Method for producing food level liquid carbon dioxide product

A liquid carbon dioxide and production method technology, applied in chemical instruments and methods, food preparation, inorganic chemistry, etc., can solve the problems of high energy consumption, low recovery rate, and difficult liquefaction, etc., to reduce energy consumption and reduce consumption , The effect of improving the recovery rate

Active Publication Date: 2010-12-01

HUNAN KAIMEITE GASES +1

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

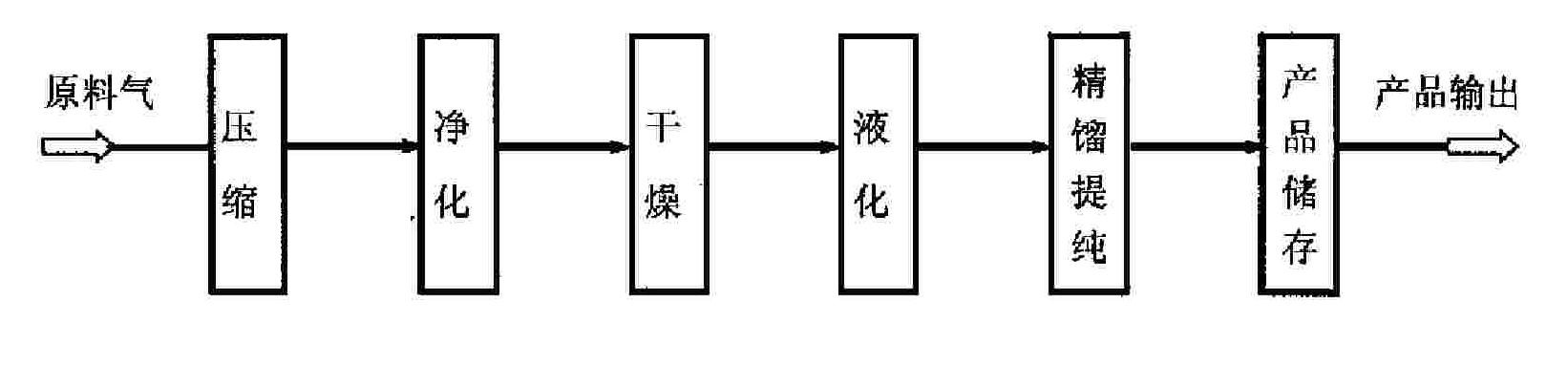

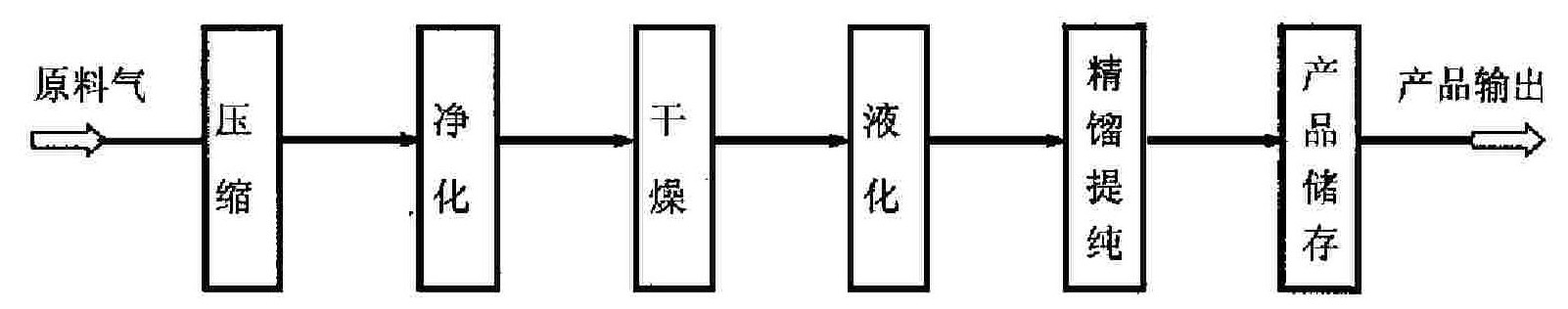

Patent No. 00116187.3 introduces a production method of food-grade liquid carbon dioxide. The production process includes raw material gas compression, desulfurization and other purification processes, drying, liquefaction and other processes. The liquefied carbon dioxide directly enters the product storage tank. Through this method, certain Pure liquid carbon dioxide, but because it cannot fully and effectively remove the N2, H2, CH4 and other components that may exist in the raw material gas, these components are light components, not easy to liquefy, and can be dissolved in a certain amount in liquid carbon dioxide, making The quality of product carbon dioxide is affected, and at the same time, the invention does not fully recover the cooling capacity in the process, resulting in large energy consumption, which does not meet the current development ideas of energy saving and consumption reduction, and circular economy; application number 200610092071. The method of absorbing carbon dioxide in a liquid, and then desorbing it to produce carbon dioxide from the absorbing liquid has a low recovery rate and has disadvantages such as easy loss of absorbing liquid, secondary pollution, and high energy consumption.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

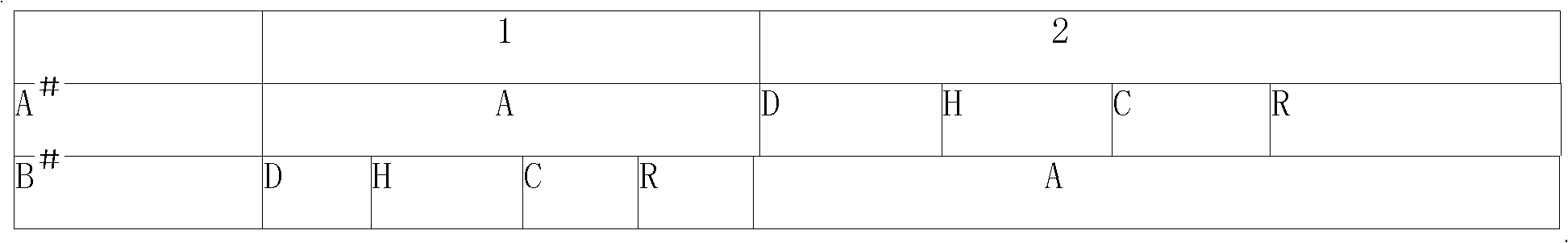

