Seed shell automatic cracking machine of seedless watermelon

A seedless watermelon and shell breaking machine technology is applied in the directions of seed and rhizome treatment, shelling, pod removal, etc., which can solve the problems of high labor intensity, high production cost, low production efficiency, etc., so as to reduce labor intensity and reduce production. cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be further described.

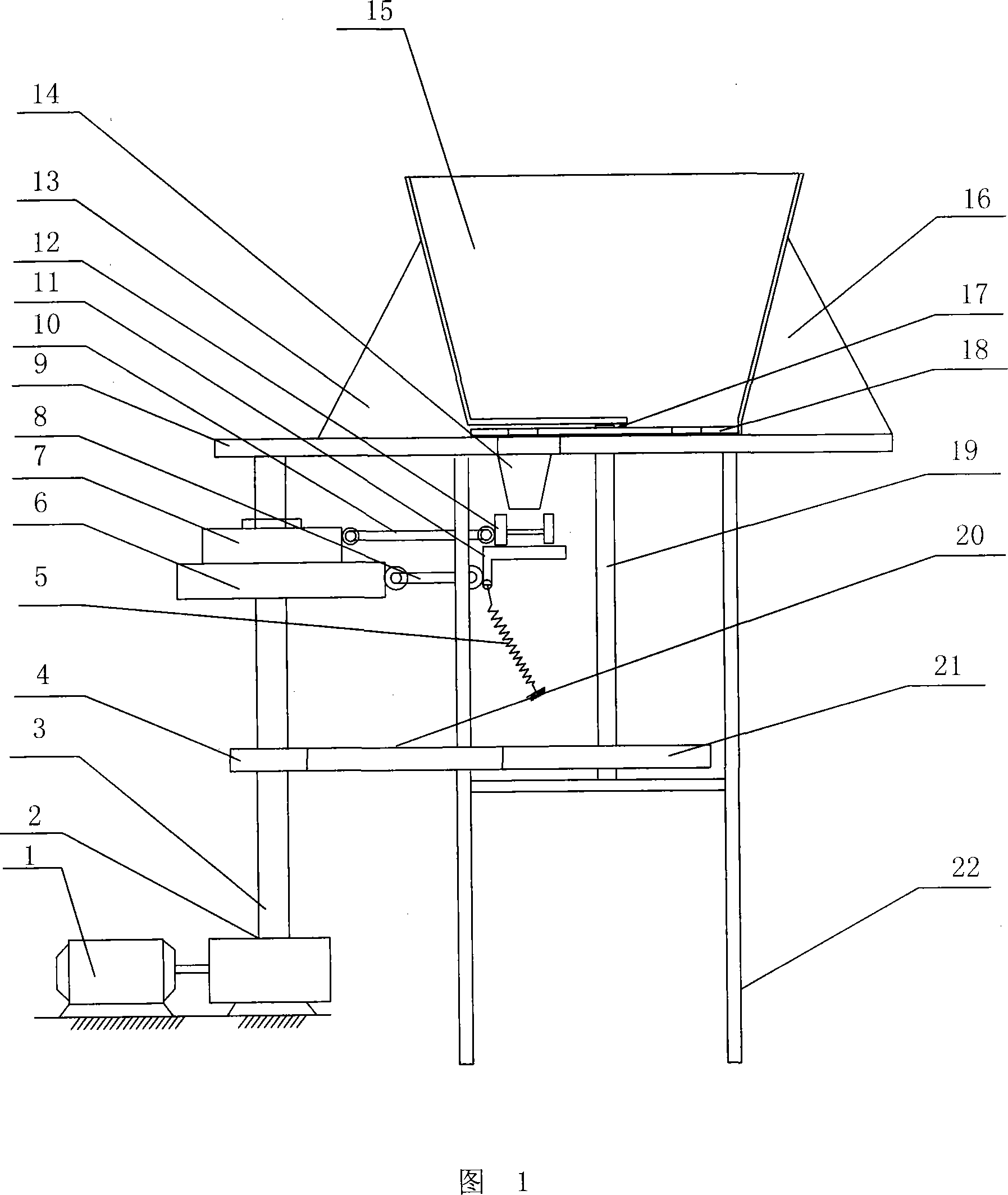

