Insulation platform for live operation

A live working and platform technology, applied in electrical components, cable installation, cable installation devices, etc., can solve the problems of inability to carry large equipment loads and the limited bearing capacity of insulating telescopic arms, and achieve the effect of simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

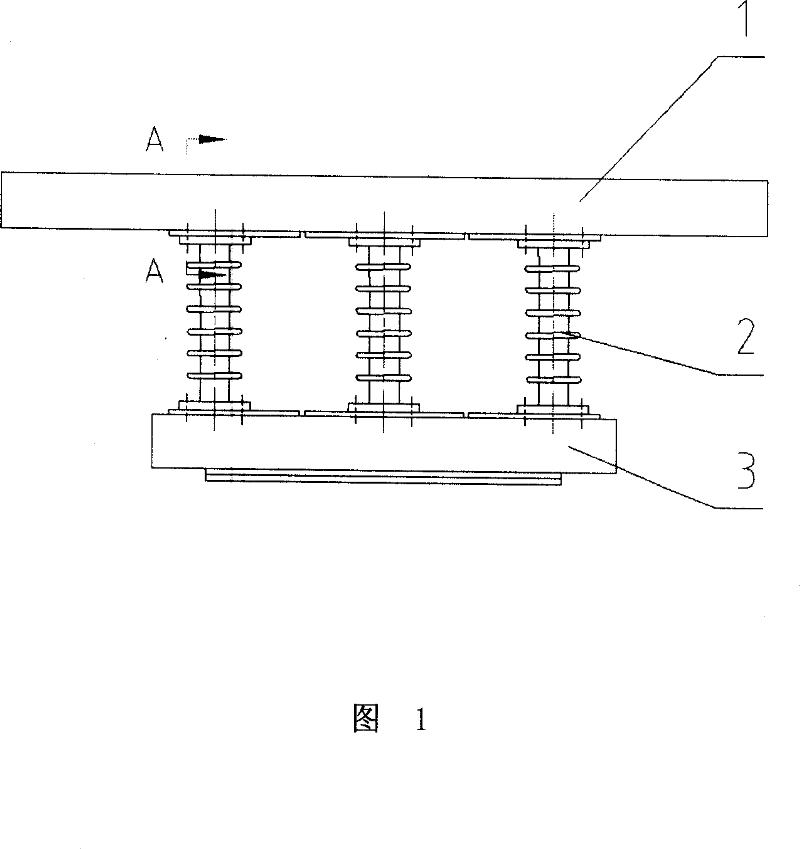

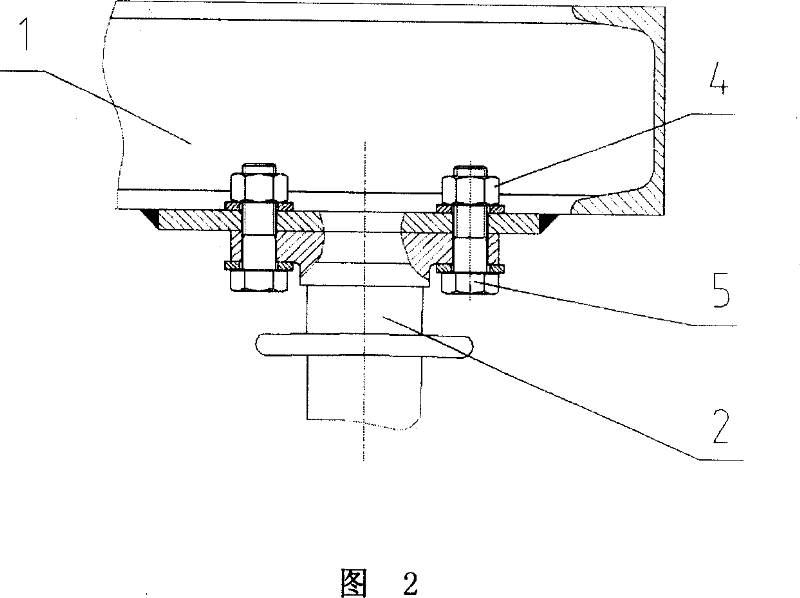

[0012] The present invention will be further described in conjunction with the accompanying drawings: first, determine the load and size of the platform according to the requirements, and select 8 insulators of corresponding specifications; cut the channel steel, steel plate and other profiles according to the determined size, and weld them into the installation platform frame and connection Platform frame; 8 steel plates with holes are welded at the connection between the installation platform frame and the flange of the insulator support; 8 steel plates with holes are welded at the connection between the platform frame and the flange of the insulator support. The connecting steel plate with holes is welded in the middle part under the platform frame. After welding and surface treatment, the 8 insulator pillars, the installation platform and the connection platform are fixed and connected together by bolts and nuts, and put into storage for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com