The invention relates to a method for producing edible liquid carbon dioxide product, characterized in that in compression step, the distribution of the third-stage outlet gas of compressor is adjusted by an adjusting valve, to supply needed thermal source to distillation via the compressed gas transmitted to a purifying tower, in the purifying step, some carbon dioxide gas and foul gas of purifying tower are discharge from tower top as splash steam to be throttled, expanded and reduced temperature via an adjusting valve A, to be feedback to a heat exchanger at the upper part of the purifyingtower, to exchange heat with ascending splash steam in tube, and reduce pressure to 0.05MPa via an adjusting valve B, to be feed into purifying process to exchange heat with material gas to recycle cold as the regenerated gas of purifying or drying process. The invention uses adjusting valves A, B to control pressure discharge of purifying tower, to assure the stable pressure of purifying tower. The recycle rate of carbon dioxide of invention is at least improved 3%, while the consumption is at least reduced 5% and the carbon dioxide can reach the standard of edible carbon dioxide.

Description

A kind of production method of food-grade liquid carbon dioxide product technical field The invention relates to a production method of a food-grade liquid carbon dioxide product. Background technique Carbon dioxide is an important raw material for industrial production, widely used in metallurgy, iron and steel, petroleum, chemical industry, electronics, food, medical treatment and other fields, especially in food industry applications, such as modified atmosphere preservation of food, beverage industry applications, Food refrigeration and freezing applications, supercritical extraction, etc. There are two types of carbon dioxide-rich gas sources available for industrial recovery, namely natural carbon dioxide gas source and industrial by-product gas source carbon dioxide. Natural carbon dioxide gas is produced in some natural gas fields. Carbon dioxide-rich gas fields have a carbon dioxide content of 15-99%. In Guangdong, Shandong, Jiangsu and other places in China, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A23L1/00A23L2/54C01B31/20C01B32/50

CPCY02A50/20

Inventor 祝恩福魏玺群唐莉

Owner HUNAN KAIMEITE GASES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com