Method for recovering the ink box of the ink-jet printer

An inkjet printer, ink cartridge recycling technology, applied in chemical instruments and methods, cleaning methods and utensils, printing and other directions, can solve the problems affecting the quality of recycled ink cartridges, unable to remove residual ink stains, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

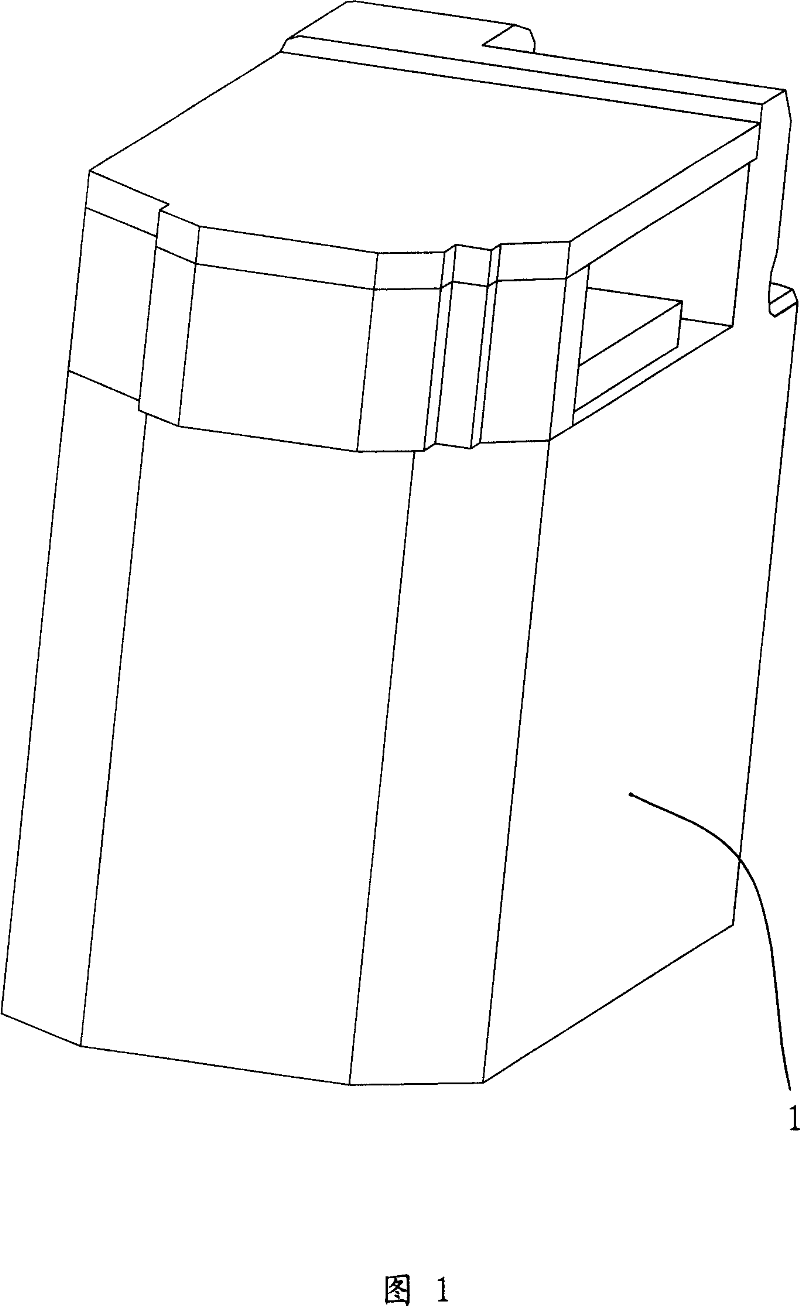

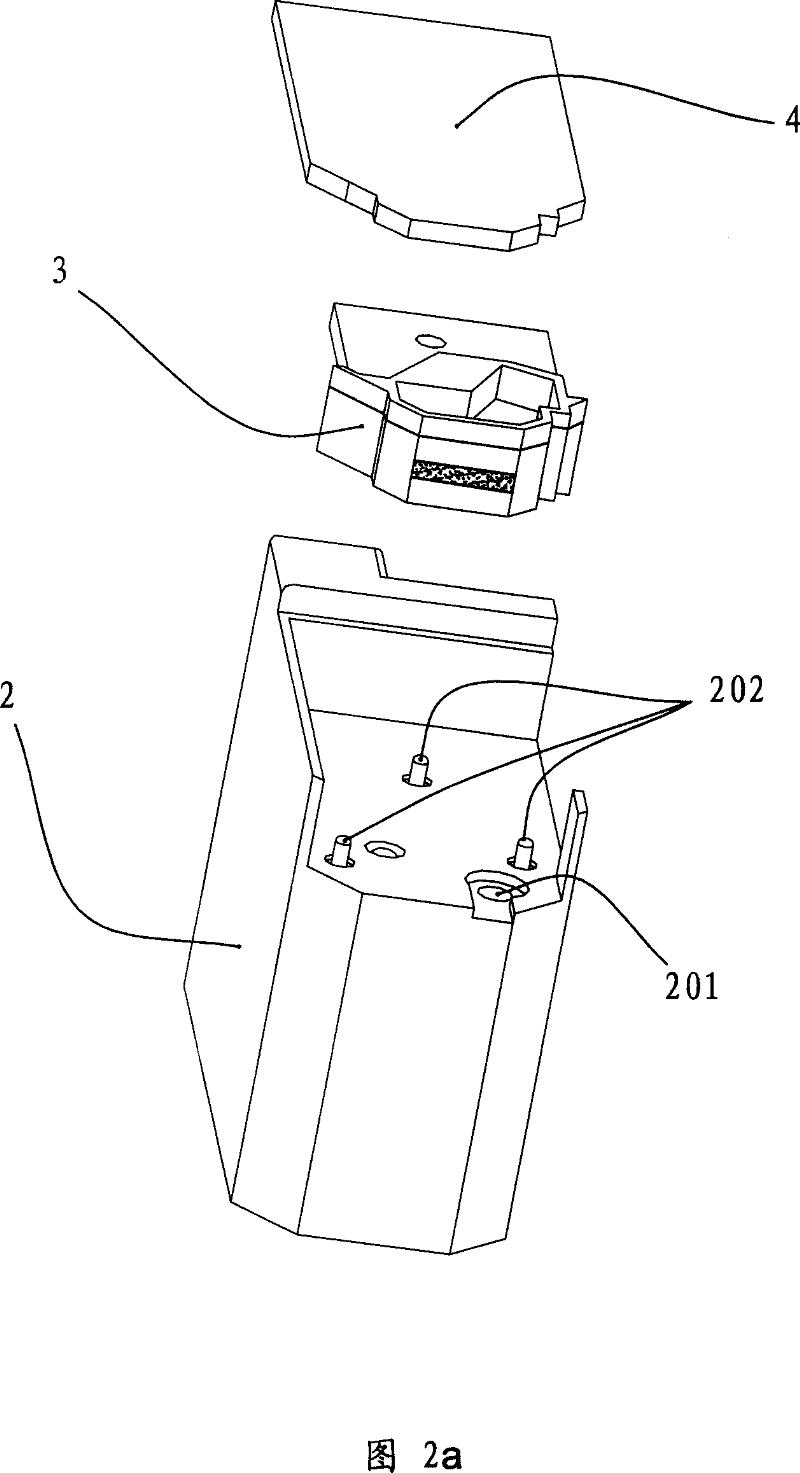

[0024] As shown in Figures 1 and 2, the inkjet printer ink cartridge 1 applying the recycling method of the present invention includes a cartridge body 2 and a recording head 3 structurally. The recording head 3 is fixed on the bottom of the box body 2 through the positioning bottom plate 4 .

