Pulseless type output micro-pump based on electromagnetic drive

An electromagnetic-driven, pulsation-free technology, applied to pumps with flexible working elements, pumps, machines/engines, etc., can solve the problems of waste, short drug effect time, etc., and achieve low cost, simple structure, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

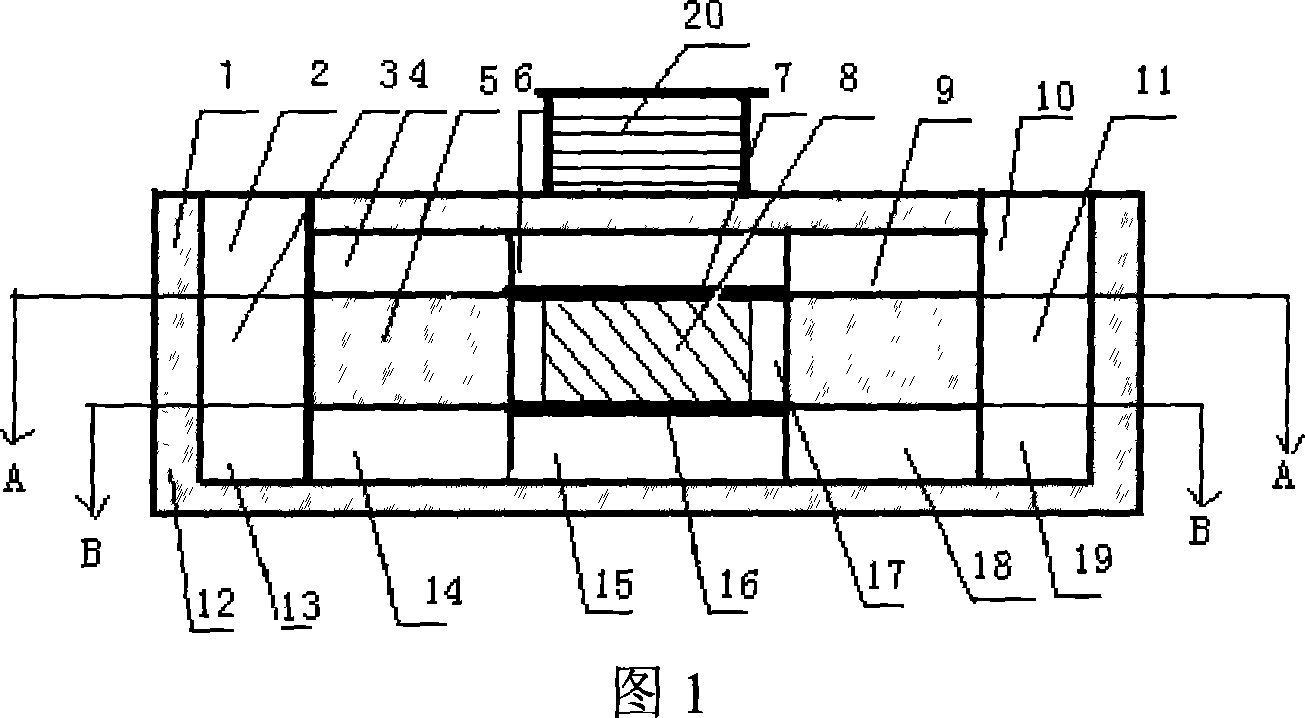

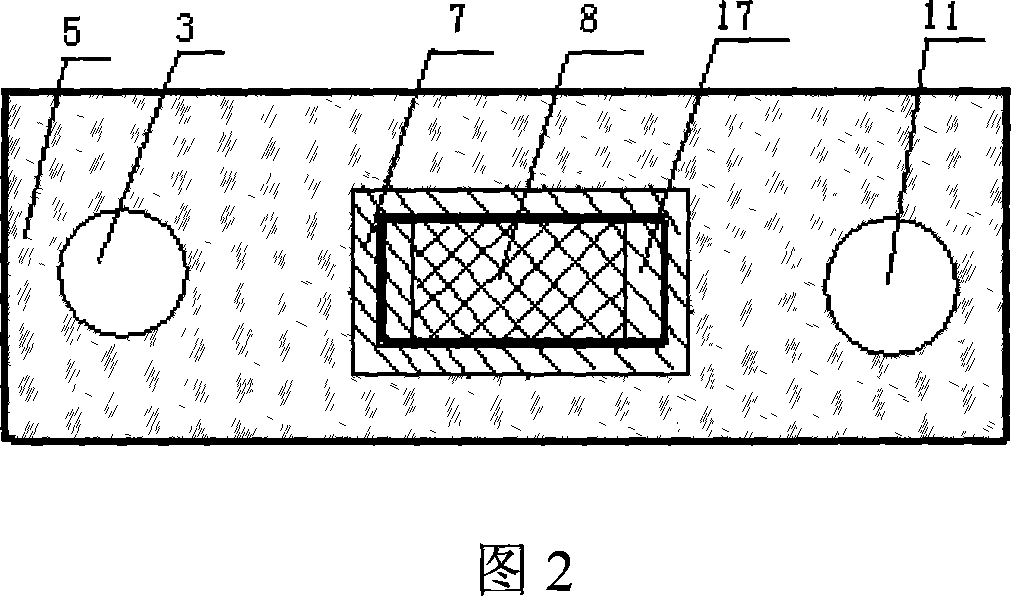

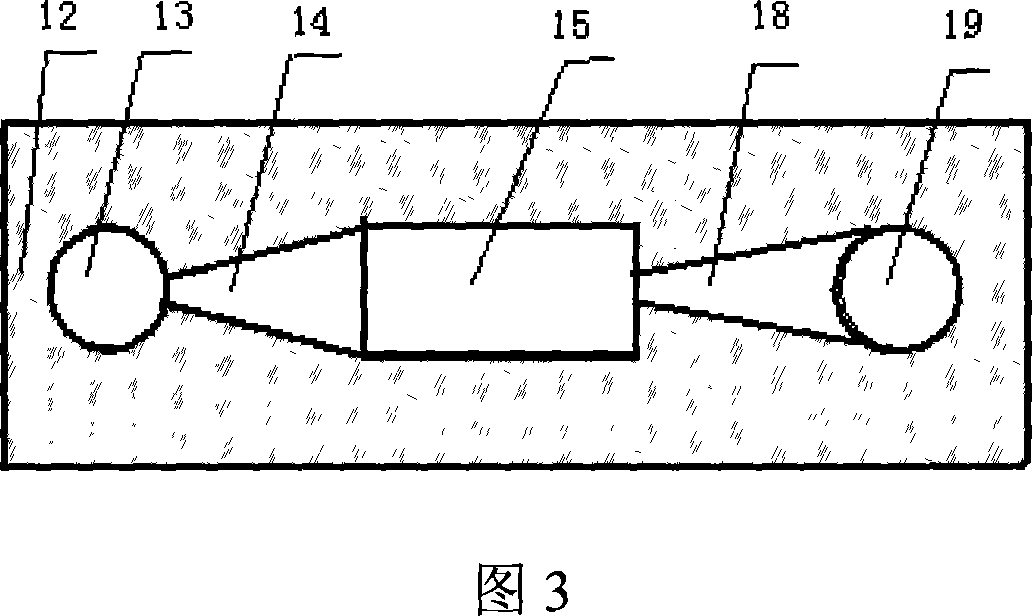

[0022] As shown in Figure 1, Figure 2, and Figure 3, the pump body is divided into three parts: upper, middle and lower. The upper pump body 1 is provided with an upper pump chamber 6, which is connected to the water inlet and outlet holes 2, 10 through two left and right cone valves 4,9. There is a driving chamber 17 in the middle of the middle pump body 5, and there are water inlet and outlet holes 3, 11 on both sides, and they are all vertically corresponding to the upper pump chamber. The driving magnet 8 is placed in it, and the two films 7, 16 are respectively fixed on the driving chamber. Cavity 17 up and down. The lower pump body has a lower pump chamber 15 corresponding to the upper pump body. The lower pump chamber is also connected to the water inlet and outlet holes 13 and 19 through two cone valves 14,18, and the taper angle of each cone valve is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com