Method for measuring metal pipes thick anisotropy index

A metal pipe and thickness anisotropy technology, which is applied in the field of measuring the thickness anisotropy index of metal pipes to achieve accurate evaluation and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Example 1: Detection of thickness anisotropy index of 20# steel pipe

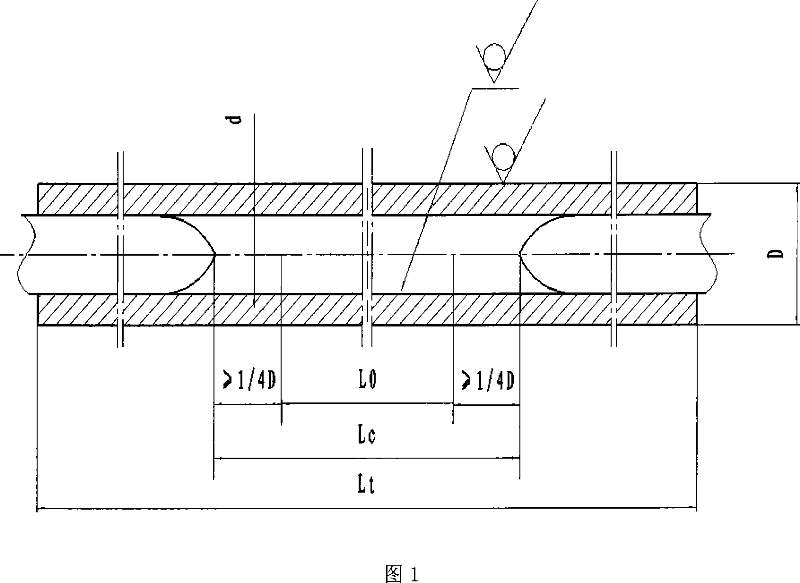

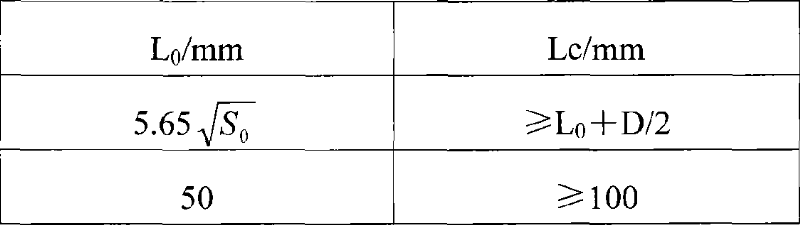

[0023] 1. Sampling according to GB / T 228-2002 tensile standard for pipes with stoppers.

[0024] 2. Measure the wall thickness t of the pipe to be 3mm, the outer diameter D to be 32mm, and the inner diameter d to be 26mm.

[0025] 3. The safety standard stipulates that the tensile test should be carried out on a 100KN vertical hydraulic tensile testing machine.

[0026] 4. When the sample is stretched to the engineering strain level of 10-15%, measure the outer diameter D of the sample 1 For: 30.4mm.

[0027] 5. According to the model 1 4 π ( D 2 - d 2 ) tL = 1 4 π ( D 1 2 ...

example 2

[0030] Example 2: Detection of thickness anisotropy index of 304 stainless steel pipe

[0031] 1. Sampling according to GB / T 228-2002 tensile standard for pipes with stoppers.

[0032] 2. Measure the wall thickness t of the pipe to be 5mm, the outer diameter D to be 40mm, and the inner diameter d to be 30mm.

[0033] 3. The safety standard stipulates that the tensile test should be carried out on a 100KN vertical hydraulic tensile testing machine.

[0034] 4. When the sample is stretched to the engineering strain level of 10-15%, measure the outer diameter D of the sample 1 For: 38.4mm.

[0035] 5. According to the model 1 4 π ( D 2 - d 2 ) tL = 1 4 π ( D 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com