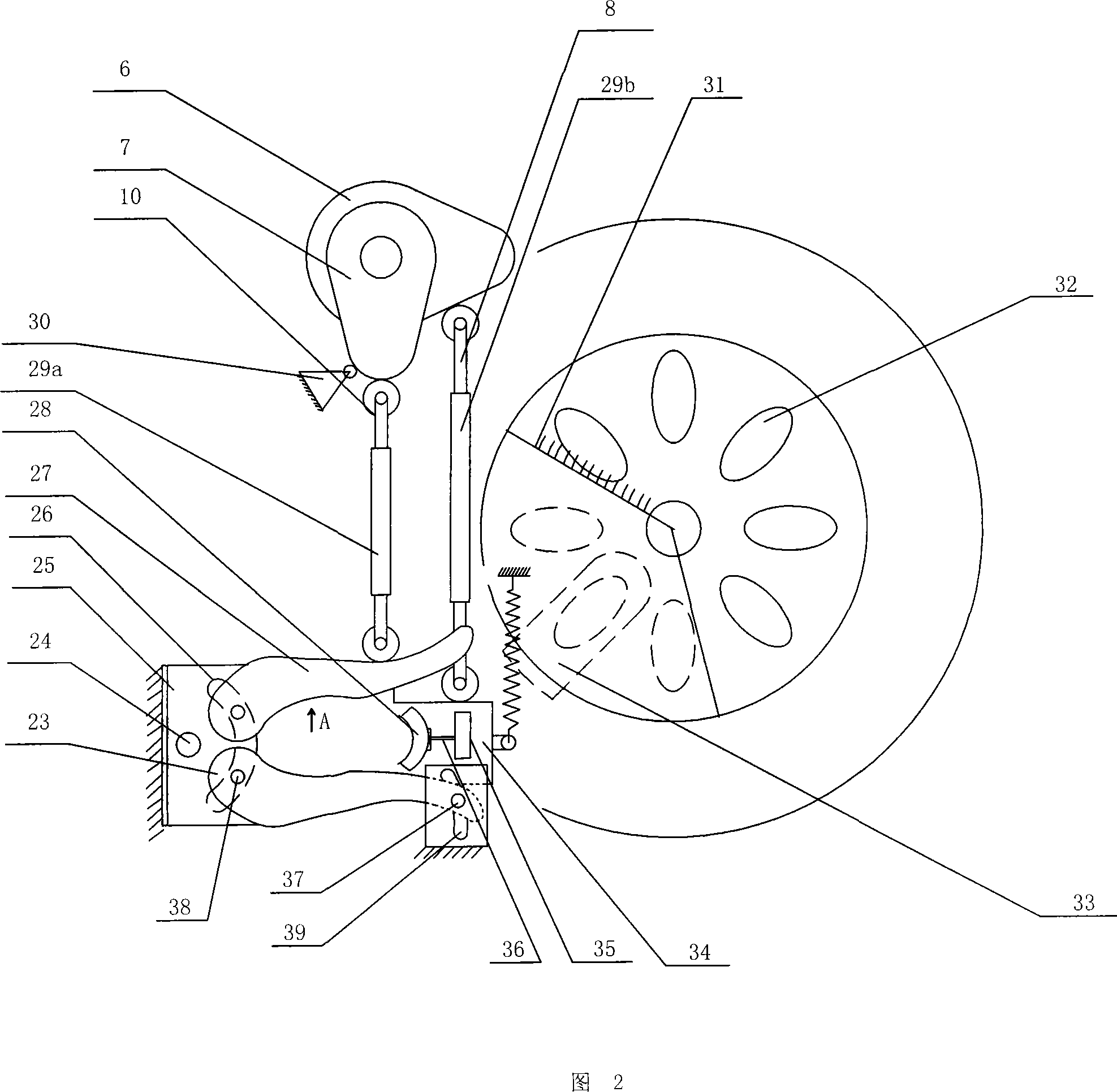

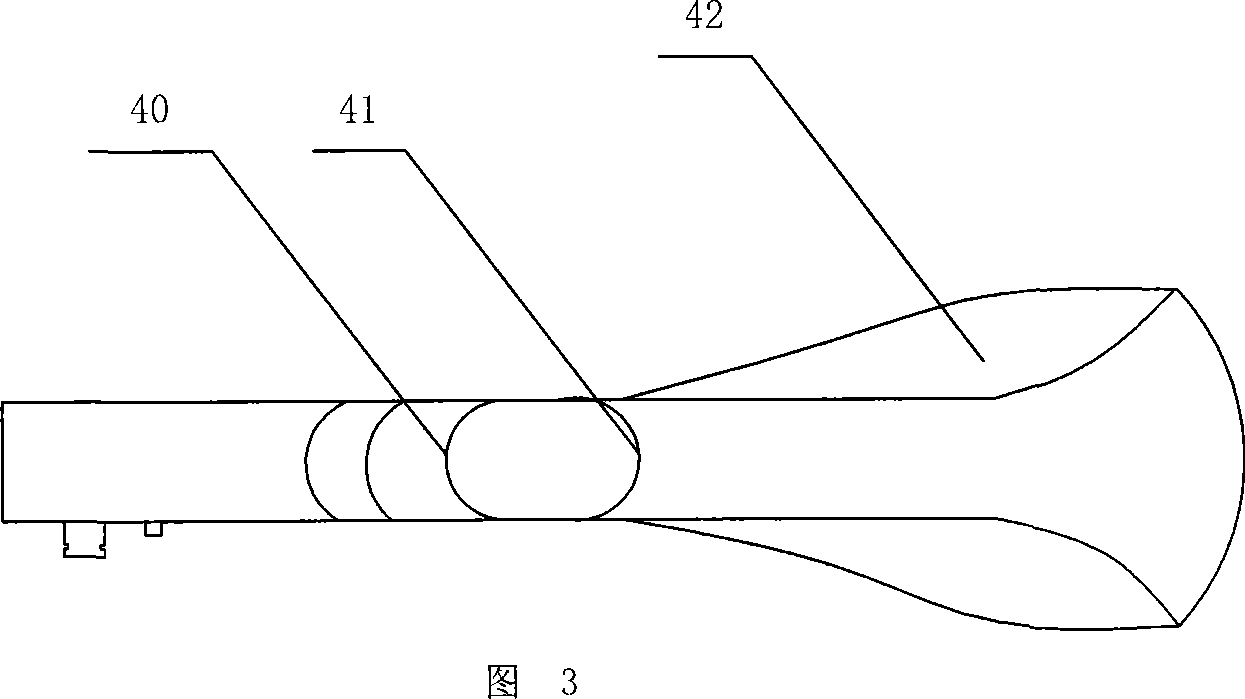

[0013] With reference to Fig. 1-3, seed grading device, seed breaking device, seed arrangement, adjustable device and power transmission device are installed on the present embodiment frame 22; Described seed grading device comprises funnel 15, has cleaning brush 31 The seed baffle plate 17, the rotating disk 18, the seed conduit 14 that are provided with the seed type hole 32, the funnel 15 links to each other with the seed baffle plate 17, the seed type hole rotating disk 18 is fixedly connected with the rotating shaft 19, and the rotating disk 18 below is close to the seed fixing pallet 33 , the seed conduit 14 is connected to the frame table 9, the seed-shaped holes 32 are evenly distributed on the turntable 18, and the funnel 15 is fixed on the frame table 9 through the support plate I13 and the support plate II16. Its working principle is: the seeds in the funnel 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com