Method of locating the head of the plastic extruding forming mould and the mould head

A technology of extrusion molding and positioning method, which is applied to the die head positioning and die head field of plastic extrusion molding moulds. Improved accuracy and reliability, reduced positioning accuracy drop, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

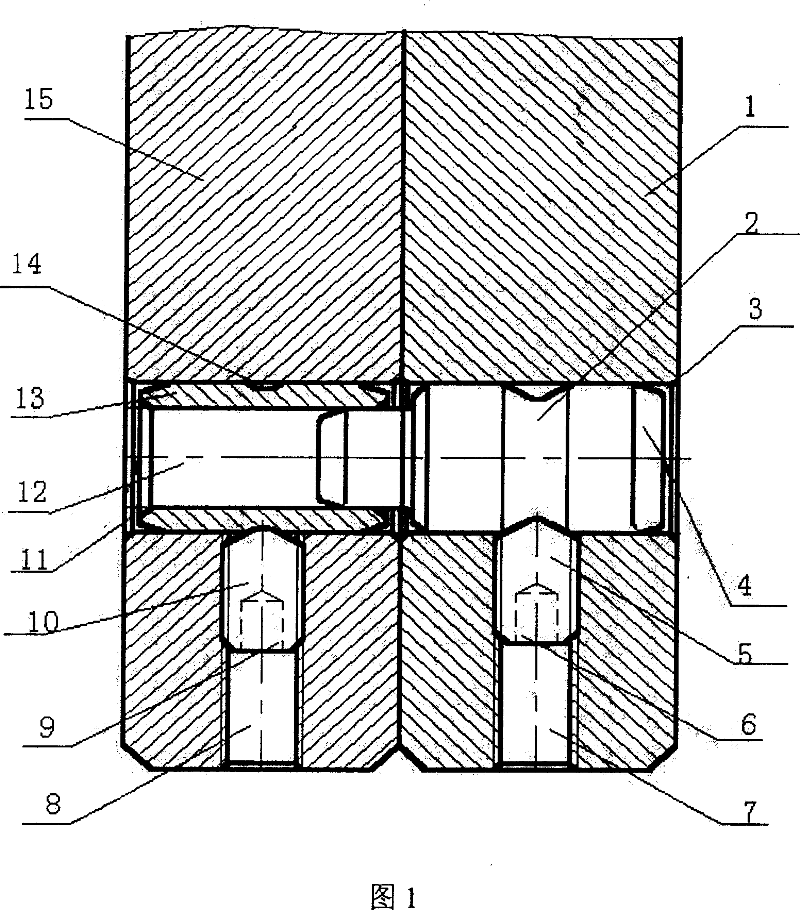

[0014] The present invention is a die head of a plastic extrusion molding die, which is composed of several die head plates, as shown in Figure 1, which is a schematic diagram of the positioning of any two adjacent die head plates in the present invention. Positioning holes 3 and 11 are respectively provided at the corresponding positions of the two adjacent plates 1 and 15 . A positioning pin 4 and a positioning pin sleeve 13 are respectively housed in the positioning holes 3 and 11. One end of the locating pin 4 has a pin post that is compatible with the through hole 12 in the locating pin sleeve 13. same diameter. The outer circular surface of locating pin 4 and locating pin sleeve 13 is suitable with the locating hole 3,11 of adjacent plate 1 and plate 15 respectively, and for ease of installation, the diameter of locating hole 3 and 11 is identical.

[0015] In order to make the locating pin 4 and the locating pin sleeve 13 realize the static fit with the respective pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com