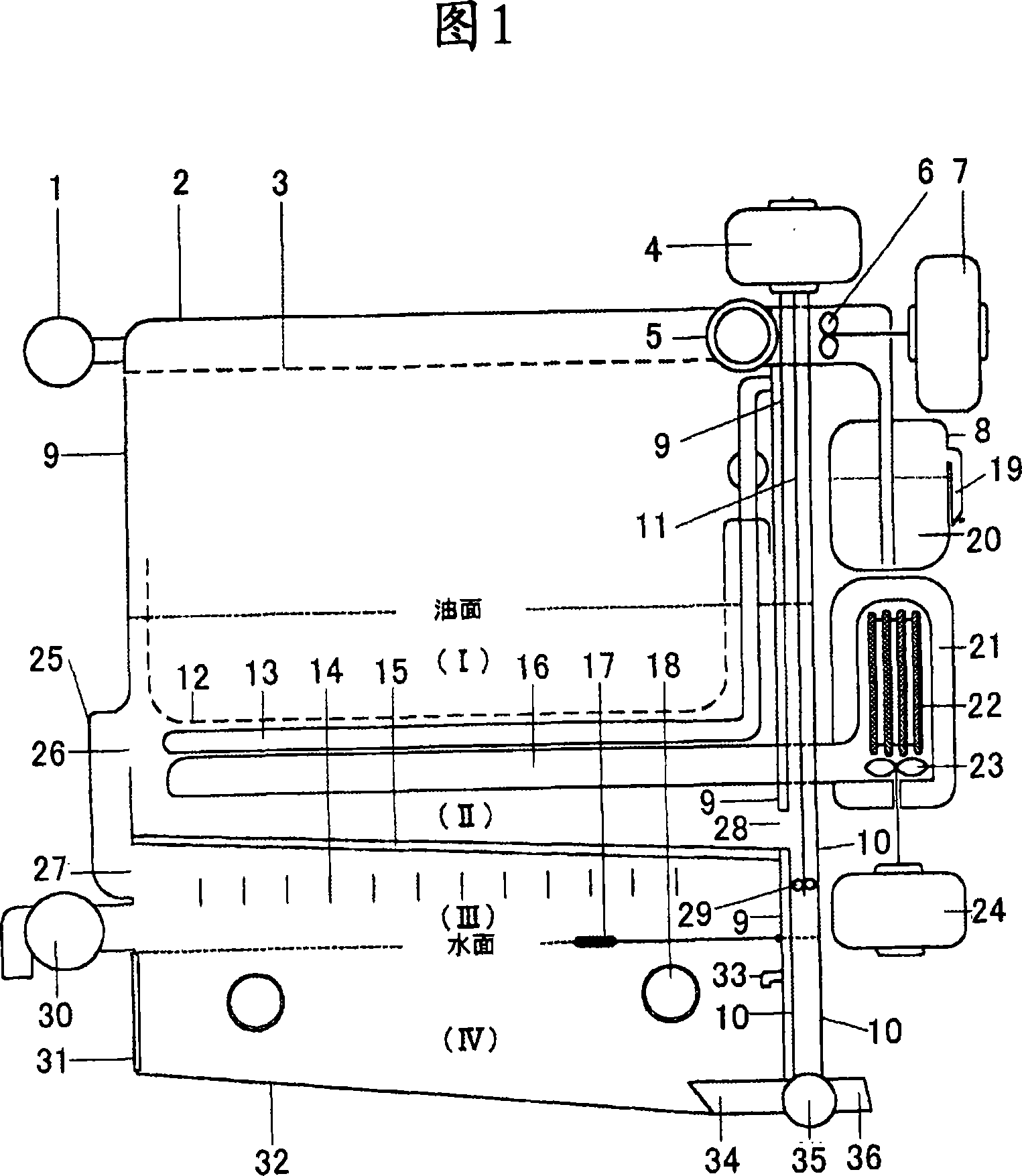

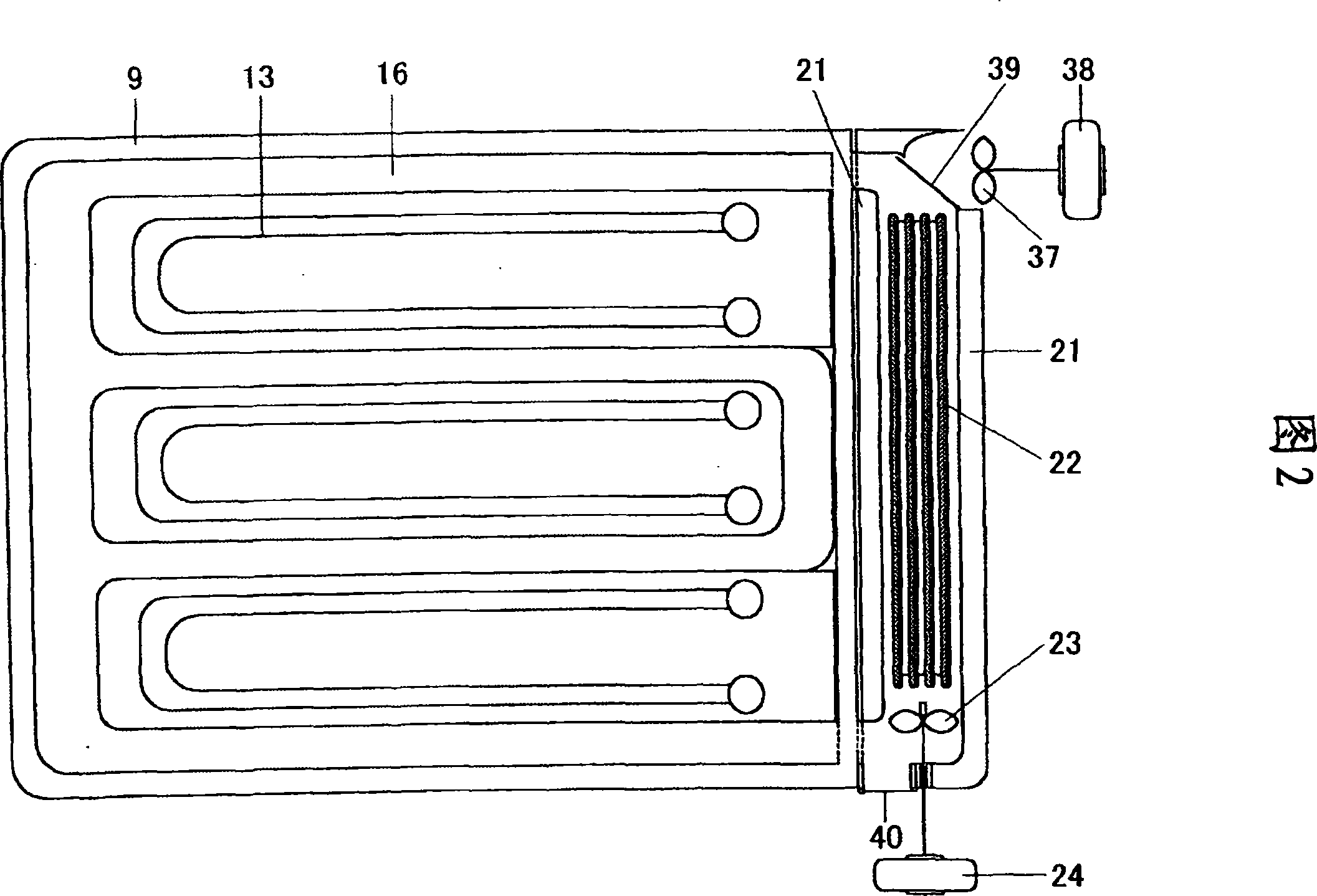

[0051] 1 and 2 show a fryer range according to a first embodiment of the present invention. Fig. 1 is an explanatory side view of a frying pan range, 9 is an oil tank, 32 is a water tank, and 13 is an electric heater for heating cooking oil in the oil tank. In the oil tank 9, a high-temperature cooking oil layer (I) is formed above the heater 13, and a low-temperature oil layer (II) with little deterioration of oil is formed below the heater 13, and a partition is provided under the low-temperature oil layer (II). 15. A water tank 32 is provided so as to be continuous with the lower side of the oil tank 9 , and an oil storage layer (III) for storing oil is formed between the water layer (IV) in the water tank 32 and the above-mentioned separator 15 .

[0052] In order to keep the cooking oil temperature, a temperature sensor (not shown) is set on the cooking oil layer (I) for frying and cooking. Once the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com