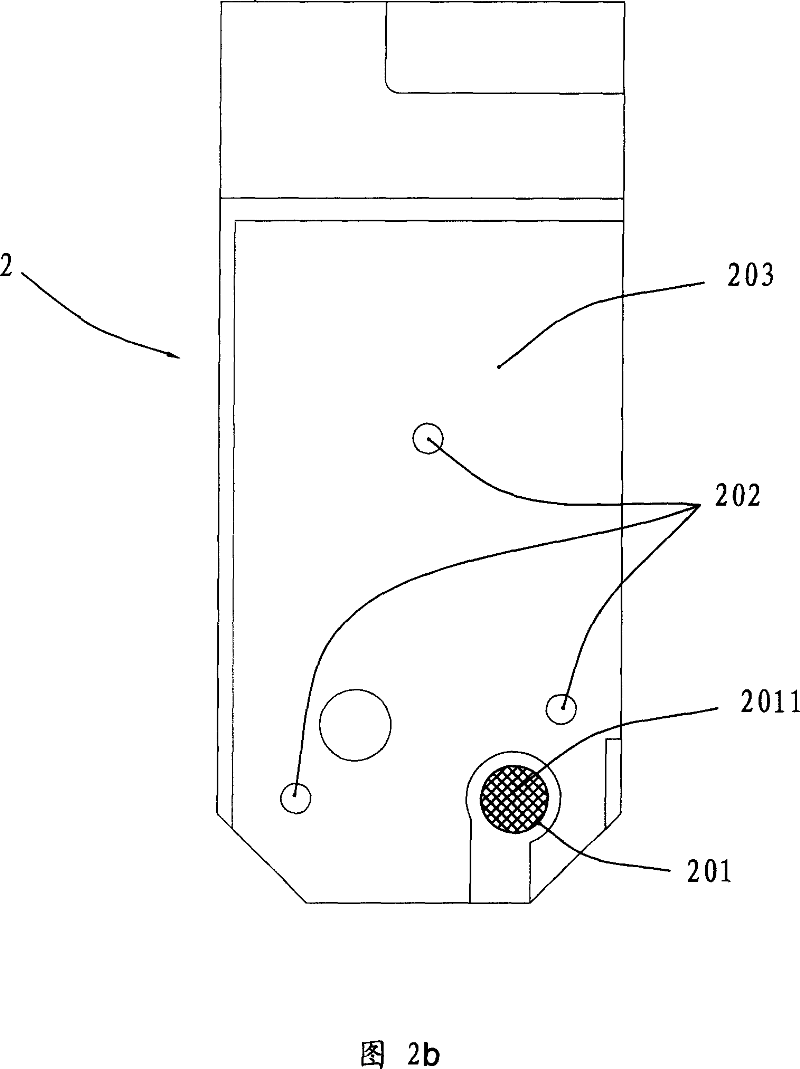

[0025] The inside of the box body 2 is provided with an ink storage chamber for containing ink and a corresponding negative pressure generating mechanism (not shown), such as porous materials such as sponge. Its bottom is provided with an ink supply channel 201 communicating with the ink storage chamber and three positioning posts 202 protruding outward. A filter 2011 is further provided at the end of the ink supply channel 201 close to the ink storage chamber (as shown in FIG. 2b ).

[0026] As shown in FIGS. 3 and 4 , the nozzle 301 of the recording head 3 is fixed on one side of the substrate 302 , and the ink delivery tube 303 protrudes from the opposite side of the substrate 302 ....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap